-11-

Regular maintenance and inspections are a necessity for continued efficient functioning of the pump. If

any abnormal conditions are noticed, refer to the section on Troubleshooting(p.18) and take corrective

measures immediately. It is recommended that a spare pump be kept ready in case of any problems.

Prior to inspection

Detach the cabtyre cable from the receptacle or terminals, after making

certain the power supply (circuit breaker, etc.) is turned off. Failure to follow

this precaution may result in a serious accident from electrical shock or

unexpected starting of the pump motor.

(1) Washing the pump

Remove accumulated matter from the surface of the pump and wash it with clean water. Take special

care to remove any debris from the impeller.

(2) Inspecting the pump exterior

Look for any peeling or chipped paint, and make sure the nuts and bolts are fastened tightly. Any cracks

in the surface should be repaired by cleaning that area, drying it and then applying a touchup coating.

Touchup is not supplied. Note that some kinds of damage or looseness may require that the unit be

disassembled for repairs. Please consult with your nearest dealer or Tsurumi representative.

WARNING

Note:

Regular Inspection

7 MAINTENANCE AND INSPECTION

Storage

When the pump is out of use for an extended period, wash it and dry it thoroughly, then store it indoors.

Always run a test operation before putting the pump back into service.

When the pump is left installed in water, it should be run at regular intervals (about once a week).

Note:

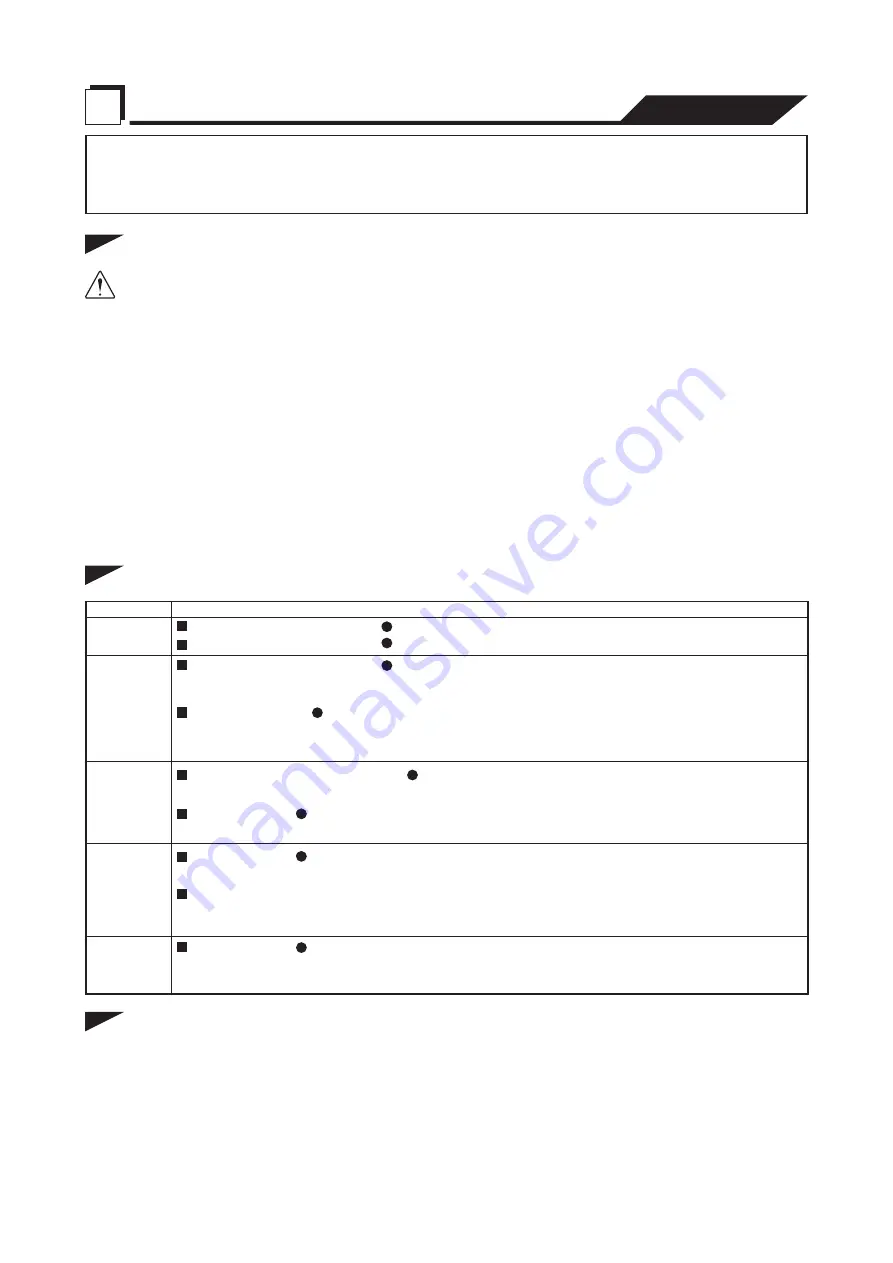

Interval

Monthly

EveryDay

Yearly

Inspection Item

Every

2 to 5 years

Measure operating current

Measure insulation resistance

Note: If the insulation resistance has become notably lower than the precious inspection, an

inspection of the motor will be necessary.

Note: Specialized know-how is required for inspecting and replacing the mechanical seal.

Consult with your nearest dealer or Tsurumi representative.

Note: Refer to details of oil inspection and oil change (p.12)

Note: Refer to details of oil inspection and oil change (p.12)

Note: Consult with your nearest dealer or Tsurumi representative regarding overhauls.

Overhaul

Change oil

Change mechanical seal

Change the oil every 12 months or after 6,000 hours of use, whichever comes first.

Oil inspection

Check the oil every 6 months or after 3,000 hours of use, whichever comes first.

Pump inspection

Power supply voltage tolerance (within ±5% of the rated voltage)

Measure power voltage

To be below the rated current.

Reference insulation resistance = 1MΩ or greater

This should be carried out even if there are no problems with the pump.

The frequency depends on how continuously the pump is in use.

A noticeable drop in performance may indicate wear in the impeller,etc., or else

clogging of the strainer stand, etc. Remove the clogged debris, and replace any

worn parts.

Half-yearly

Inspection of lifting chain or rope

Replace if damage, corrosion, or wear has occurred to the chain

or the rope. Remove if foreign object is attaching to it.