Nitro 275RS

-

Section 2 - Operation 2-3

Operation Safety

1. Please remember it is important that you read

and heed the safety signs on the Nitro Manure

Spreader. Clean or replace all safety signs if

they cannot be clearly read and understood.

They are there for your safety, as well as the

safety of others. The safe use of this machine

is strictly up to YOU, the operator.

2. All things with moving parts are potentially

hazardous. There is no substitute

for a cautious, safe-minded operator

who recognizes potential hazards and

follows reasonable safety practices. The

manufacturer has designed the Nitro Manure

Spreader to be used with all its safety

equipment properly attached, to minimize

the chance of accidents. Study this manual

to make sure you have all safety equipment

attached.

3.

Close and secure all guards, deflectors and

shields before starting and operating.

4. Read and understand the Owner and

Operator’s Manual before starting. Review

safety instructions annually.

5. Personal protection equipment including

safety glasses, safety shoes and gloves are

recommended during operation, adjustment,

maintaining or repairing. Do not allow long

hair, loose-fitting clothing, or jewelry to be

around moving parts.

6. Never place any part of your body where it

could be in danger if movement should occur

during assembly, installation, operation,

maintenance, repairing, unplugging or

moving.

7. Turn tractor off, remove ignition key and place

in your pocket, and wait for moving parts to

stop before servicing, adjusting, repairing or

unplugging.

8. Never use alcohol or drugs which can hinder

alertness or coordination while operating

this equipment. Consult your doctor

about operating this machine while taking

prescription medications.

9. Do not allow riders on the Nitro Manure

Spreader at any time. There is no safe place

for any riders even for troubleshooting issues.

10. Never allow children or unauthorized people

to operate or be around the Nitro Manure

Spreader.

11. Keep the working area clear of people and

other machines to prevent accidents.

12. Do not exceed a safe travelling speed when

transporting.

13. Always use extra caution when turning around

corners or in tight areas.

14. The upright beaters on the Nitro can maim or kill.

Always check for bystanders before engaging

the PTO.

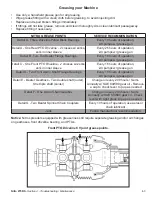

Pre-operation Checklist

It is important for both personal safety and

maintaining the good mechanical condition of the

machine that this pre-operational checklist be

followed. Before operating the machine and each

time thereafter, the following areas should be

checked off:

1. Lubricate the machine completely. Refer

to “Service” in the Service & Maintenance

section of this manual.

2. Use only a tractor of adequate power (see

PTO / Horsepower Requirements on pg. 3-1)

and weight to handle the spreader.

3. Ensure that the machine is properly attached

to the tractor using a drawbar pin with

provisions for a mechanical retainer. Make

sure that a retainer is installed.

4. Ensure that the safety chain on the hitch is

installed.

5.

Check tires and ensure that they are inflated

to the pressure specified for the spreader’s

tires.

6. Check oil level in the tractor hydraulic

reservoir. Top up as required.

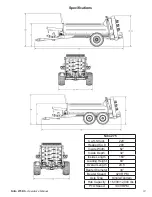

Summary of Contents for Nitro 275RS

Page 1: ...40299 Rev 1 1 18 04 2018 Operator s Manual Parts Manual...

Page 24: ...4 4 Section 4 Troubleshooting Maintenance Nitro 275RS Grease Points...

Page 25: ...Nitro 275RS Section 4 Troubleshooting Maintenance 4 5...

Page 26: ...Intentionally Left Blank...

Page 27: ...Nitro 275RS Section 5 Parts Breakdowns Lists 5 1 Section 5 Parts Breakdowns Lists...

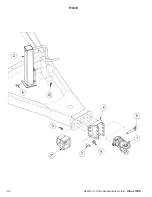

Page 28: ...5 2 Section 5 Parts Breakdowns Lists Nitro 275RS Hitch...

Page 30: ...5 4 Section 5 Parts Breakdowns Lists Nitro 275RS Front Shields...

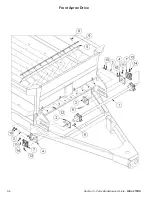

Page 32: ...5 6 Section 5 Parts Breakdowns Lists Nitro 275RS Front Apron Drive...

Page 34: ...5 8 Section 5 Parts Breakdowns Lists Nitro 275RS Driveline...

Page 36: ...5 10 Section 5 Parts Breakdowns Lists Nitro 275RS Rear Apron Drive...

Page 38: ...5 12 Section 5 Parts Breakdowns Lists Nitro 275RS Endgate...

Page 40: ...5 14 Section 5 Parts Breakdowns Lists Nitro 275RS Beaters...

Page 42: ...5 16 Section 5 Parts Breakdowns Lists Nitro 275RS Floor Side Boards...

Page 44: ...5 18 Section 5 Parts Breakdowns Lists Nitro 275RS Single Axle...

Page 46: ...5 20 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w o Scales...

Page 48: ...5 22 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w Scales...

Page 50: ...5 24 Section 5 Parts Breakdowns Lists Nitro 275RS Apron Runners...

Page 52: ...5 26 Section 5 Parts Breakdowns Lists Nitro 275RS Hydraulic Layout...

Page 54: ...Intentionally Left Blank...

Page 56: ...6 2 Section 6 Optional Features Nitro 275RS Light Kit Assembly...

Page 58: ...6 4 Section 6 Optional Features Nitro 275RS Light Kit Wiring Harness...

Page 60: ...6 6 Section 6 Optional Features Nitro 275RS Flow Control Hydraulics...

Page 62: ...6 8 Section 6 Optional Features Nitro 275RS Electric Flow Control Wiring...

Page 64: ...6 10 Section 6 Optional Features Nitro 275RS N750LC GT400 N750LCNT460 Scales...

Page 65: ...Nitro 275RS Section 6 Optional Features 6 11 N750LCNT8000 Scales...

Page 67: ...Nitro 275RS Section 7 PTOs 7 1 Section 7 PTOs...

Page 68: ...7 2 Section 7 PTOs Nitro 275RS 39850 PTO 375 450 525 600 750 V80 141P028359 028028 CV80 CLS...

Page 70: ...7 4 Section 7 PTOs Nitro 275RS 39852 PTO 600 750 T60 086P265011 306028 CLS 2500NM...

Page 72: ...VII Torque Value Chart Imperial Nitro 275RS Torque Value Chart Imperial...

Page 73: ...Nitro 275RS Torque Value Chart Metric VIII Torque Value Chart Metric...

Page 76: ......