-18-

Always turn off the power before inspecting the pump. Failure to observe this

precaution can result in serious accident.

Before ordering repairs, carefully read through this operation manual, then repeat the inspection. If the

probrem remains, contact your nearest dealer or Tsurumi representative.

WARNING

Disposal Product

Properly dispose of the product by disassembling it, presorting the contents, and sending them to the waste

material treatment site.

The following information is required when ordering repairs or making other inquiries.

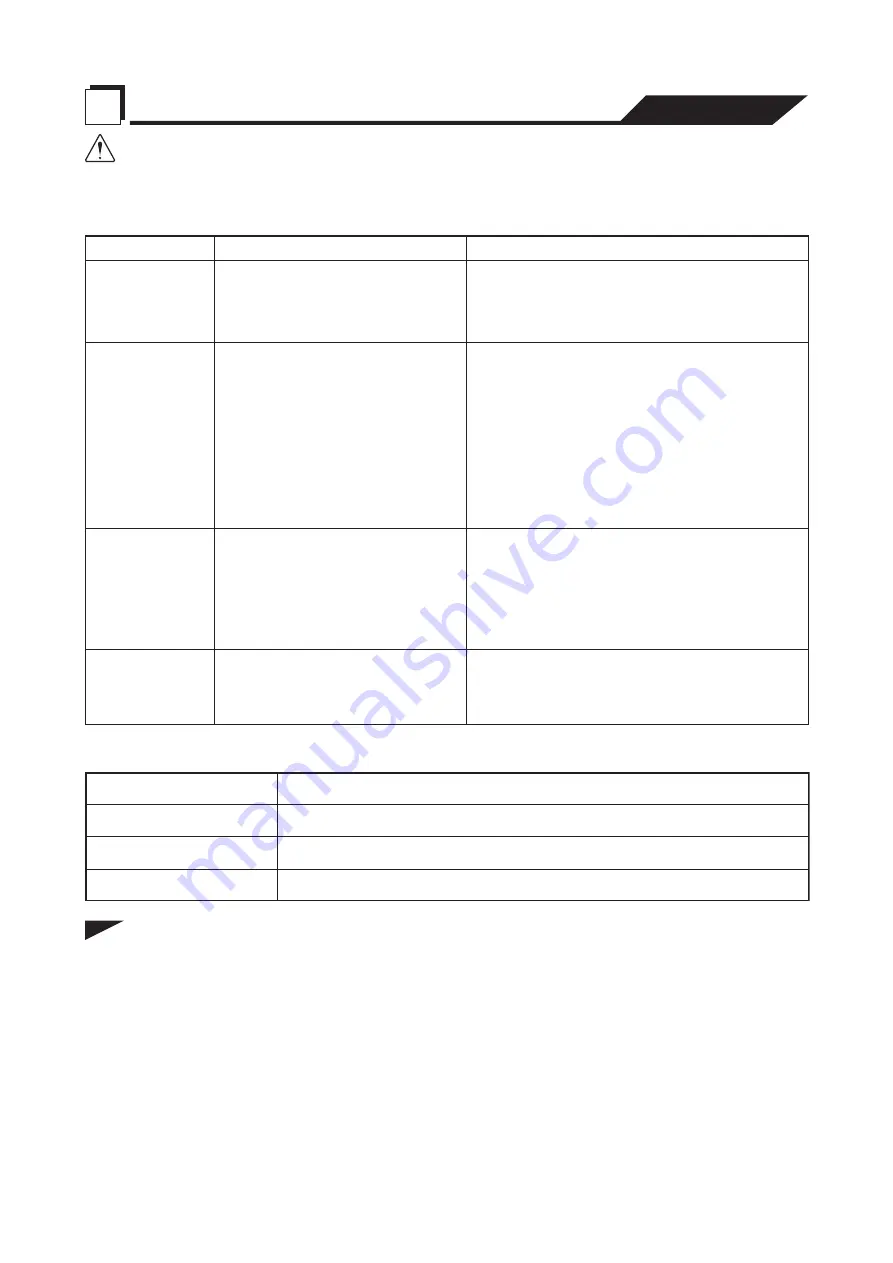

9 TROUBLESHOOTING

Remarks

Purchase date

Manufacturing number

Product model

1) Restore power.

2) Repair/replace the cable or fix the connection.

3) Inspect the pump and remove any debris.

1) Power is off.

2) Cabtyre cable is cut or not

connected properly.

3) Impeller is clogged.

1) Remove any debris.

2) Provide the rated voltage,or make sure the

cabtyre cable extension is the proper standard.

3) Check the name plate, and replace the pump.

4) Remove debris from the strainer.

5) Repair or replace the motor.

6) Place the pump on a block or other base to

prevent sand from being sucked into it.

1) Impeller is clogged.

2) Low voltage.

3) Wrong power frequency.

4) Extended operation with a

clogged strainer.

5) Faulty motor.

6) Excessive sand is discharged.

1) Add grease.

2) Contact dealer and replace motor.

1) Grease in the bearing is running

out or insufficient.

2) Damaged motor bearing.

1) Replace.

2) Straighten out any sharp bends. Enclose the

pump with a screen to keep away debris.

3) Remove debris from the strainer stand or place

a block under the pump.

4) Interchange power supply leads(p.9).

1) Worn out impeller.

2) Sharply bent or clogged hose.

3) Strainer stand clogged or buried.

4) Motor direction is reversed

Pump Will not start

Pump generates

noise or vibration

Problem

Possible cause

Countermeasure

Pump stops soon

after starting

(Motor protector

operates)

Poor lift or discharge

capacity

©

2020 TSURUMI MANUFACTURING CO., LTD.