AB Connectors Limited

Specification No. 528

ABCIRP Connector Series

Assembly and wiring Instructions

AB Connectors Limited Issue 9: July 2010

Page 15 of 41

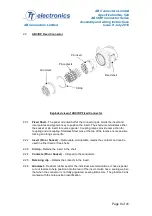

5.3.4

Checking the dimensions shown in Appendix B will verify that the contact is seated

correctly. As an extra final visual check, all contacts should be around the same

height with no visible differences in height from insert face.

5.3.5

Repeat steps 5.3.4 to 5.3.6 until all wires are located into their respective holes.

5.3.6

Slide the grommet down the cable and locate onto the insert. Lubricant such as

Pronatur or Isoproponyl alcohol may be used. Observe handling and operating safety

instructions as supplied by manufacturer.

5.3.7

Tuck the grommet in between the connector shell and the insert until the shoulder on

the grommet is pushed almost level with the top of the serrations on the shell. A

simple tool is available to help when tucking the grommet into position.

Hint: If you push forward on the back face of the grommet it should not buckle. If it does then

the grommet has not been tucked into position correctly. This can cause the grommet to tare

when the backshell is assembled and could affect sealing.

5.3.8

To ensure that the correct wire number has been inserted into the correct hole, check

that the lettering and step in the grommet align correctly.

5.3.9

Any grommet hole that has been pierced accidentally will need to be filled with a

grommet filler plug as shown. Unpierced holes can be left.

5.3.10 Slide cable idents up to the back of the grommet and leave a 5 to 15mm gap.

5.3.11 Assemble the accessory onto the connector and tighten to the recommended torque

values as stated in Appendix D.

Hint:

When engaging the accessory to the connector, linearly push the accessory onto the

fixed or free shell while rotating the accessory nut. This will ease the assembly by allowing the

threads to engage more naturally. Also continue to push the accessory inwards when

tightening to ease the torque required. The same applies during strip down; push forward on

the accessory to slacken thread.