Summary of Contents for Accumul8

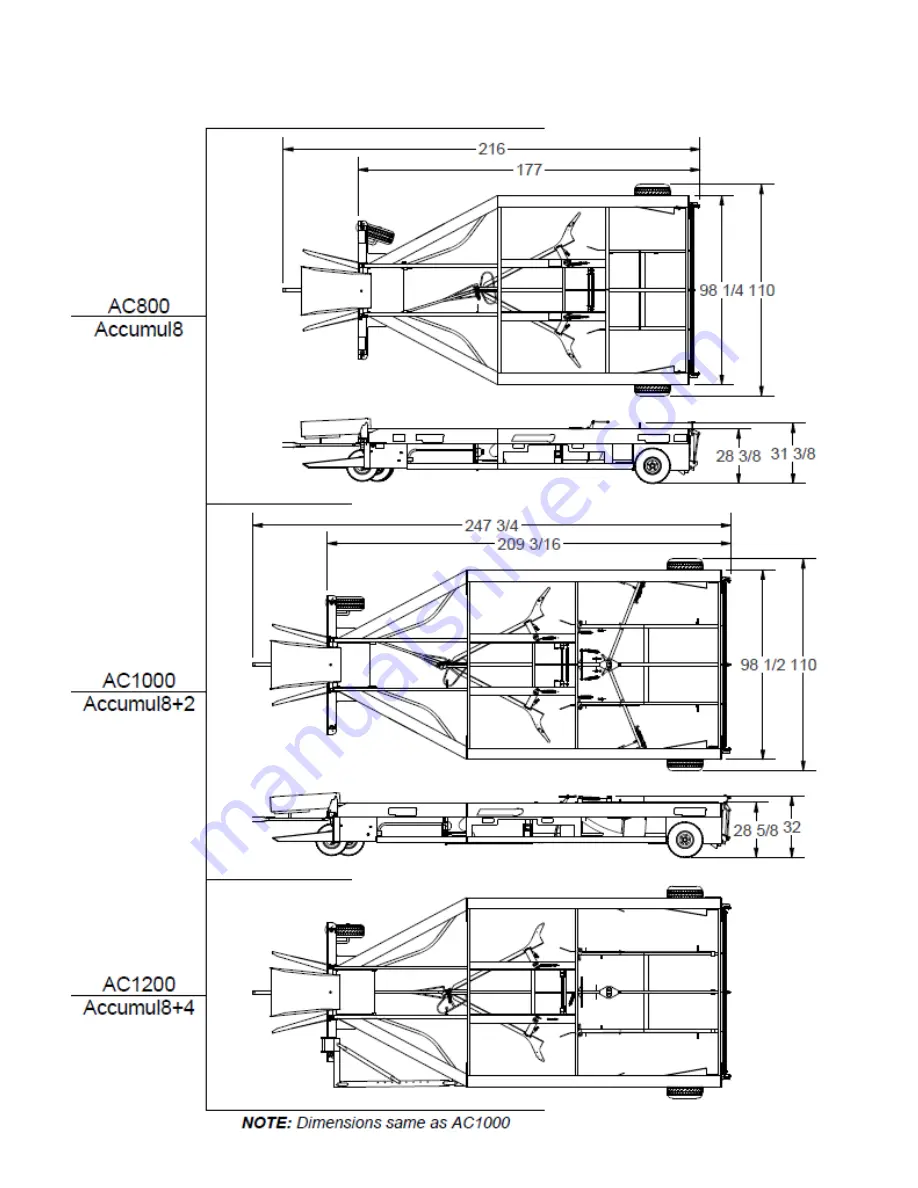

Page 5: ...1 1 Section 1 Specifications Accumul8 2 4 Section 1 Specifications Dimensions...

Page 26: ...Accumul8 2 4 Section 4 Transportation 4 6 6 Set bale slide 13 to it s raised position...

Page 40: ...Accumul8 2 4 Section 7 Parts Breakdowns Lists 7 1 Section 7 Parts Breakdowns Lists...

Page 41: ...7 2 Section 7 Parts Breakdowns Lists Accumul8 2 4 Bale Chute All Models...

Page 43: ...7 4 Section 7 Parts Breakdowns Lists Accumul8 2 4 Wheels Axles All Models...

Page 45: ...7 6 Section 7 Parts Breakdowns Lists Accumul8 2 4 Bale Gate All Models...

Page 47: ...7 8 Section 7 Parts Breakdowns Lists Accumul8 2 4 Front Bale Guides All Models...

Page 49: ...7 10 Section 7 Parts Breakdowns Lists Accumul8 2 4 Endgate All Models...

Page 53: ...7 14 Section 7 Parts Breakdowns Lists Accumul8 2 4 Swing Arms AC1000...

Page 58: ...Intentionally Left Blank...

Page 59: ...VII Torque Value Chart Imperial Accumul8 2 4 Torque Value Chart Imperial...

Page 60: ...Accumul8 2 4 Torque Value Chart Metric VIII Torque Value Chart Metric...

Page 63: ......