-13-

LH6110/8110 Disassembly

Before disassembly, drain the oil from the pump.

(1) Remove the strainer stand.

Remove the hex. nuts at the bottom of pump, then remove the strainer stand from the pump.

(2) Remove the lower pump casing.

Remove the hex. nuts and spring washers, then remove the lower pump casing from the pump.

(3) Remove the impeller.

With a box spanner or other tool, remove the hex. double nuts and plain washers, then remove the

impeller, impeller adjusting washer and lower shaft sleeve from the shaft.

(4) Remove the upper pump casing.

Remove the hex. nuts and spring washers to remove the upper pump casing.

(5) The upper shaft sleeve can be removed easily once the upper pump casing is removed.

(6) When absolutely necessary, the mechanical seal can be removed by first removing the oil casing.

See also the manual that comes with the replacement mechanical seal.

Note:

Note:

• Before disassembling the pump, first detach the cabtyre cable from the receptacle or terminals,

after making certain the power supply (circuit breaker, etc.) is turned off. To avoid electrical

shock, do not work with wet hands. Never check the operation of any parts (impeller rotation,

etc.) by turning on the power while the unit is partially assembled. Failure to observe these

precautions may result in serious accident.

• Do not disassemble or repair any parts other than those designated here. If repairs are

necessary in any other than the designated parts, consult with your nearest dealer or Tsurumi

representative. Improper repairs can result in electrical leakage, electrical shock, fire, or water

leaks.

• After reassembly, always perform a test operation before resuming use of the pump. Improper

assembly will cause the pump to malfunction, resulting in electrical shock or water leaks.

The procedure for disassembly and reassembly is shown here to the extent necessary for impeller

replacement. A specialized environment and facilites are necessary for work on the mechanical seal

and the motor parts. Contact your nearest dealer or Tsurumi representative in the event such repairs are

necessary.

WARNING

8 DISASSEMBLY AND REASSEMBLY

Remove the hex. bolts and spring washers, then detach the oil casing from the pump, being careful not to

damage the sliding surface of the mechanical seal. Remove the mechanical seal on the rotating end from the

shaft, then remove the mechanical seal on the upper fixed end.

A worn impeller can have sharp edges; be careful to avoid injury.

CAUTION

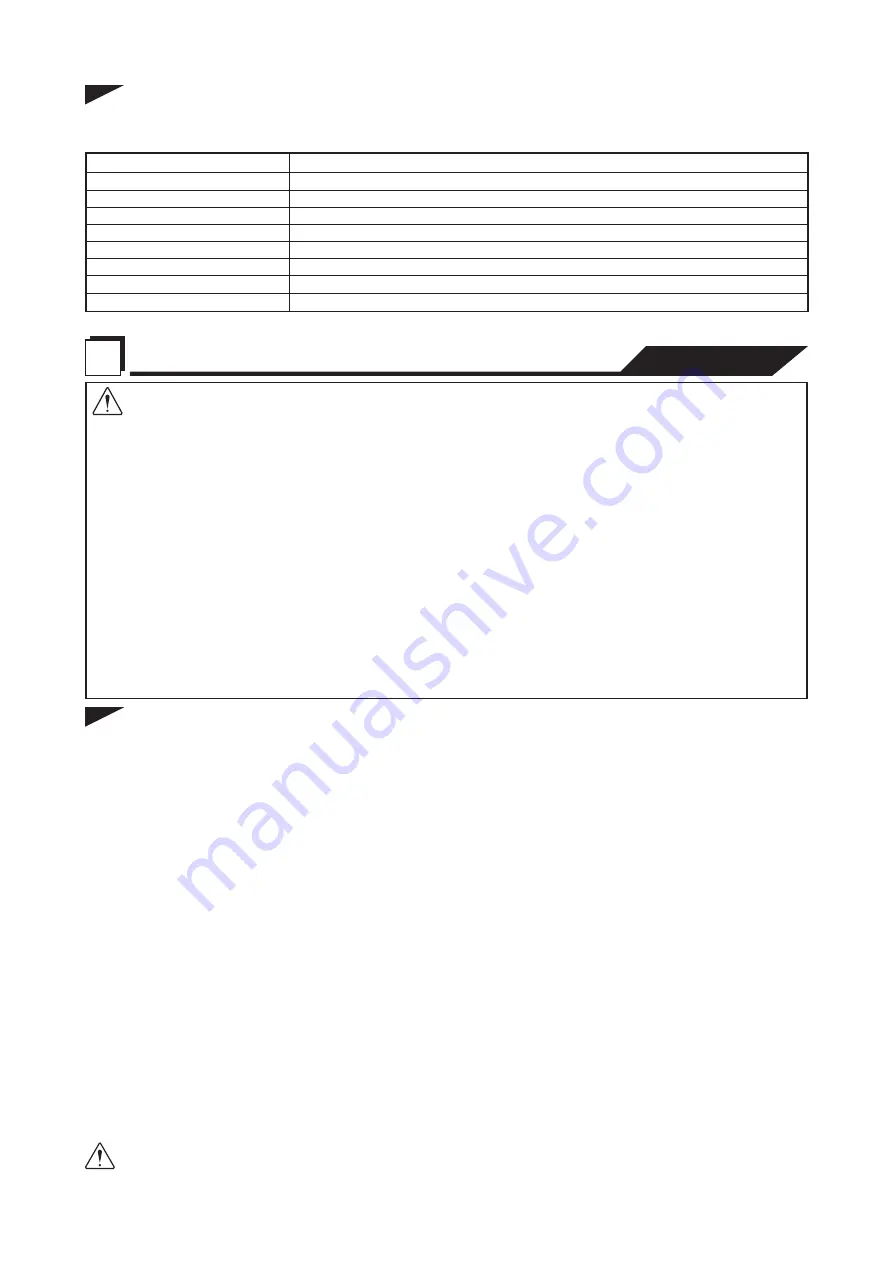

Replacement Parts

The table lists the parts that need to be replaced periodically. Replace these using the recommended

frequency as a guideline.

Mechanical Seal

Oil (Turbine Oil VG 32 )

Bearing Grease

Part

Recommended Frequency

Packing, O-Ring

Oil Seal

When oil in oil compartment becomes milky.

Every 6,000 hours of 12 months, whichever comes first.

At overhaul

Each time pump is disassembled or inspected

When the lip is worn, and each time pump is disassembled or inspected

Labyrinth Ring

Shaft Sleeve

Cathodic Protection Plate

When it becomes worn.

When it becomes worn.

When it becomes corroded.