2-4

Section 2 - Operation -

Nitro 275RS

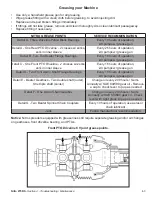

WARNING :

Use extreme care when working

around a high pressure hydraulic system. Make

sure all connections are tight and all components

are in good repair. Wear hand and eye protection

then searching for suspected leaks.

7.

Inspect all hydraulic lines, hoses, fittings

and couplers for tightness. Tighten if there

are leaks. Use a clean cloth to wipe any

accumulated dirt from the couplers before

connecting to the

tractor’s hydraulic system.

See “

” in the Troubleshooting

/ Maintenance section of this manual.

8. Inspect all moving and rotating parts. Remove

any debris that has become entangled in the

rear beaters or the PTO drive line.

9. Make sure that all guards and shields are

installed and secured in position.

10. Check the oil level in the gearboxes. Top up

as required.

11. Ensure that the PTO driveline is securely

attached on both ends and can telescope

easily. Check that the PTO driveline shield

rotates freely.

Loading

WARNING :

When parking the spreader for

loading, put the tractor in PARK or NEUTRAL and

apply the parking brake.

1. Fully Close Rear Hydraulic Gate

2. Load the Spreader

The manure consistency will determine how full

your spreader can be loaded. Solid manure can

usually be loaded level to slightly heaped. Wet

materials are heavier and may limit loading.

NOTICE

: It is unlawful to allow any manure

spillage to occur on public roadways. Do not

heap load such that manure is allowed to fall off

spreader during transporting on roadways.

Always check the apron chain and slats to make

sure they are not frozen to the bottom of the bed.

Operating the spreader when the slats or chain

are frozen to the bed may cause damage. Also

make sure there are no lumps of manure frozen

to the floor.

It is recommended to make sure the apron chain

is operating properly before loading the spreader.

Unloading

1. Engage the Rear Beaters.

2. Fully Open Rear Gate

Fully extend the cylinders so the gate is fully

open all the way to the top.

NOTICE : Before starting the apron chain, the

operator should get the beaters up to speed and

open the rear gate to desired height.

Turn on the tractor hydraulics used to start the

apron chain. The hydraulics adjust the speed at

which material is being pulled towards the rear

beaters. The slower the speed - the finer the

spread as the rear beaters have more time to

“process” the material.

See Optional Flow Control

if applicable to your Nitro Manure Spreader.

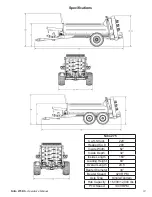

Summary of Contents for Nitro 275RS

Page 1: ...40299 Rev 1 1 18 04 2018 Operator s Manual Parts Manual...

Page 24: ...4 4 Section 4 Troubleshooting Maintenance Nitro 275RS Grease Points...

Page 25: ...Nitro 275RS Section 4 Troubleshooting Maintenance 4 5...

Page 26: ...Intentionally Left Blank...

Page 27: ...Nitro 275RS Section 5 Parts Breakdowns Lists 5 1 Section 5 Parts Breakdowns Lists...

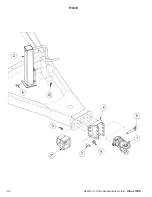

Page 28: ...5 2 Section 5 Parts Breakdowns Lists Nitro 275RS Hitch...

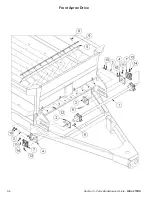

Page 30: ...5 4 Section 5 Parts Breakdowns Lists Nitro 275RS Front Shields...

Page 32: ...5 6 Section 5 Parts Breakdowns Lists Nitro 275RS Front Apron Drive...

Page 34: ...5 8 Section 5 Parts Breakdowns Lists Nitro 275RS Driveline...

Page 36: ...5 10 Section 5 Parts Breakdowns Lists Nitro 275RS Rear Apron Drive...

Page 38: ...5 12 Section 5 Parts Breakdowns Lists Nitro 275RS Endgate...

Page 40: ...5 14 Section 5 Parts Breakdowns Lists Nitro 275RS Beaters...

Page 42: ...5 16 Section 5 Parts Breakdowns Lists Nitro 275RS Floor Side Boards...

Page 44: ...5 18 Section 5 Parts Breakdowns Lists Nitro 275RS Single Axle...

Page 46: ...5 20 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w o Scales...

Page 48: ...5 22 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w Scales...

Page 50: ...5 24 Section 5 Parts Breakdowns Lists Nitro 275RS Apron Runners...

Page 52: ...5 26 Section 5 Parts Breakdowns Lists Nitro 275RS Hydraulic Layout...

Page 54: ...Intentionally Left Blank...

Page 56: ...6 2 Section 6 Optional Features Nitro 275RS Light Kit Assembly...

Page 58: ...6 4 Section 6 Optional Features Nitro 275RS Light Kit Wiring Harness...

Page 60: ...6 6 Section 6 Optional Features Nitro 275RS Flow Control Hydraulics...

Page 62: ...6 8 Section 6 Optional Features Nitro 275RS Electric Flow Control Wiring...

Page 64: ...6 10 Section 6 Optional Features Nitro 275RS N750LC GT400 N750LCNT460 Scales...

Page 65: ...Nitro 275RS Section 6 Optional Features 6 11 N750LCNT8000 Scales...

Page 67: ...Nitro 275RS Section 7 PTOs 7 1 Section 7 PTOs...

Page 68: ...7 2 Section 7 PTOs Nitro 275RS 39850 PTO 375 450 525 600 750 V80 141P028359 028028 CV80 CLS...

Page 70: ...7 4 Section 7 PTOs Nitro 275RS 39852 PTO 600 750 T60 086P265011 306028 CLS 2500NM...

Page 72: ...VII Torque Value Chart Imperial Nitro 275RS Torque Value Chart Imperial...

Page 73: ...Nitro 275RS Torque Value Chart Metric VIII Torque Value Chart Metric...

Page 76: ......