26

saue

Series 90

Fluid and Filter Maintenance

6

To ensure optimum service life of Series 90 products,

regular maintenance of the fluid and filter must be

performed. Contaminated fluid is the main cause of

unit failure. Care should be taken to maintain fluid

cleanliness while performing any service procedure.

Check the reservoir daily for proper fluid level, the

presence of water (noted by a cloudy to milky appear-

ance, or free water in bottom of reservoir), and rancid

fluid odor (indicating excessive heat). If either of

these conditions occur, change the fluid and filter

immediately.

It is recommended that the fluid and filter be

changed per the vehicle/machine manufacturer’s

recommendations or at the following intervals:

6. Fluid and Filter Maintenance

e

p

y

t

-

d

e

l

a

e

s

a

h

t

i

w

m

e

t

s

y

S

r

i

o

v

r

e

s

e

r

s

r

u

o

h

0

0

0

2

-

g

n

i

h

t

a

e

r

b

a

h

t

i

w

m

e

t

s

y

S

r

i

o

v

r

e

s

e

r

e

p

y

t

s

r

u

o

h

0

0

5

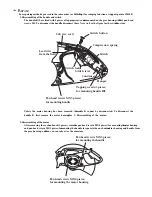

Charge pump

Filter

Hydraulic fluid reservoir

Adjustable

Charge pressure relief valve

To pump case

to low

pressure

side and

control

Mano-

Vacuummeter

To pump case

Charge pump

Hydraulic fluid reservoir

Filter

to low

pressure

side and

control

Screen

Adjustable

Charge pressure

relief valve

Suction Filtration Schematic

Charge Pressure Filtration Schematic

(Partial Flow)

P000797 E

P000798 E

It may be necessary to change the fluid more fre-

quently than the above intervals if the fluid becomes

contaminated with foreign matter (dirt, water, grease,

etc.) or if the fluid has been subjected to temperature

levels greater than the recommended maximum.

Never reuse fluid.

The filter should be changed whenever the fluid is

changed or whenever the filter indicator shows that it

is necessary to change the filter.

Filters can be in either pressure filtration or suction

filtration configurations. For suction filtration, filters

should have a Beta-ratio of

β

10

>2. For charge pres-

sure filtration, filters should have a Beta-ratio of

β

10

>10. See Sauer-Sundstrand publication BLN-9887

or 697581 and ATI-E 9201 for more information on

filtration.

CONTENTS

Summary of Contents for PTV100/72

Page 11: ......

Page 12: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 44: ......

Page 54: ...Contents iv 032015 PN 4 ...

Page 175: ...Troubleshooting 70 35 032015 PN 133 ...

Page 187: ...Troubleshooting 70 47 032015 PN 145 ...

Page 205: ...Warranty DX EMISSIONS EPA 19 12DEC12 2 2 TS1721 UN 15JUL13 90 6 032015 PN 163 ...

Page 213: ...Warranty DX EMISSIONS CARB 19 01AUG14 8 8 RG26036 UN 24JUN14 90 14 032015 PN 171 ...

Page 214: ...Warranty 90 15 032015 PN 172 ...

Page 220: ...Engine Registration IBC 2 032015 PN 178 ...

Page 223: ...Engine Registration IBC 5 032015 PN 181 ...

Page 224: ...Engine Registration IBC 6 032015 PN 182 ...

Page 225: ...SERVICE MANUAL ...

Page 262: ...saue Axial Piston Pumps and Motors Service Manual Series 90 CONTENTS ...

Page 348: ...saue 87 Series 90 Exploded View Parts Drawings 10 Notes CONTENTS ...

Page 350: ......

Page 351: ......

Page 352: ......

Page 353: ......

Page 354: ......

Page 355: ......

Page 356: ......

Page 357: ......

Page 358: ......

Page 359: ......

Page 360: ......

Page 361: ......

Page 362: ......

Page 363: ......

Page 364: ......

Page 365: ......

Page 366: ......

Page 367: ......

Page 368: ......

Page 369: ......

Page 370: ......

Page 371: ......

Page 372: ......

Page 373: ......

Page 374: ......

Page 375: ......

Page 376: ......

Page 377: ......

Page 378: ......

Page 379: ......

Page 380: ......

Page 381: ......

Page 382: ......

Page 383: ......

Page 384: ......

Page 385: ......

Page 386: ......

Page 387: ......

Page 388: ......

Page 389: ......

Page 390: ......

Page 391: ......

Page 392: ......

Page 393: ......

Page 394: ......

Page 395: ......

Page 396: ......

Page 397: ......

Page 438: ......

Page 439: ......

Page 440: ......

Page 441: ......