6

Frame No.

Amount of grease

Initial enclosed quantity

screw shaft

(

amount per 100mm stroke

)

Reducer unit

002

5 g

35 g

005

5 g

35 g

010

5 g

80 g

025

10

–

15 g

170 g

050

10

–

15 g

370 g

100

20

–

30 g

470 g

150

20

–

30 g

700 g

200

40

–

50 g

830 g

300

40

–

50 g

2600 g

500

50

–

100 g

5500 g

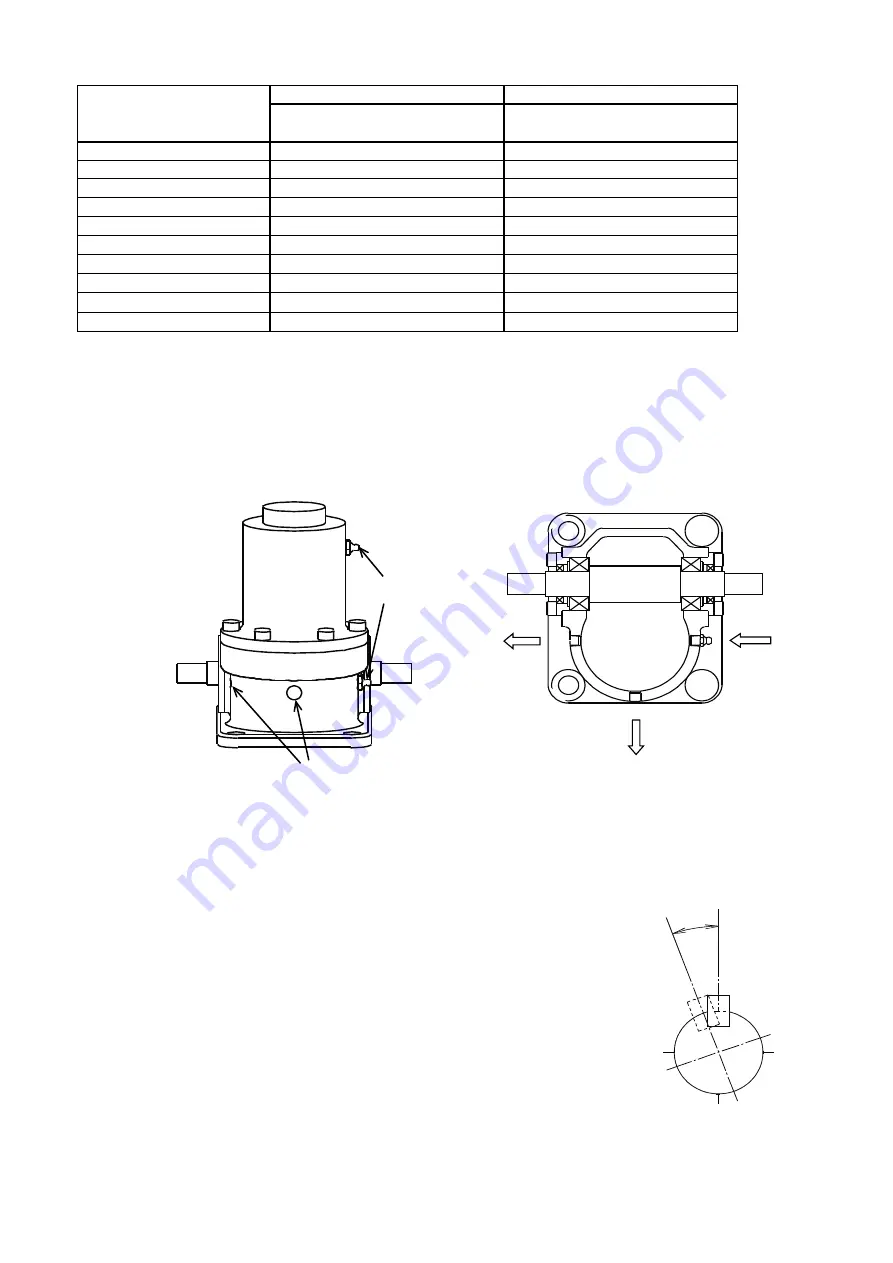

3 Reducer units JWM025/JWB025/JWH025 and above are provided with grease nipples and hex socket

plugs. Remove the plugs and pour grease through the nipples until it seeps from the openings. Then

firmly seal the openings with tape.

4

Grease upper bearings for JWB (Ball Screw Type) and JWH (High Lead Ball Screw Type) using the

grease nipple set attached to their housings, at 6-month intervals.

Not necessary for jacks JWB010/JWH010 and below.

※

In case of the made-to order type, confirm with the final drawing, grease nipple might not be same

as above.

4 Inspect regularly for general backlash and screw unit condition.

Jack life and replacement timing are determined by the following:

• JWM

--- Backlash in the direction of screw shaft and nut

hits 1/4 of the screw pitch.

• JWB/JWH

--- Visible particles due to wear and tear of the screw unit

• ALL types

--- Check for backlash between the worm and worm gear.

Backlash excess of 30

˚

for H speed and 60

˚

for L speed

indicates the need to replace the worm and worm gear.

(Angle C in Fig.6)

Generally, continuous use without lubrication at recommended

intervals may cause inefficiency of shaft and failure of travel nut.

Pouring grease

Grease

Grease

Grease nipple

Hex plug

Fig.4. Grease nipple

Fig. 5. Greasing method

Table 5. Amount of Grease

Fig.6. Input backlash

C

★