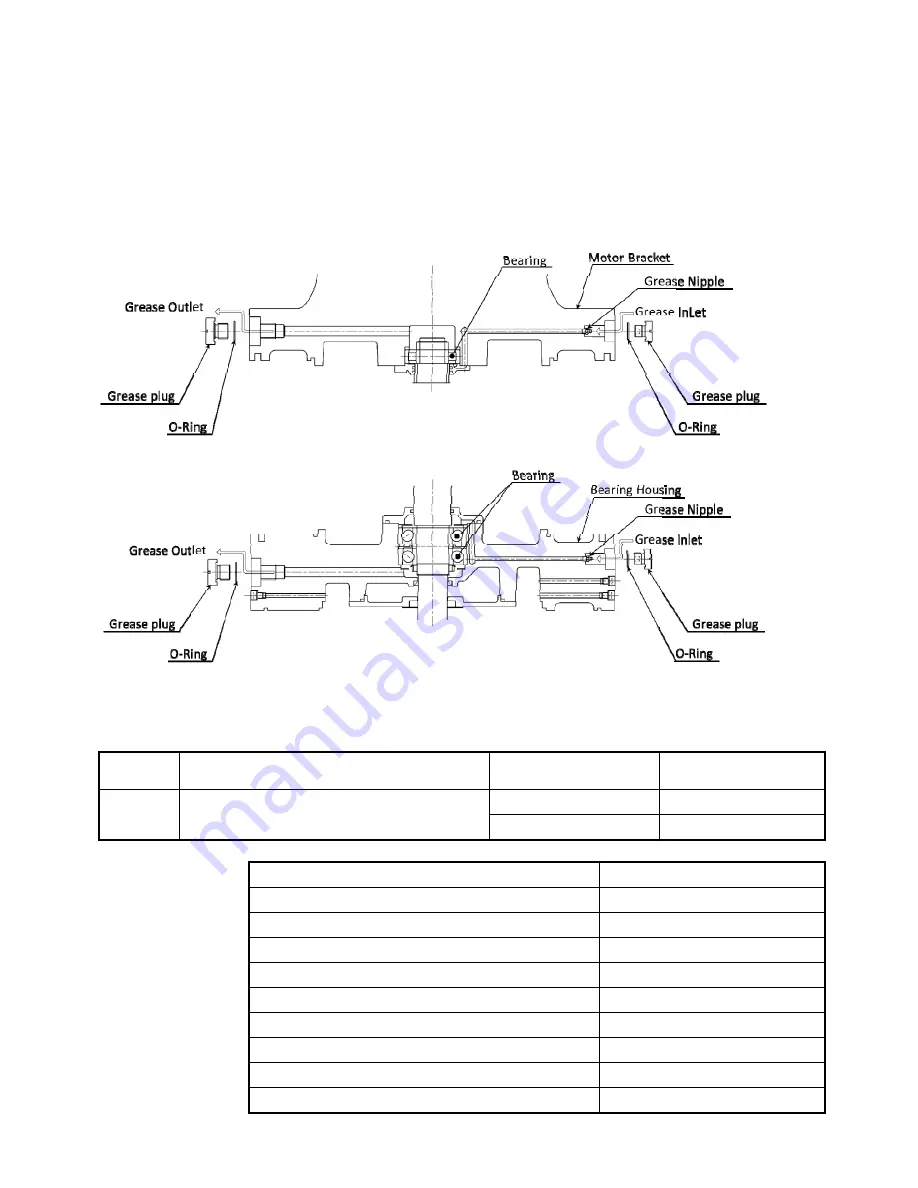

Replacing bearing grease

Models with output 185kW require that bearing grease be replaced periodically.

With the pump standing upright, supply and drain grease at the grease nipple on the bearing

housing side of lower bearing, and at the grease nipple on the motor bracket side of upper

bearing.

The table shows the different bearing types, specified amount of grease, initial supply of grease,

and replaced frequency.

Upper Bearing

Lower Bearing

Note:

Greasing generally is good for around 3,000 hours of use, but this can vary depending on

the use conditions.

Model Grease

Type

Initial

Amount

Refill

Amount

LH12185

“RAREMAX SUPER” (Kyodo Yushi Co.Ltd)

or equivalent *

1

Upper: 270g ( 9.52 oz.)

Upper: 300g (10.58 oz.)

Lower: 370g (13.15 oz.) Lower: 400g (14.11 oz.)

Item *1

Soap Type

di-Urea

Base Oil Type

Mineral Oil

Viscosity (40

o

C / 104

o

F) 94mm

2

/s (cSt)

Viscosity (100

o

C / 212

o

F) 10.5mm

2

/s (cSt)

Temperature Range

-40 to 150

o

C / -40 to 302

o

F

Dropping Point

253

o

C / 487

o

F

Penetration NLGI grade

2 to 3

Penetration (60 strokes 25

o

C / 77

o

F) 260

Penetration (100,000 strokes 25

o

C / 77

o

F) 365

max.