-10-

Operation

• The pump may become very hot during operation. Be careful not to contact

the pump accidentally to avoid being burned.

• To avoid serious injury, do not insert a finger or any other object in the

pump inlet holes.

• When the pump is not used for an extended period, be sure to turn off the

power (circuit breaker, etc.). Deterioration of the insulation may lead to

electrical leakage, electrical shock, or fire.

• In case of a power outage, turn off the power to the pump to avoid having it

start unexpectedly when the power is restored, presenting serious danger

to people in the vicinity.

Pay careful attention to the water level while the pump is operating. Dry operation may cause the pump to

malfunction.

See below,"Operating water level" for the water level necessary for operation.

WARNING

Note:

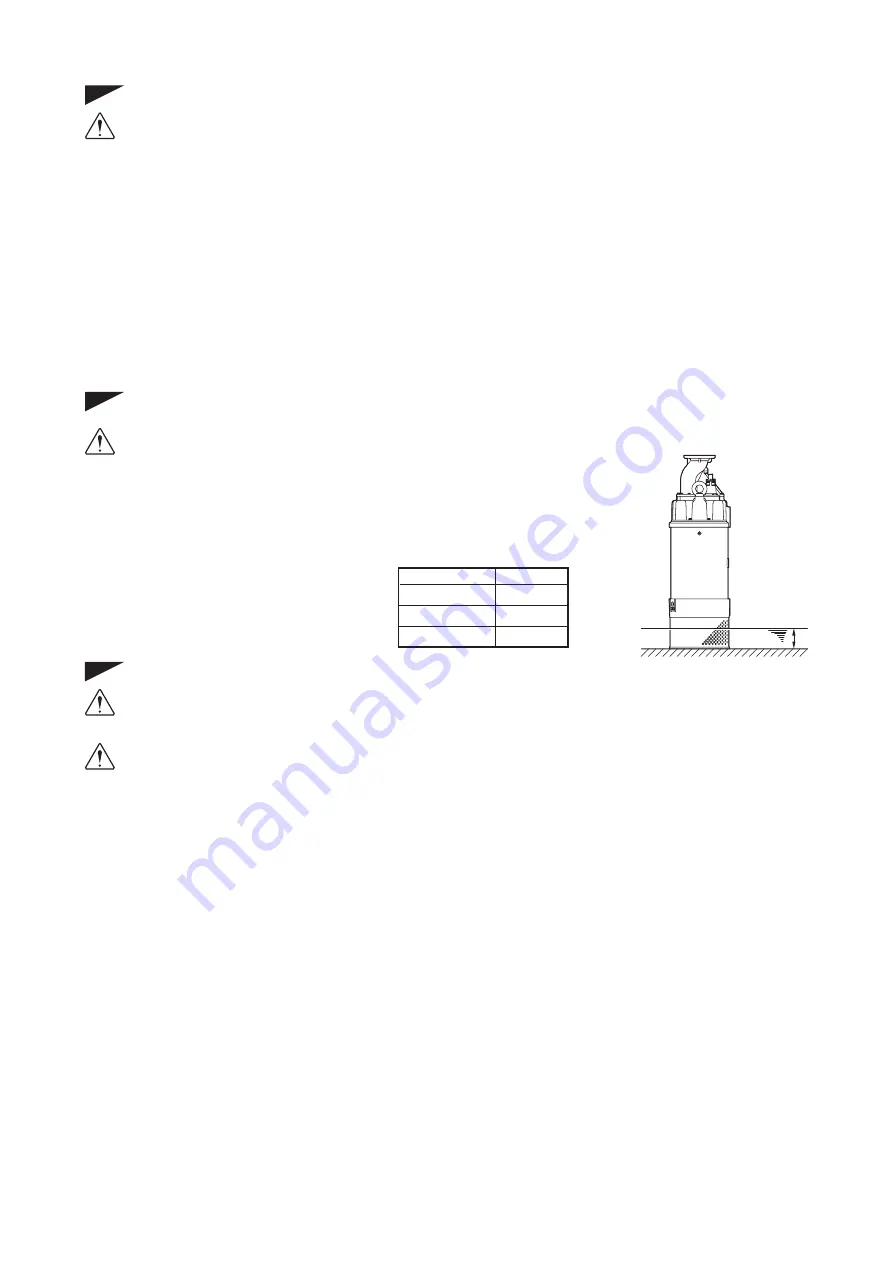

Operation water level

Do not operate the pump below the C.W.L.

(Continuous Running Water Level). Failure to

observe this condition may result in damage to the

pump, electrical leakage or electrical shock.

CAUTION

Motor protection system

During inspections or repairs, always be sure to turn off the power. Sudden

unexpected starting of the pump can cause electrical shock, shorting, or

serious injury.

• Always determine the cause of the problem and resolve it before resuming

operation. Simply repeating cycles of stopping and restarting will end up

damaging the pump.

• Do not continue operation at very low water level, or while the strainer

stand is clogged with debris. Not only will performance sufffer, but such

conditions may cause noise, heavy vibration, and malfunctioning.

1. Miniature Protector

This protector is embedded inside the motor coil. If the coil should overheat for any reason, bending of

the bimetal of the miniature protector triggers a signal, which in turn causes an extermal circuit in the

starting console or control panel to shut off the motor current. When the temperature returns to normal,

the protector is automatically reset, but restarting is controlled from the starting console or control panel.

A b-contact miniature protector is adopted, which is normally "closed" and goes to "open" upon overheating.

To protect the motor from current surges, be sure to install a motor breaker, thermal relay or similar device

in the external starting console or control panel. A 3E relay is able to protect the motor from overload, open-

phase or reverse-phase operation.

2.Water Leak Sensor

Models with output of 110kW have a water leak sensor electrode in the oil compartment.

If water leaks into the oil chamber due to wear of the mechanical seal, the water leak probe sends

a signal to the dedicated circuit (prepared by the user) in the external starting panel or control panel

and triggers a display, warning, and stops the pump to prevent the water from leaking into the motor.

Use a f oatless swich as the signal amplif er. To prevent the protector from operating due to an induced

current, the external starting console or control panel should be conf gured to swich off the motor only after

the leak sensor signal continues for several seconds.

WARNING

CAUTION

Note:

Note:

The table shows the C.W.L. for different output classes. Be careful not to allow

the water level to drop below the applicable limit.

200mm

Model

C.W.L.

LH6110

200mm

380mm

LH4110W

LH8110

C.W.L.