Maintenance

60

50-hour maintenance / weekly

Wheel nuts

WARNING!

Loose wheel nuts can cause accidents.

•

Check the wheel nuts regularly for tightness.

000046

1

1. Check the wheel nuts (1) for tightness and tighten the wheel

nuts using a torque wrench to 70 Nm an.

– Daily in the first week

– Thereafter every 50 operating hours or weekly

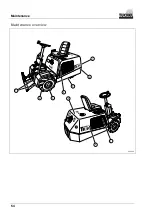

Lubricating points

1. Lubricate the following points with grease according to the

table

"Lubricants and operating

materials

"; page 51

.

•

Lower link

000014

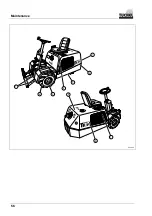

•

Steering cylinder

000015

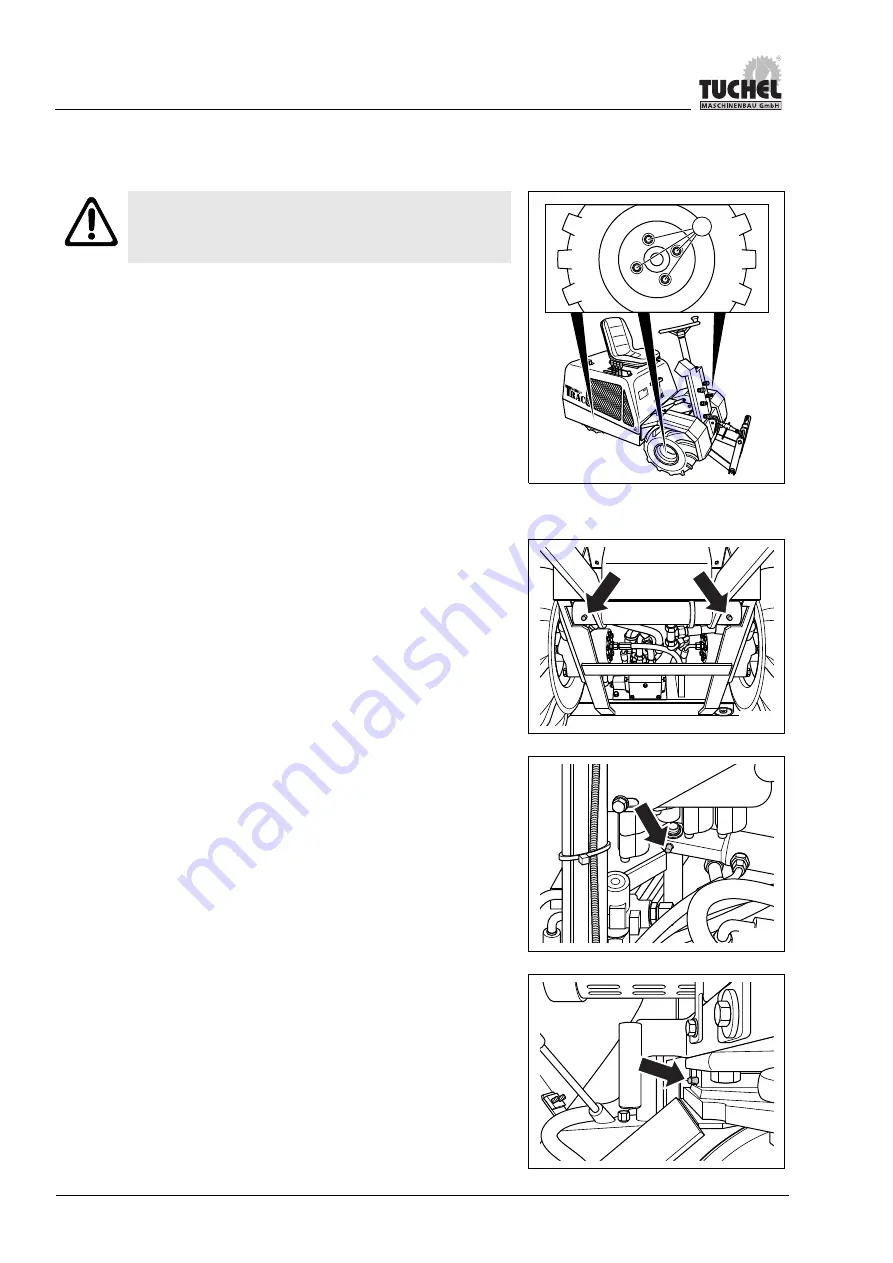

•

Steering knuckle (steerable rear wheel)

000016