2

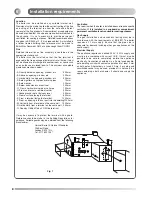

These instructions are suitable for the following boilers :

Calydra comfort 80

Calydra comfort 100

Do not forget the Logbook!

Chaffoteaux & Maury supports Benchmark, the heating industry code to ensure the correct installation, commissioning and

servicing of domestic central heating systems.

To The Householder

Make sure you have a completed Logbook for your boiler.

This provides a record of the commissionning of your boiler. It

contains important information about your particular installation that may be required by service engineers. The logbook will

also provide contact details for the installer should you need guidance in the use of this appliance or if there are any problems.

As with your car, your boiler will work more reliably and efficiently if regularly serviced. We recommend an annual service

check. The service history of the appliance will be recorded on the logbook.

In the unlikely event of any problems with your boiler or system you should first contact your installer. If your installer cannot

resolve the problem he should telephone our national service helpline.

A charge may be made if Chaffoteaux & Maury Service is called out to resolve a non-product related fault.

Your statutory rights are not affected.

TO CONTACT C&M SERVICE, PLEASE CALL THE NATIONAL WARRANTY HELPLINE ON:

0 870 243 0224

To The Installer

As part of the commissioning of this appliance it is vital that the Logbook is completed and given to the Householder. Please

ensure that your customer is aware of the importance of keeping the Logbook safe as a record of the installation and the

appliance service history.

Please ensure that your customer is aware of the correct operation of the system, boiler and controls.

CUSTOMER CARE

Chaffoteaux & Maury Ltd., as a leading manufacturer of domestic and commercial water heating appliances is committed to

providing high quality products and a high quality after sales service. If it is necessary to contact an engineer, then telephone

the national warrenty helpline 0870 243 0224.

Advice on installation or servicing can also be obtained by contacting the Chaffoteaux Customer Services Department at

Telford.

CUSTOMER SERVICES DEPARTMENT

Tel: 01952 222288

Fax: 01952 260915

GUARANTEE

The manufacturer`s guarantee is for 12 months from the date of purchase. The guarantee is invalidated if the appliance is not

installed in accordance with the recommendations made herein or in a manner not approved by the manufacturer. To assist us

in providing you with an efficient after sales service, please return the guarantee registration card enclosed with the boiler

without delay.

STATUTORY REQUIREMENTS

The installation of this appliance must be carried out by a CORGI Registered person or other competent person and in

accordance with the requirements of the Gas Safety (Installation and Use) Regulations.

In addition, the installation must also comply with the current byelaws of Local Water Undertakings, Building Regulations, IEE

Wiring Regulations, Local Authority Building Standards (Scotland) Regulations and the Safety Document 635 The Electricity at

work Regulation. The appliance named below does not contain any asbestos or asbestos products, or mercury derivatives.

Additional CFC’s have not been used in this product.

The appliance does not contain any potential hazard in relation to the COSHH regulations.

It should also be carried out in accordance with current editions of the following British Standards Codes of practice: BS 6891,

BS 5440 parts 1 and 2, BS 5449 part 1, BS 7593, BS 6798, BS 5546, BS 4814, BS 7074 part 1 and 2, BS 7671 and BG DM2.

If there is a possibility of the incoming mains water pressure exceeding 10 bar then a suitable pressure limiting valve must be

fitted where pressures exced 6 bars a pressure limiting is preferred.

Precautions:

During servicing, keep the dust generation to a minimum and avoid inhaling any dust and contact with the skin

and eyes. Normal handling and use will not present any discomfort, although some people with a history of skin complaints

may be susceptible to irritation. When disposing of the ceramic lining, ensure that it is securely wrapped and wash hands after

contact.

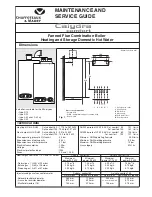

Summary of Contents for Calydra Comfort 100 Nat

Page 48: ...110...