05/2004

TSCHAN

-TORMAX VSG

- 5 -

5 Assembly

5.1 Before assembly

•

Injury hazard!

•

Switch off the drive before commencing any work on the coupling!

•

Secure the drive against accidental activation and rotation!

•

Incorrectly tightened screws can lead to serious personal injury

and material damage!

•

Assemble outside of the danger zone. Ensure that suitable means

of transport are available and that transport routes are free of ob-

stacles.

•

In accordance with health and safety regulations, all rotating parts

must be protected against accidental contact and against falling

parts by fixed protective installations.

•

To avoid sparks, use stainless steel covers!

•

As a minimum requirement, the covers must comply with the IP2X

protective system.

•

The covers should be designed such that no dust can settle on the

coupling.

•

The cover may not contact the coupling and hinder its correct

functioning in any way.

Clean all coupling components before assembly. Do not use petrol, paraffin or oil to clean the

rubber element. The connecting surfaces of the flange must be clean, dry and free of grease.

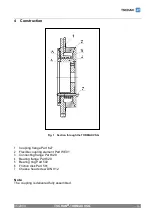

Place the coupling with the coupling flange (Figure 1, Item 1) in the centre of the flywheel on

the combustion engine. Take care that the components do not cant. Tighten the fastening

screws uniformly.

Connect the cardan shaft to the connecting flange (Figure 1, Item 3).