18

(4) Motor

■

General precautions

1. Perform the wiring work according to the electric equipment technical standard and the regulations of

the electric power company. Take care that the voltage drop is not large, since the longer the wiring

distance becomes, the more the voltage drop will increase. Generally, you should use electric wire that

has proper thickness and length that will not cause the voltage to drop 2% or more. Voltage drop may

prevent brake release. Use a power supply which is described on the nameplate.

2. Refer to the Table 2 below for the applicable cable diameter. Using cables with smaller diameter will

render the waterproof feature ineffective.

3. After wiring is completed, check the mounting set screws and connector whether they are not loose.

4.

Grounding

After installation of the Linipower Jack, ground the motor (Earth work in class 3 or higher).

Table 2. (Motor terminal box)

Motor capacity

Connector

configuration

Applicable cable

diameter

Connector

mounting part

Size of ground

terminal

0.2 to 0.4 kW

SK-14L

φ

11 to

φ

13

G1 / 2

M4

0.75 to 1.5 kW

A20c

φ

14 to

φ

15

G3 /4

M4

2.2 to 2.3 kW

A25c

φ

19 to

φ

20

G1

M4

※

Connector connection will be required depending on lead-out part size of the terminal box or when servo

motor is used. Please refer to the drawing when using a special type motor.

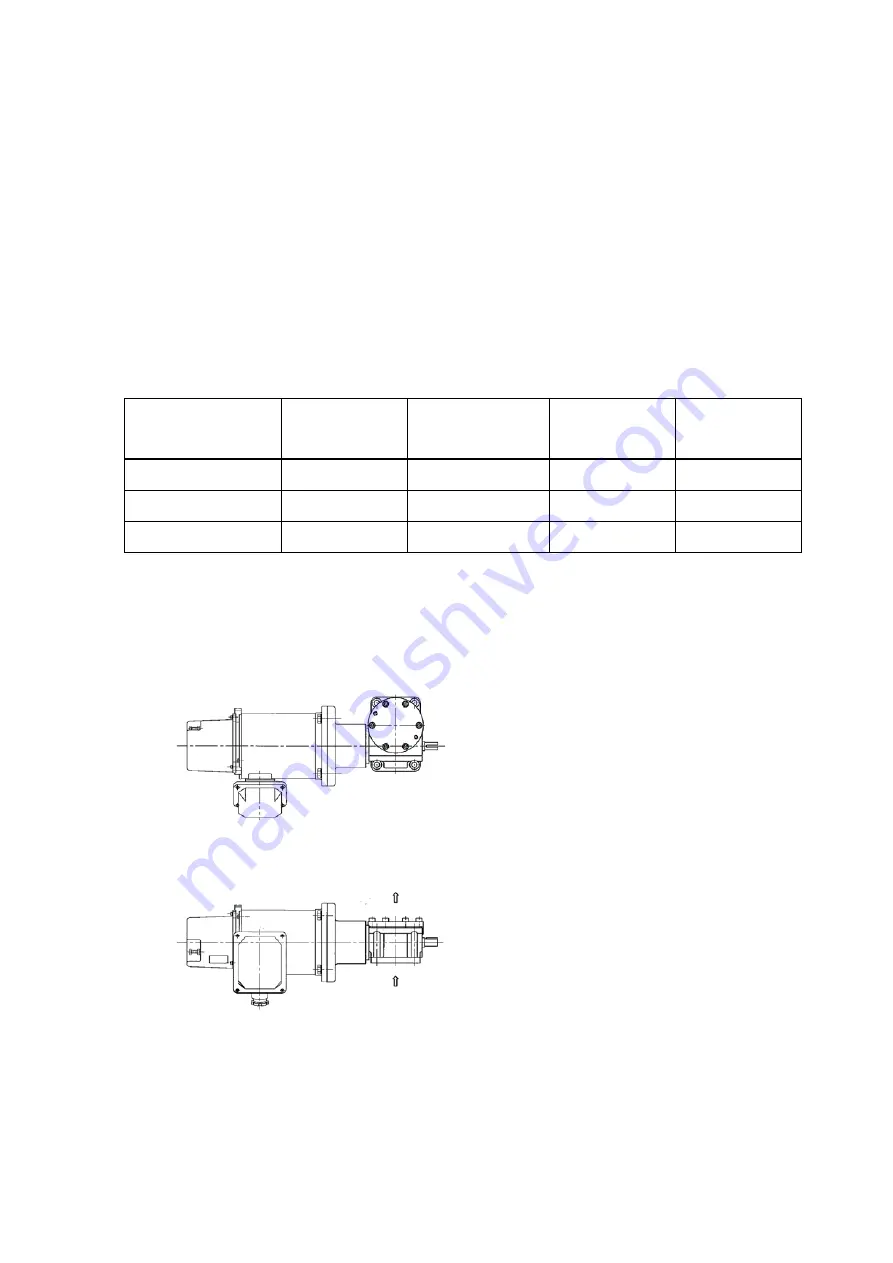

∎

Motor connection

The screw shaft of the standard type and rotation

prevention type move in the direction of the

arrows shown in the picture on the left with

normal wiring. The traveling nut moves in the

same direction as the travel screw.

Note: Add necessary protective devices to each

contact site.

Note: Please comply with the regulations of

electric companies for switches and fuse.

★

★