AB Connectors Limited

Specification No. 528

ABCIRP Connector Series

Assembly and wiring Instructions

AB Connectors Limited Issue 9: July 2010

Page 4 of 41

1

Product Introduction

1.1 General

1.1.1

The ABCIRP connector series is based on the MS Bayonet lock series of connectors

conforming to MIL-C-5015 specification. They are interchangeable with all

corresponding MS bayonet lock types and feature identical panel mounting

dimensions.

1.1.2

Designed to operate within a temperature range of -55°C to +125°C, the connector

also meets the mechanical and environmental ratings of BS9522 F0032, VG95234

and NF-F-61-030.

1.1.3

Unlike other MIL-C-5015 bayonet connectors, which utilise insulators bonded into the

shell and or bonded or rubber retained contacts, the ABCIRP connector series

incorporates a Circlip retained solid plastic insulator and metal clip retained contacts.

1.1.4

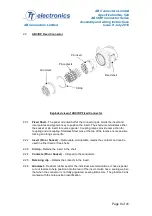

Stainless steel bayonet pins and rollers riding along the three cam tracks machined

into the receptacle shell achieve the connector coupling. Coupling integrity is

guaranteed by:

•

Firstly having three stainless steel pins at the critical wear points of the receptacle

shell cam-tracks and secondly, by positive lock indicators in the form of

•

An audible click when fully mated.

•

Alignment of coloured dots when fully mated.

1.1.5

ABCIRP connectors are available in 7 sizes from shell size 18 to shell size 40 with

arrangements having 7 to 60 contacts.

1.1.6

Crimp contacts are available in sizes 16, 12 and 8 AWG.

1.1.7

Insulator angular orientation is available for occasions where like connectors are in

close proximity and cross mating has to be avoided. This is achieved by aligning pre-

determined keyways in the insulator with the master key of the plug and receptacle

shell. These angular positions are in accordance with the MIL-C-5015 specification

thereby ensuring compatibility with existing equipment.

1.1.8

The dynamic sealing ring at the base of the plug shell guarantees high reliability and

anti-vibration characteristics including the stainless steel pins at the cam track critical

wear points.

1.1.9

Environmental sealing of mated connectors to IP67 is achieved by compression of

the dynamic seal ring, while integrity at the rear is achieved by the use of an

individual wire seal grommet with membranes being penetrated only when a wire is

present.

1.1.10 Electrical continuity between connectors is achieved by ensuring compression of the

wavy and flat washer assembly at the base of the plug shell.