31

8.1 - ROUTINE MAINTENANCE

Keep the gear unit at its maximum efficiency by following the routine maintenance schedule.

Good maintenance ensures the unit’s maximum performance, extended service life and conti-

nued compliance with safety regulations.

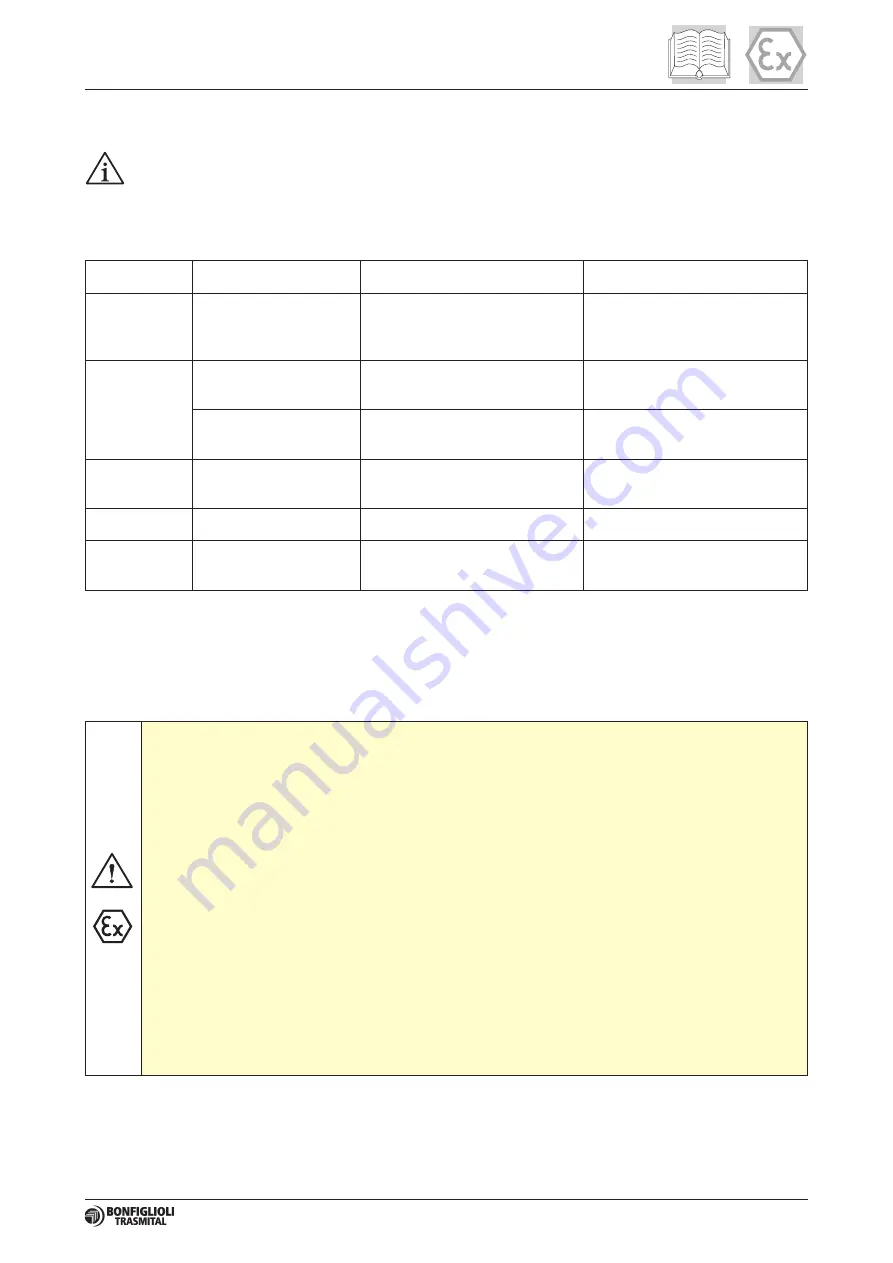

Frequency

Component

Type of check

Action

at start

Gear unit casing

Check that the external

temperature does not exceed

75-80 °C

Stop the machine and contact

Bonfiglioli Trasmital’s Technical

Service

after 200 hrs

Original consignment

lubricant

Replace

Replace with new lubricant

External fasteners

Check locking torque

Tighten down to specified

torque

1000 hrs

External seals and

gaskets

Check oil level

Check for leaks by eye

Service or replace components

as required

2500 hrs

Lubricant

Replace

Replace with new lubricant

5000 hrs

Gear unit seals and

gaskets

Inspect carefully for wear/age-

ing of external seals

Replace if aged/worn

For installations in zones 21 and 22 the User must schedule and implement a regular clea-

ning programme for all surfaces and recesses to avoid dust build-ups of more than 5 mm

in depth.

Every 1000 hrs. of operation or after 6 months

:

•

Measure the surface temperature at the coupling between the gear unit and motor, and at the

points which are most shielded from the motor’s cooling fan. The maximum temperature must

not be more than 75-80°C, nor may this value be exceeded during operation.

Every 5000 hrs. of operation

:

•

Change the synthetic oil and bearing grease if the gear unit is not life lubricated.

•

Replace all externally accessible seal rings unless this has already been done as a result of

problems occurring before the scheduled maintenance deadline.

(A3)

Summary of Contents for PTV100/72

Page 11: ......

Page 12: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 44: ......

Page 54: ...Contents iv 032015 PN 4 ...

Page 175: ...Troubleshooting 70 35 032015 PN 133 ...

Page 187: ...Troubleshooting 70 47 032015 PN 145 ...

Page 205: ...Warranty DX EMISSIONS EPA 19 12DEC12 2 2 TS1721 UN 15JUL13 90 6 032015 PN 163 ...

Page 213: ...Warranty DX EMISSIONS CARB 19 01AUG14 8 8 RG26036 UN 24JUN14 90 14 032015 PN 171 ...

Page 214: ...Warranty 90 15 032015 PN 172 ...

Page 220: ...Engine Registration IBC 2 032015 PN 178 ...

Page 223: ...Engine Registration IBC 5 032015 PN 181 ...

Page 224: ...Engine Registration IBC 6 032015 PN 182 ...

Page 225: ...SERVICE MANUAL ...

Page 262: ...saue Axial Piston Pumps and Motors Service Manual Series 90 CONTENTS ...

Page 348: ...saue 87 Series 90 Exploded View Parts Drawings 10 Notes CONTENTS ...

Page 350: ......

Page 351: ......

Page 352: ......

Page 353: ......

Page 354: ......

Page 355: ......

Page 356: ......

Page 357: ......

Page 358: ......

Page 359: ......

Page 360: ......

Page 361: ......

Page 362: ......

Page 363: ......

Page 364: ......

Page 365: ......

Page 366: ......

Page 367: ......

Page 368: ......

Page 369: ......

Page 370: ......

Page 371: ......

Page 372: ......

Page 373: ......

Page 374: ......

Page 375: ......

Page 376: ......

Page 377: ......

Page 378: ......

Page 379: ......

Page 380: ......

Page 381: ......

Page 382: ......

Page 383: ......

Page 384: ......

Page 385: ......

Page 386: ......

Page 387: ......

Page 388: ......

Page 389: ......

Page 390: ......

Page 391: ......

Page 392: ......

Page 393: ......

Page 394: ......

Page 395: ......

Page 396: ......

Page 397: ......

Page 438: ......

Page 439: ......

Page 440: ......

Page 441: ......