Boss R 4520

-

Section 9 - Control Functions 10-11

Deflector

ITEM QTY PART NUMBER

DESCRIPTION

1

4

25680

Lynch Pin 3/16 x 1.5

2

1

39354

Rubber Deflector

3

2

39356

Deflector Link

4

1

39358

Deflector Strip

5

1

40237

Deflector

6

18

HBC14X34

Hex Bolt - 1/4-20 x 3/4 Grade 8.2 Zinc Flange Bolt SAE

7

8

HBC38X114

Hex Bolt Cerrated - 3/8-16 x 1-1/4 Case Hardened Zinc Flange Bolt

8

3

HIN 3.5 X 3.5

Hinge - 3 1/2 x 3 1/2 Butt Hinge - Plain Weldable

9

18

HNC14

Hex Nut Cerrated

10

8

HNC38

Hex Nut Cerrated

Summary of Contents for Boss R 4520

Page 1: ...40252 16 01 2017 Operator s Manual...

Page 3: ...Intentionally Left Blank...

Page 19: ...8 1 Section 8 Grease Points Boss R 4520 Section 8 Grease Points...

Page 23: ...10 2 Section 9 Control Functions Boss R 4520 Frame...

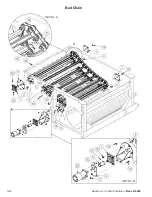

Page 25: ...10 4 Section 9 Control Functions Boss R 4520 Bed Chain...

Page 27: ...10 6 Section 9 Control Functions Boss R 4520 Bed Chain Sliders...

Page 29: ...10 8 Section 9 Control Functions Boss R 4520 Loading Arm...

Page 31: ...10 10 Section 9 Control Functions Boss R 4520 Deflector...

Page 33: ...10 12 Section 9 Control Functions Boss R 4520 Bed Dropout...

Page 35: ...10 14 Section 9 Control Functions Boss R 4520 Flail Drum...

Page 37: ...10 16 Section 9 Control Functions Boss R 4520 Flail Drum Assembly...

Page 39: ...10 18 Section 9 Control Functions Boss R 4520 Flail Drum Guards...

Page 41: ...10 20 Section 9 Control Functions Boss R 4520 Front Cover...

Page 43: ...10 22 Section 9 Control Functions Boss R 4520 Manifold Block...

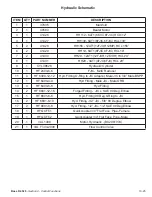

Page 45: ...10 24 Section 9 Control Functions Boss R 4520 Hydraulic Schematic...

Page 47: ...10 26 Section 9 Control Functions Boss R 4520 Electrical Schematic...

Page 48: ...Intentionally Left Blank...

Page 50: ...Boss R 4520 Section 11 Torque Value Charts 11 2 Metric Torque Values...

Page 52: ......