Summary of Contents for TTP-245 series

Page 1: ...SERVICE MANUAL TTP 245 343 THERMAL TRANSFER DIRECT THERMAL BAR CODE PRINTER ...

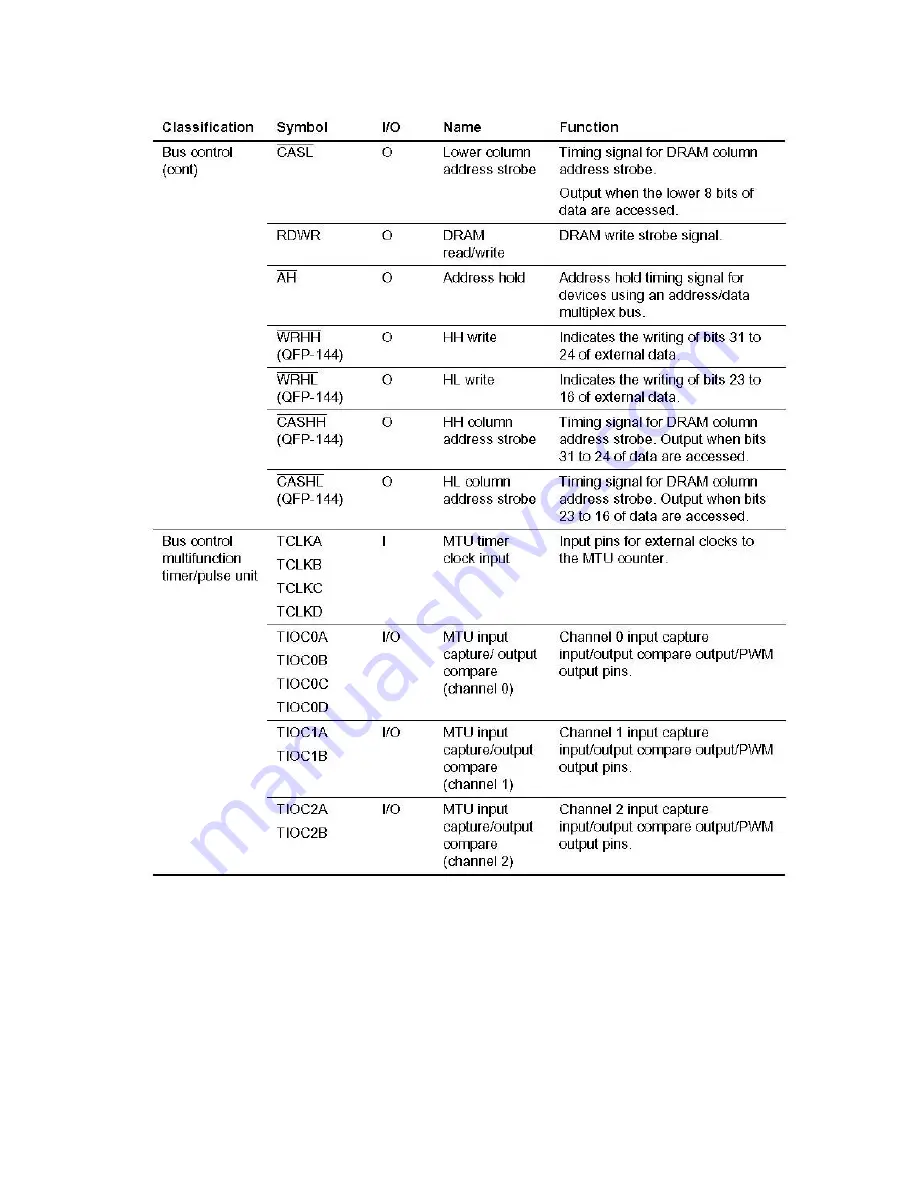

Page 15: ...TTP 245 TTP 343 11 2 2 1 MCU PIN Description ...

Page 16: ...TTP 245 TTP 343 12 ...

Page 17: ...TTP 245 TTP 343 13 ...

Page 18: ...TTP 245 TTP 343 14 ...

Page 19: ...TTP 245 TTP 343 15 ...

Page 22: ...TTP 245 TTP 343 18 2 5 Decoder Circuit Fig 2 5 Decode Circuit Diagram ...

Page 32: ...TTP 245 TTP 343 28 2 12 USB Circuit Fig 2 12 USB Circuit Diagram ...

Page 33: ...TTP 245 TTP 343 29 2 12 1 USB PIN Function The standard USB 1 1 PIN function is as following ...

Page 34: ...TTP 245 TTP 343 30 ...

Page 43: ...TTP 245 TTP 343 39 Bottom side of PCB JP6 Memory card connector JP4 U14 Cutter driver chip ...

Page 47: ...TTP 245 TTP 343 43 4 Replace the top inner cover 5 Reassemble in reverse procedures ...

Page 58: ...TTP 245 TTP 343 54 4 Reassemble parts in reverse procedures Screws Head Open Micro Switch ...

Page 60: ...TTP 245 TTP 343 56 Screws Ribbon Sensor Top inner cover ...

Page 90: ...TTP 245 TTP 343 86 9 1 Cover drawing ...

Page 92: ...TTP 245 TTP 343 88 9 2 Main Board drawing ...

Page 95: ...TTP 245 TTP 343 91 9 3 Top Inner Cover drawing ...

Page 97: ...TTP 245 TTP 343 93 9 4 Ribbon Mechanism Assembly drawing ...

Page 99: ...TTP 245 TTP 343 95 9 5 1 Lower Inner Cover drawing ...

Page 101: ...TTP 245 TTP 343 97 9 5 2 Lower Inner Cover drawing ...

Page 103: ...TTP 245 TTP 343 99 9 6 Stepping Motor Assembly drawing ...

Page 106: ...TTP 245 TTP 343 102 9 7 Option and accessories drawing ...