MODEL

442A

TSURUGA ELECTRIC CORPORATION

3

min120

Y

15mm

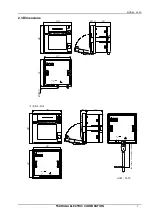

2. Installation

2.1 Main body

Insert a main body to front side of panel, and fix it with

screws at both side from back.

Panel cutout : 92

+0.8

0

× 92

+0.8

0

mm

Panel thickness: 1 to 6 mm

Note)1.5mm or more thickness is

recommended in case of aluminum

panel.

Tightening torque: 0.2 to 0.3N

・

m

Installation pitch between two products.

Installation pitch (Lengthwise direction, Y):

120mm for 442A

200mm for 442A-E2

CAUTION

Do not tight too much a screw that might damage housing.

Use fan, etc, for forced draft in case of installing more than 2

products.

2.2 Roll chart

WARNNING

Do not touch thermal head and its around after printing, where

high temperature is supposed.

Replace roll chart or clean head after the temperature of head falls.

CAUTION

Do not insert fingers or alien substances into printer. Printer

cutter might injure fingers etc.

Do not open a roll chart cover by pressing Open/Close button

while printing.

Do not press Open/Close button while holding a roll chart cover

down.

Do not pull up roll paper while closing a roll chart cover.

Give full attention not to insert fingers when closing a roll chart

cover.

Do not insert alien substances to driving gear when closing a roll

chart cover.

R E A R