T-POS Terminal -

Operator’s Guide

Page 9 of 29

1.

Select

Menu

→

Settings

→

Products

.

2.

To quickly identify the product, first use the Filter functionality.

3.

Once located,

-

.

4.

The product is now removed from the Product Catalogue and can no longer be sold.

However, it will remain in the Deleted inventory for downstream reporting purposes

and can still be viewed if Deleted is selected from the Status control.

Note: Deleting a product from the list of deleted products will result in removing the item from

the list of deleted products and in effect returning the item in the Product Catalogue making

the product available for sale again.

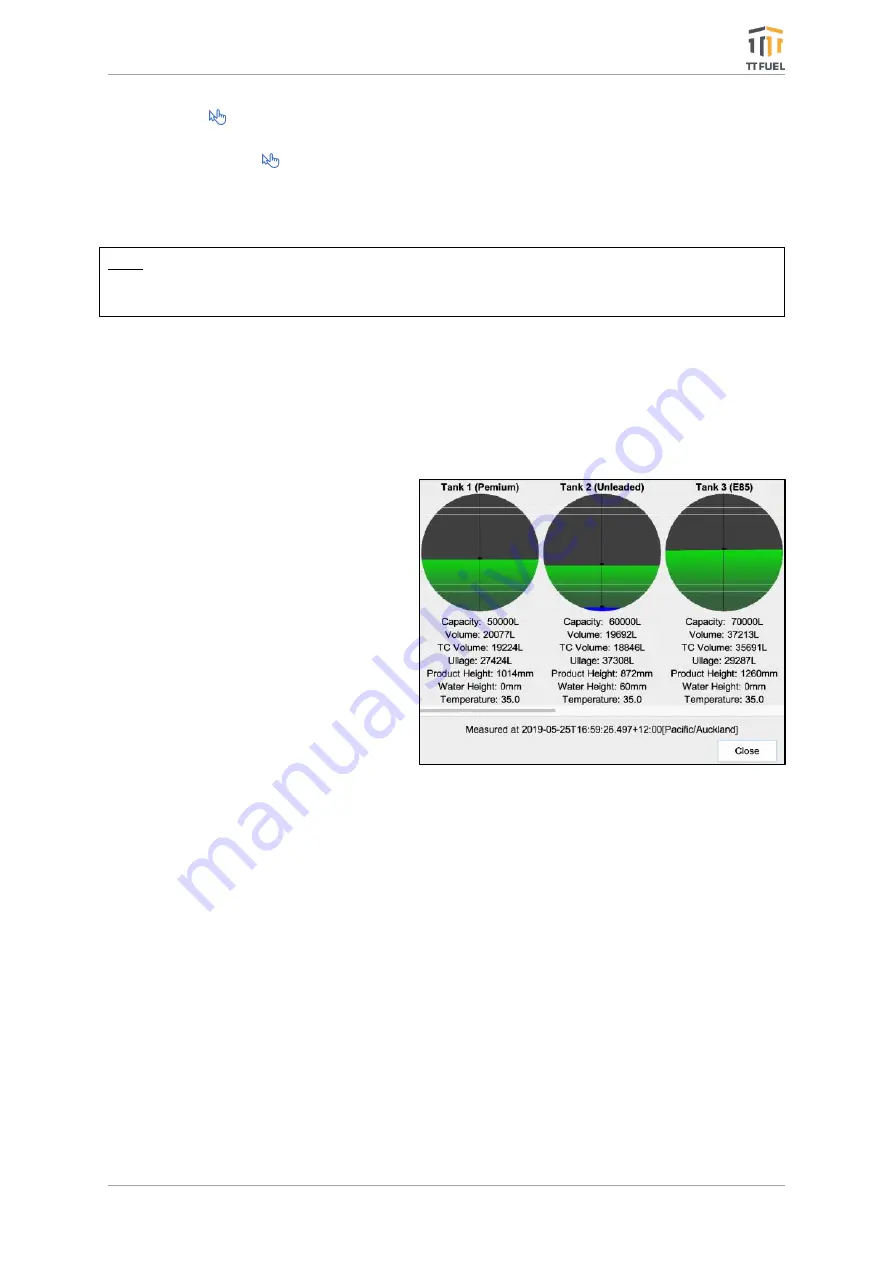

2.7

Wet-Stock Inventory Management

Inventory Management in T-POS is for the most part, automated. As products are sold, the

inventory levels are decremented,

and it’s incremented

when the product has received

additional stock, providing stock adjustments (accessed from the Products Catalogue) are

created for the inwards dry-stock goods movements.

Wet-stock too is handled in the same

way, except when delivery measurement

capable auto tank gage or ATG is used.

Here the inwards goods receipt and

measurement of wet-stock product is

automated, as the ATG automatically

records the tank delivery or drop in real

time and increments the inventory levels

accordingly.

Only when an ATG not capable of

delivery measurement is used, or

alternatively when no ATG is used and

when logical inventory is maintained

(known as theoretical gauging) does tank

delivery information need to be manually

entered.

Unlike stock adjustment, that must be made for dry-stock goods, there is a special function

available from the tanks menu to enter wet-stock product additions or fuel deliveries. A tank

delivery entry dialogue is provided for this purpose and the Operator only needs to select the

tank and enter the delivery amount, usually determined by the delivery receipt obtained from

the tanker driver.

In order to avoid confusion, it is not possible to manually enter the delivery for gaged tanks for

which this information is automatically captured. Of course, an ATG provides a real measured

inventory snapshot at the time the inventory is queried by the T-POS Operator; the inventory

levels maintained in the T-POS are synchronised to the real measured values returned at this

time. Therefore, both inwards and outwards wet-stock movements in inventory are

maintained for any type of tank.

The only other thing to consider is some sort of synchronisation for the theoretical or logically

gaged tanks, as over time the inventory levels will drift or deviate from the actual level which

Figure 3: Wet-Stock Inventory Management