1.

Inspect the machine daily for potential fire hazards and make any necessary repairs up

immediately.

2.

Always ensure that excess grease and oil accumulation, including spillage, are cleaned up

immediately.

3.

Use only nonflammable cleaning agents for cleaning the machine or any machine

component.

4.

Store oily rags and other combustible materials in a fireproof location.

5.

Before performing repair work such as welding, the area surrounding the repair location

should be cleaned and a fire extinguisher positioned close by.

6.

Maintain a charged fire extinguisher on or near the machine at all times and know how to use

it.

Inspections

Periodic inspection of the unit according to a regular schedule will establish the normal state of

the unit for personnel associated with its operation and maintenance and provide a set of

consistent conditions, which will tend to highlight any occurrence of a potentially hazardous

malfunction.

On a daily basis walk around the unit and look closely for any indication of the following:

1.

Loose threaded connections.

2.

Metal fatigue or excessive corrosion.

3.

Abraded hose surfaces.

4.

Hydraulic fluid leakage.

5.

Possible obstruction of moving parts – especially in the drive train.

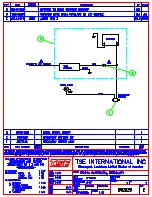

To ensure proper operation and long life of your TSE International products, use only good quality

lubricants and maintain a regular maintenance schedule as recommended by TSE International

and our component suppliers.

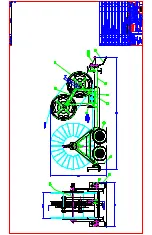

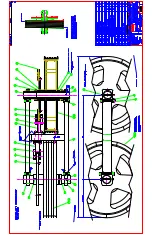

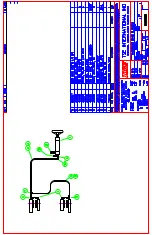

Prior to start-up of new TSE International products, all fluid levels are to be checked to ensure

correct operating levels. All lubrication and maintenance points are to be inspected and

lubricated as illustrated on the Lubrication and Maintenance Instructions sheet.

While TSE International recommends specific intervals, they are intended as a minimum general

guide for the maintenance of the equipment. Some job conditions and/or locations may dictate

more frequent service intervals than have been recommended.

Summary of Contents for T50 BWRC

Page 11: ......

Page 12: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 43: ...www dexteraxle com OPERATION MAINTENANCE SERVICE MANUAL 600 8 000 lb Axles Related Components ...

Page 125: ...Service Record Date Service Performed Mileage ...

Page 126: ...Service Record Date Service Performed Mileage ...

Page 127: ...Service Record Date Service Performed Mileage ...