-5-

CAUTION

• To supply voltage variation within ±10% of the rated voltage.

• The water temperature for operating the pump should be between 0 ~ 40℃.

Failure to observe the precautions given above could cause the pump to

malfunction, which may lead to current leakage or electrical shock.

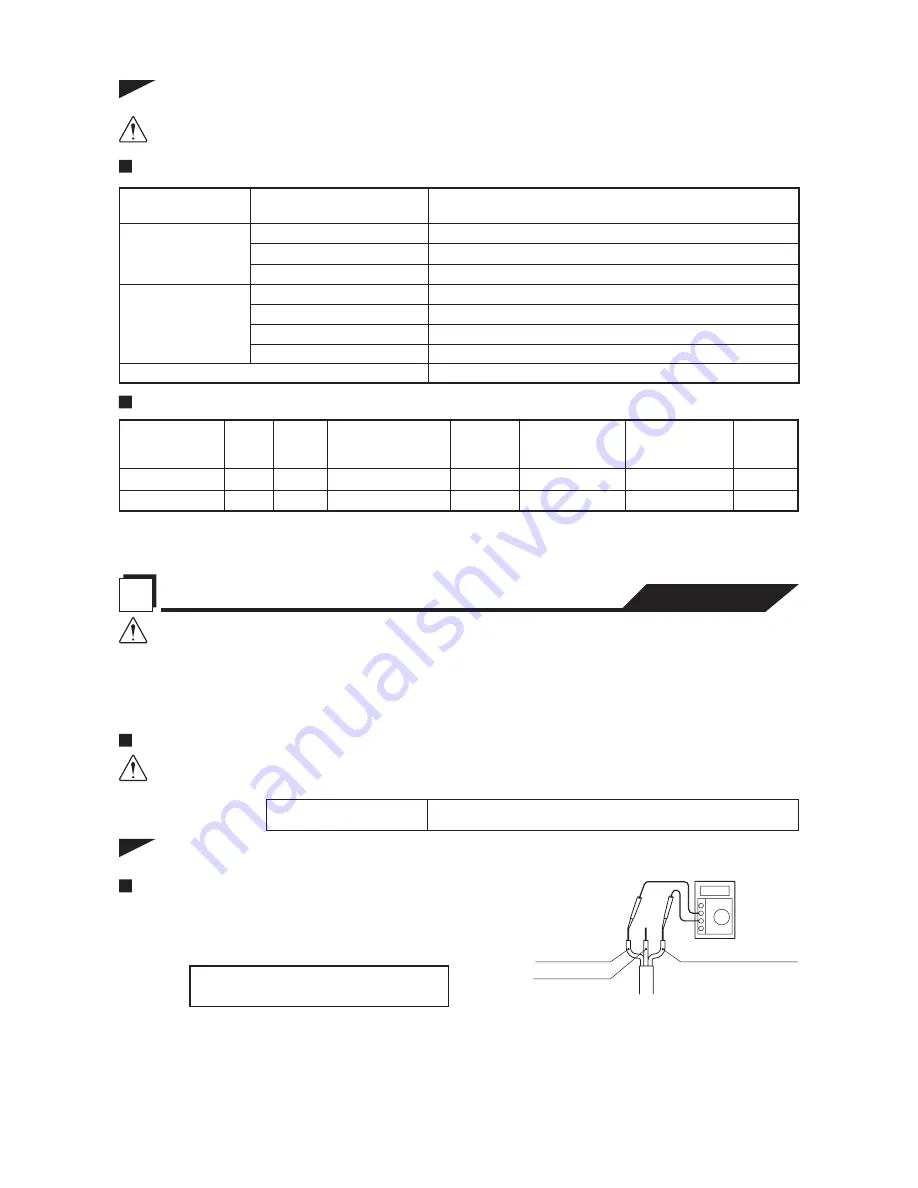

Critical Use Pressure

CAUTION

Do not operate the pump in an area that is exposed to a water pressure that

exceeds the values given below.

Preparation for Installation

Insulation resistance reference value

= 20M Ω minimum

Note:

The insulation resistance reference value of 20M Ω minimum is based on a new or repaired

pump. For reference values of a pump that has already been put into operation, refer to "7.

Maintenance and Inspection" of this manual.

Note:

To use the pump for a special solution, contact the dealer where it was purchased, or the

Tsurumi sales office in your area.

Single-phase power supply:

Use a megger to measure the resistance between

each core of the cabtyre cable and the (green)

ground wire to verify the insulation resistance of

the motor.

Note:

The weight (mass) given above is the operating weight of the pump itself, not including the

cabtyre cable.

Standard specifications (50/60Hz)

Bore

mm

Model

Output

kW

Phase

Max.capacity

m

3

/min

GPM

Starting

Method

WHT

kg

50(80)

LB-1500

1.5

1

Capacitor-Start

32.5

Max.Head

m

ft.

17.5/21

57.4/68.9

0.42/0.42

111.0/111.0

50(80)

LBT-1500

1.5

3

Direct-on-Line

31.5

17.5/21

57.4/68.9

0.42/0.42

111.0/111.0

CAUTION

Do not operate this product under any conditions other than those that have

been specified.

Major Standard Specifications

Product Specifications

Applicable Liquids Consistency and

Temperature

Water, Rain Water, Font Water, Sand carring Water,

Ground Water ; 0 ~ 40℃

Pump

Impeller

Semi-Open Type

Shaft Seal

Double Mechanical Seal

Bearing

Shielded Ball Bearing

Specifications

Dry Submersible Induction Motor, 2-Pole

Insulation

Class B (1-phase) Class E (3-phase)

Protection System (built-in) Circle thermal protector

Turbine oil VG32 (non-additive)

Lubricant

Connection

Hose Coupling

Motor

L1-Red(Brown)

G-Green(Green/Yellow)

L2-White(Blue)

MΩ

L1 L2 G

Single-Phase

0.3MPa (3kgf/cm

2

) - discharge pressure during use

Critical Use Pressure

4 INSTALLATION