PEX-1000 Series

Print Engine Service Manua

l

42

42

5. MAINTENANCE

This session presents the clean tools and methods to maintain your printer.

Please use one of following material to clean the printer.

Cotton swab (

Head cleaner pen

)

Lint-free cloth

Vacuum / Blower brush

100%

ethanol

2. The cleaning process is described as following

Printer Part

Method

Interval

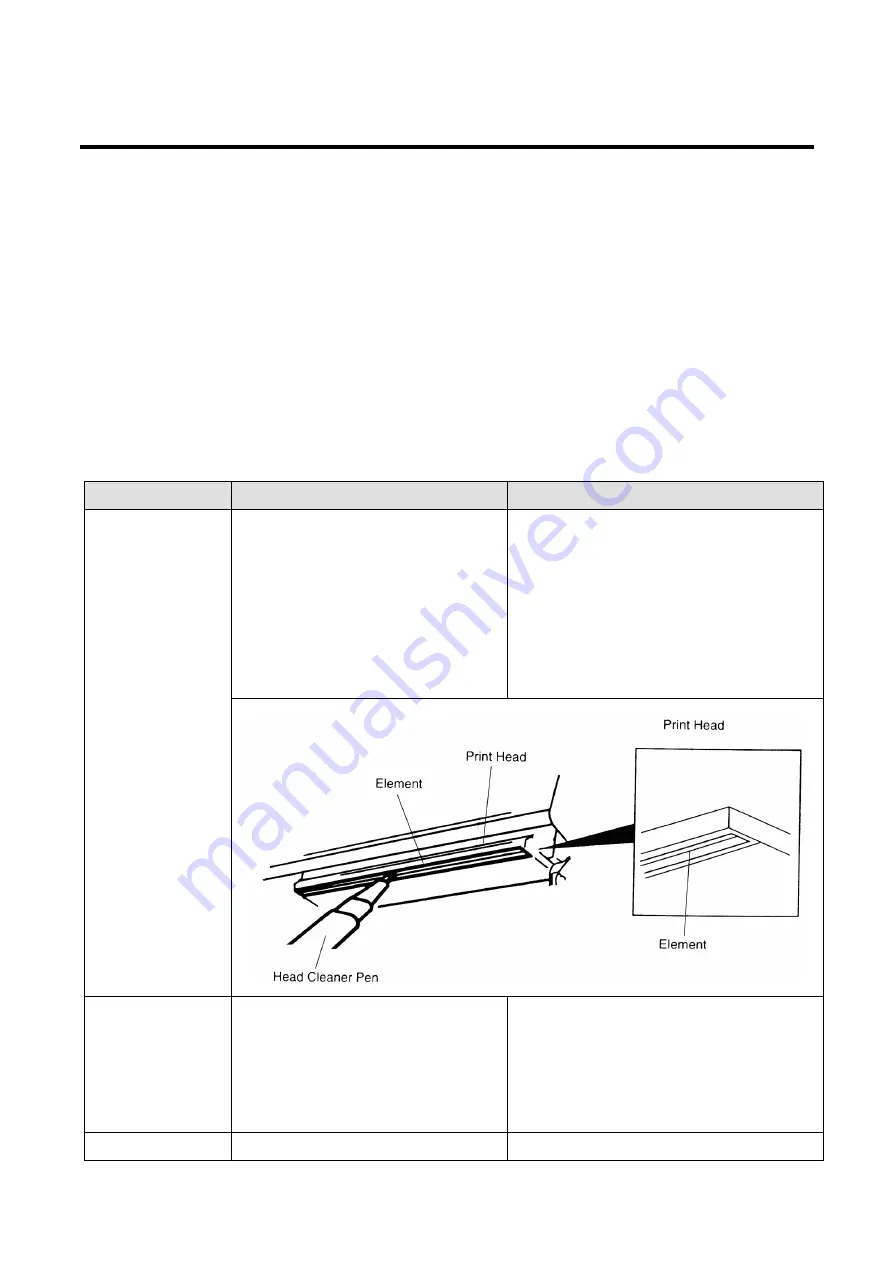

Print Head

1. Always turn off the printer

before cleaning the print head.

2. Allow the print head to cool for

a minimum of one minute.

3. Use a cotton swab (Head

cleaner pen) and 100% ethanol

to clean the print head surface.

Clean the print head when changing a

new ribbon roll

Platen Roller

1. Turn the power off.

2. Rotate the platen roller and

wipe it thoroughly with a cotton

swab, or lint-free cloth soaked

with clean water..

Clean the platen roller when changing

a new ribbon roll

Tear Bar/Peel

Use the lint-free cloth with 100% As needed