5

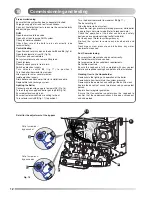

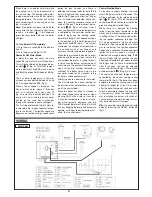

Adjustment on the PCB :

- P3 : potentiometer TAC (Temporisation Anti Cycle)

may now be adjusted between 30 seconds and 3

minutes (see detail) (factory set at 3 minutes).

- JP3 : the spade connector allows the gas rate to be

reduced to 1/3 performance by positionning

spade across pins as shown

A

Full performance across pins as shown

B.(factory

set)

After completling adjustments replace rubber cover and

refit outer casing

ADJUSTMENTS ON CONTROL PCB

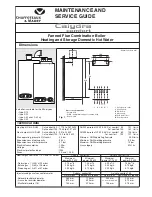

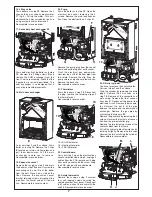

ROUTINE SERVICING

To ensure continued efficient operation of

the appliance, it is recommended that it is

checked and serviced as necessary at

regular intervals. The frequency of servic-

ing will depend upon the particular instal-

lation condition and usage, but in general,

once a year should be adequate.

It is the law that any service work must be

carried out by a competent person such

as your local Chaffoteaux Service Centre,

British Gas or other CORGI registered

personnel in accordance with the current

Gas Safety (Installation and Use)

Regulations.

The service schedule should include

the following operations:

- Check the pressure in the system.

- Check the correct operation of the

appliance.

- Check the correct operation of the gas

controls.

- Check the functions of the safety con-

trols.

- Check combustion chamber insulation

panels for damage.

- Clean the burner.

- Clean the heat exchanger.

- Check the burner manifold injectors.

- Clean gas and water filters.

- Check expansion vessel charge pres-

sure.

- Clean and check operation of safety

valve.

Additional Procedures that may be

necessary:

- Check burner pressure and gas flow

rates.

- Check that the fan blades are clean.

- Check, clean and replace components as

necessary.

- Carry out combustion test utilising the test

points in the flue turret.

SUGGESTED SEQUENCE for SERVIC-

ING

Before disconnecting or removing any

parts, isolate the gas and electricity sup-

plies. Ensure that the appliance is cool.

(for detail please see section on Parts

Removal and Replacement)

Preliminary Checks

- Remove outer case

- Check the system pressure is at least

0.8 bar cold

- Check operation of solenoids.

- Check that the burner is extinguished fully

when solenoids are closed in both DHW

and C/H modes.

- Test ionisation functions and check that

lockout occurs by turning off gas tap.

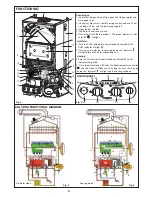

Temperature regulation for both C/H and

DHW circuits are controlled by 2 thermis-

tors. The C/H knob allows the adjustment

of temperature between 35 and 85°C. The

DHW temperature is limited to 60°C. DHW

and C/H thermistors are identical and

interchangeable.

Resistance value are

-5000

Ω

at 25

°C

-2631

Ω

at

40°C

-620

Ω

at

80°C

-255

Ω

at

110°C

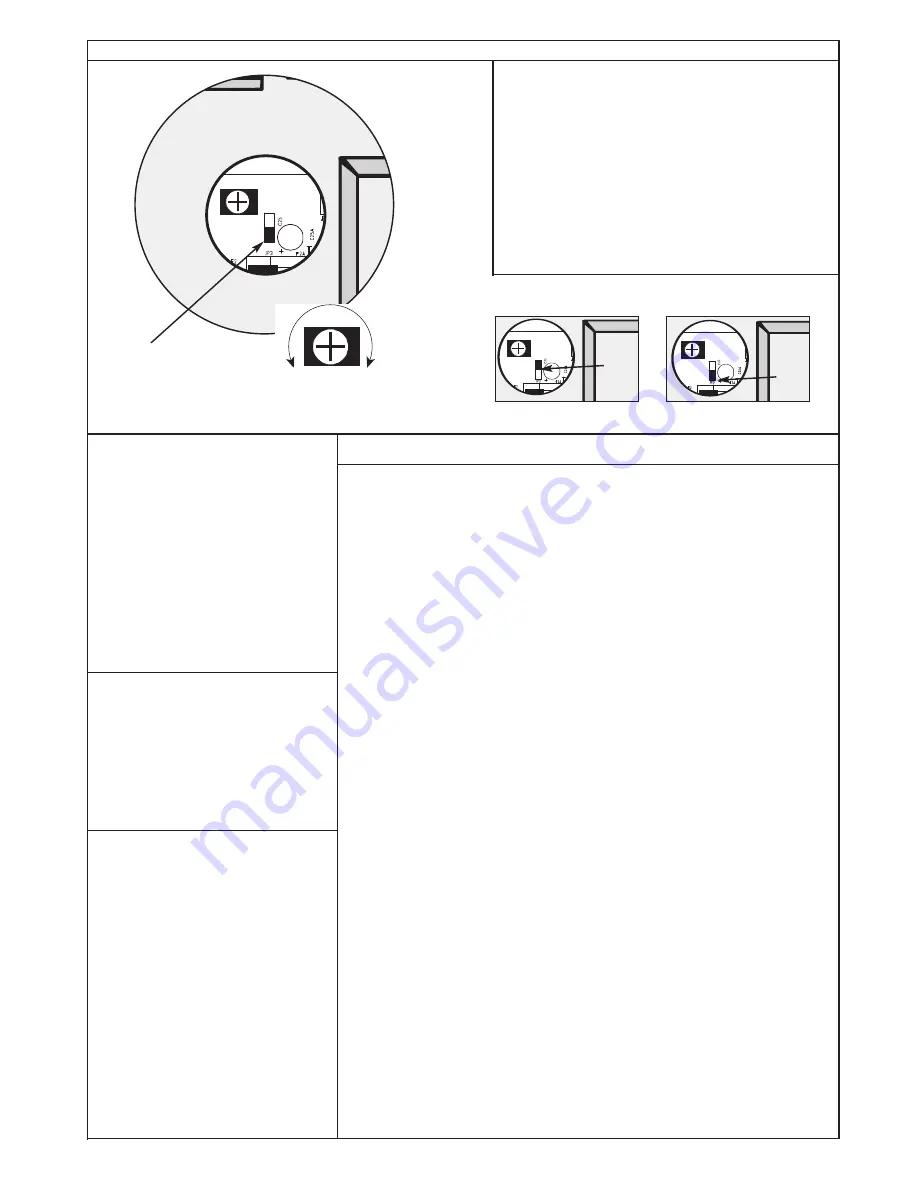

REGULATION

The air flow rate is detected by a pressure

differential created by a venturi located in

the flue duct.

ON threshold

∆

P > 130 Pa

OFF threshold

∆

P < 100 Pa

AIR PRESSURE SWITCH

C

10

C

10

C

11

C

11

C

38

C

38

F1

F1

F1A

F1A

J1J1

J2J2

J5 J5

MV1 MV

1

R67

R67

R72

R72

R73

R73

R

75

R

75

R

76

R

76

R85

R85

1

2

H

O

R

N

L

T

H

E

R

M

O

S

T

A

T

N

L

J

9

J

1

0

J

1

1

T

A

2

4

V

2

3

0

V

P3

(P3-P4-P5)

mini

maxi

Detail

P3

P3

1/3

3/3

P3

P3

1/3

3/3

P3

JP3

A

B

Summary of Contents for Calydra Comfort 100 Nat

Page 48: ...110...