-7-

Avoid dry operation, which will not only lower

performance but can cause the pump to malfuncton,

leading to electrical leakage and shock.

When the pump is installed at a work site, make sure

the hose is connected in such a way as to ensure

proper drainage. Otherwise water may leak out and

cause damage to surrounding walls or flooring, or to

equipment.

(2) Install the pump in a location with sufficient water level, where water collects

readily.

Using a pump with insufficient head or operating

with a clogged strainer stand can cause excessive

vibration and noise, which may result in damage to

the pump, electrical leakage and shock.

See below, " Operating water level " (p.10) for the water level necessary for

operation.

CAUTION

CAUTION

CAUTION

Note:

(3) Run the piping as straight as possible, and avoid having the piping load applied directly to the pump.

(4) The piping should be able to withstand the recoil when the pump is started up.

(5) On the flange specification and water depth pressure resistance, see the chart on maximum allowable

water pressure.

(6) If the actual pump head (vertical life) is high, install a check valve along the piping path.

(7) Install the piping in such a way that it can be dismantled readily from outside.

(8) Arrange the piping so that air will not collect in it.

(9) When performing pipe construction, make sure welding sparks or paint do not

contact the pump.

This pump is supplied without piping. Use it with suitable piping material. The tip

of the hose (discharge end) should be located higher than the water surface. If

the end of the hose is submerged, water may f ow back to the pump when the

pump is stopped; and if the hose end is lower than the water surface, water may

overf ow when the pump is turned off.

(10) Use the pump in the upright position and on a flat surface. To prevent the

pump from becoming submerged in mud, mount it on a block or other firm

base if nesessary.

Note:

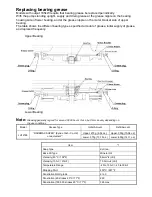

Check valve

The pump is stopped

Backflow

Outflow

(1) Avoid dropping the pump or other strong impact. Lift the pump by attaching a

rope or chain to the eye bolts.

On cabtyre cable handling, see below at Electrical Wiring (p.7)

Note:

Eyebolt

Wire Rope

Performing electrical wiring

• Eelectrical wiring should be performed by a qualified person in accord with

all applicable local regulations. Failure to observe this precaution not only

risks breaking the law but is extremely dangerous.

• Incorrect wiring can lead to electrical leakage, electrical shock or fire.

• Always make sure the pump is equipped with the specified overload

protectors and fuses or breakers, so as to prevent electrical shock from an

electrical leak or pump malfunction.

Operate well within the capacity of the power supply and wiring.

WARNING

5 ELECTRICAL WIRING