12

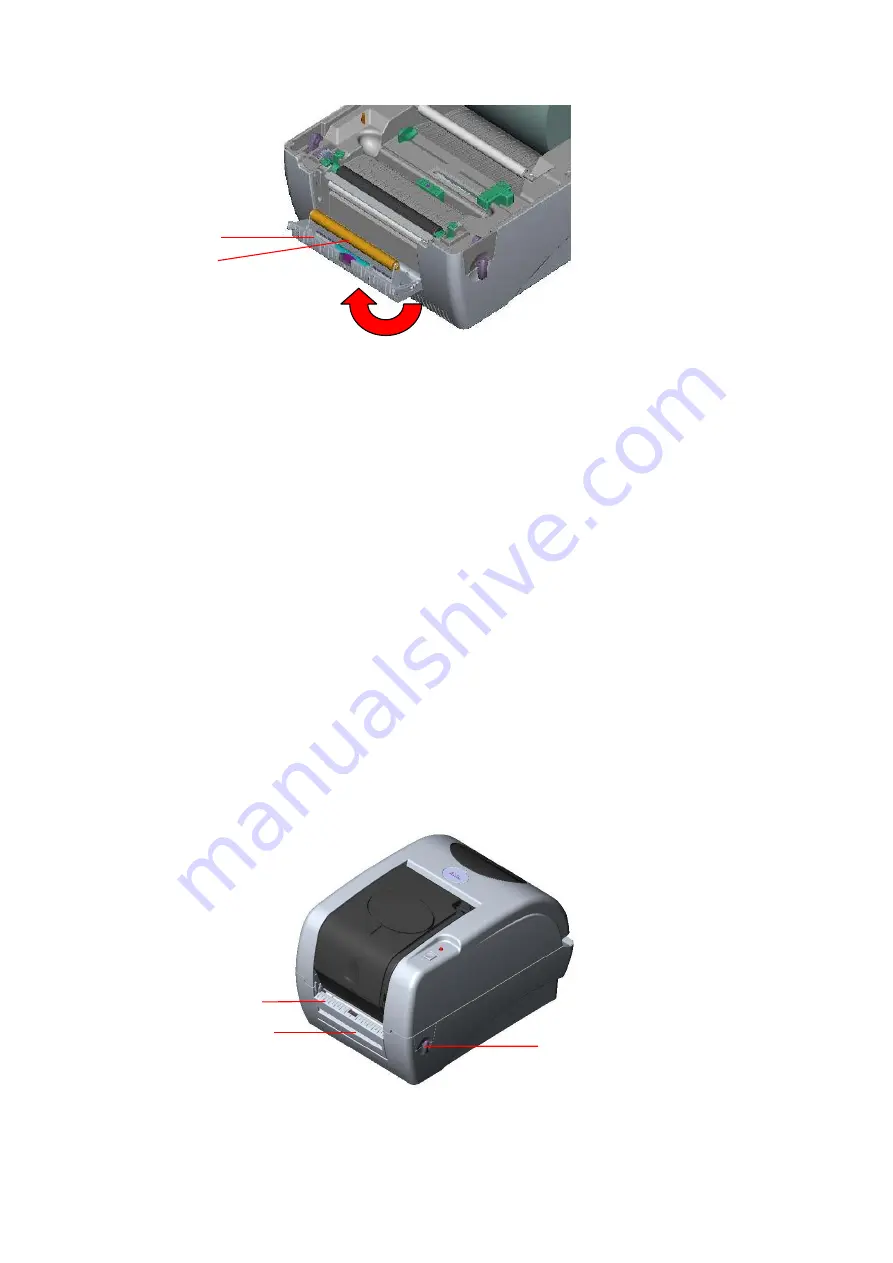

Fig. 17 Peel-off panel installation (II)

9. Lift up the peel-off panel to the lower cover to close it.

10. Use a screwdriver to screw down whole screws on the lower inner cover and the

lower cover.

11. Close the top cover by arranging the top cover support back to the flute

and push it forward then

close the

top

cover slowly.

3.5.1 Loading the Paper in Peel-off Mode

Note: Both thermal paper and plain paper apply for peel-off function but

neither PVC nor vynle work at peel-off function.

1.

Insert a 1” label spindle into a paper roll.

2.

Open the printer top cover by pulling the top cover open levers. The top cover

support will hold the printer top cover.

Fig. 18 Open the top cover

Peel-off

panel

Roller

Top Cover Open Lever

Peel-off panel

Backing paper

Opening