3-2

Section 3 - Transportation / Storage -

Nitro 275RS

Travel Speed

A suggested starting speed is between 4-5 mph.

This can be adjusted to operator preference.

WARNING:

Normally, the load itself blocks

manure and loose materials from being thrown

towards the front. As the load/pile gets reduced,

the rotation of the rear beaters can throw

some material forward, therefore it is strongly

recommended to lower the rear gate about 1/3

of the way down to prevent debris from being

projected towards the front.

Unplugging

The following is a recommended procedure

that may help if the manure spreader becomes

plugged or the PTO disengages:

1. Disengage the hydraulics that run the apron

chain.

2.

Reverse the apron chain by flipping your

tractor hydraulic lever.

3. Engage the hydraulics to reverse the apron chain

in order to back material away from beaters.

Stop apron chain after material is backed

away from beaters or if pile doesn’t move.

WARNING:

Reversing chain under full load will

cause front aporn shaft to bend and/or break.

4. Engage the beaters. Bring beaters back up to

regular speed.

5. Follow the instructions in the

Unloading

section (pg. 2-4) to start the apron chain in the

standard operation direction.

If this above procedure does not solve the

situation, closer inspection and possible manual

unplugging may be required. Make sure to stop

tractor and wait for all moving parts to stop before

servicing or unplugging:

WARNING:

Stop tractor engine, place all controls

in neutral, set park brake, remove ignition key

and wait for all moving parts to stop before

servicing, adjusting, repairing or unplugging.

Storage and Cleaning

Disconnect PTO drive shaft and hydraulic

hoses before cleaning, adjusting, lubricating, or

servicing this machine.

1. The spreader must be thoroughly cleaned

for extended storage. Manure is acidic and

will damage paint and cause rusting of metal

components.

2. Allow the spreader to completely unload.

3. To clean the spreader, raise the rear gate.

WARNING: Turn off all power during cleaning

and inspection. Do not use power to move

any components or to discharge material

while cleaning or inspecting.

4. Hose off manure from the outside and inside

of the spreader. Completely clean manure

from moving mechanisms such as the beaters

and rear gate. Remove accumulation in

confined areas or pockets that trap manure.

5. Avoid directing high pressure spray directly on

bearings, seals and flow control valve.

6. Keep high pressure spray moving on painted

surfaces. Sustained spray on cracks or

scratches in paint can result in paint peeling.

7. Allow machine to dry.

8. Lower rear gate completely down before

storing spreader.

9. Inspect the spreader for loose connections,

damaged hydraulic hoses or connections

and for other damaged components. Repair if

necessary so the spreader is ready for future

operation. See Hydraulic Safety on

Summary of Contents for Nitro 275RS

Page 1: ...40299 Rev 1 1 18 04 2018 Operator s Manual Parts Manual...

Page 24: ...4 4 Section 4 Troubleshooting Maintenance Nitro 275RS Grease Points...

Page 25: ...Nitro 275RS Section 4 Troubleshooting Maintenance 4 5...

Page 26: ...Intentionally Left Blank...

Page 27: ...Nitro 275RS Section 5 Parts Breakdowns Lists 5 1 Section 5 Parts Breakdowns Lists...

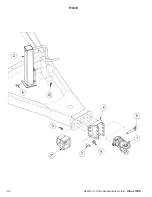

Page 28: ...5 2 Section 5 Parts Breakdowns Lists Nitro 275RS Hitch...

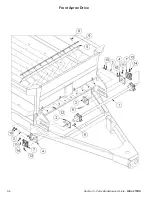

Page 30: ...5 4 Section 5 Parts Breakdowns Lists Nitro 275RS Front Shields...

Page 32: ...5 6 Section 5 Parts Breakdowns Lists Nitro 275RS Front Apron Drive...

Page 34: ...5 8 Section 5 Parts Breakdowns Lists Nitro 275RS Driveline...

Page 36: ...5 10 Section 5 Parts Breakdowns Lists Nitro 275RS Rear Apron Drive...

Page 38: ...5 12 Section 5 Parts Breakdowns Lists Nitro 275RS Endgate...

Page 40: ...5 14 Section 5 Parts Breakdowns Lists Nitro 275RS Beaters...

Page 42: ...5 16 Section 5 Parts Breakdowns Lists Nitro 275RS Floor Side Boards...

Page 44: ...5 18 Section 5 Parts Breakdowns Lists Nitro 275RS Single Axle...

Page 46: ...5 20 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w o Scales...

Page 48: ...5 22 Section 5 Parts Breakdowns Lists Nitro 275RS Tandem Axle w Scales...

Page 50: ...5 24 Section 5 Parts Breakdowns Lists Nitro 275RS Apron Runners...

Page 52: ...5 26 Section 5 Parts Breakdowns Lists Nitro 275RS Hydraulic Layout...

Page 54: ...Intentionally Left Blank...

Page 56: ...6 2 Section 6 Optional Features Nitro 275RS Light Kit Assembly...

Page 58: ...6 4 Section 6 Optional Features Nitro 275RS Light Kit Wiring Harness...

Page 60: ...6 6 Section 6 Optional Features Nitro 275RS Flow Control Hydraulics...

Page 62: ...6 8 Section 6 Optional Features Nitro 275RS Electric Flow Control Wiring...

Page 64: ...6 10 Section 6 Optional Features Nitro 275RS N750LC GT400 N750LCNT460 Scales...

Page 65: ...Nitro 275RS Section 6 Optional Features 6 11 N750LCNT8000 Scales...

Page 67: ...Nitro 275RS Section 7 PTOs 7 1 Section 7 PTOs...

Page 68: ...7 2 Section 7 PTOs Nitro 275RS 39850 PTO 375 450 525 600 750 V80 141P028359 028028 CV80 CLS...

Page 70: ...7 4 Section 7 PTOs Nitro 275RS 39852 PTO 600 750 T60 086P265011 306028 CLS 2500NM...

Page 72: ...VII Torque Value Chart Imperial Nitro 275RS Torque Value Chart Imperial...

Page 73: ...Nitro 275RS Torque Value Chart Metric VIII Torque Value Chart Metric...

Page 76: ......