16

Check that the hose is not kinked or under tension.

Apart from the connection point the hose must not

be touching any part of the Barbecue or Wok burner

where it may get hot and be damaged.

For storage, cylinder exchange or refilling,

disconnect the hose at the cylinder only.

Do not

disconnect the hose from the appliance.

Do not

attempt to open or adjust the regulator, if

you think it is not working properly consult your local

dealer.

FOR PERMANENT CONNECTIONS to natural gas or

a fixed propane supply, an authorised person, in

accordance with these instructions, local gas fitting

regulations, municipal building codes, the AGA

installation code AS5601 and any other relevant

statutory regulations, must be employed.

For connection to a natural gas bayonet fitting,

a gas regulator must be fitted at the inlet of the

appliance, and an approved 10mm, class A, natural

gas hose (no longer than 2 metres), going from the

gas regulator to the bayonet point, complying with

AS1869 must be used.

Where a mobile appliance is to be connected to

a fixed gas supply via a flexible hose connection

the restraining cord supplied must be fixed to the

appliance and the wall/floor within 50mm of each

connection point. The length of the restraining cord

shall not exceed 80% of the length of the hose as it

is designed to prevent stress on the hose assembly

when the appliance is moved out of its normal

operating position.

It is recommended that an isolation valve and union

be fitted before the barbecue; refer AS5601/ AG601

for correct pipe sizing to ensure adequate gas is

supplied to the appliance.

For natural gas check the pressure of the regulator

and adjust it if necessary to the pressure shown on

the data plate.

GAS INSTALLATION

PROPANE GAS TO NATURAL GAS

CONVERSION PROCEDURE FOR

AUTHORIZED INSTALLER

•

Disconnect the gas supply and remove the plate,

grills, flare guards and burners from the barbecue

and the Wok burner if fitted.

•

Remove the main injectors and replace them

with the correct 1.7mm injectors for each main

burner. If wok burner fitted replace the injector

with the correct size required. (see data plate)

•

Re-assemble the burners, flare guards, plate and

grills.

•

Replace the PROPANE GAS hose and regulator

with an approved natural gas regulator and

hose.

•

Turn the gas on and test for leaks, repair if

necessary.

•

Light 3 burners and turn them to high and set the

pressure at 1 KPA.

•

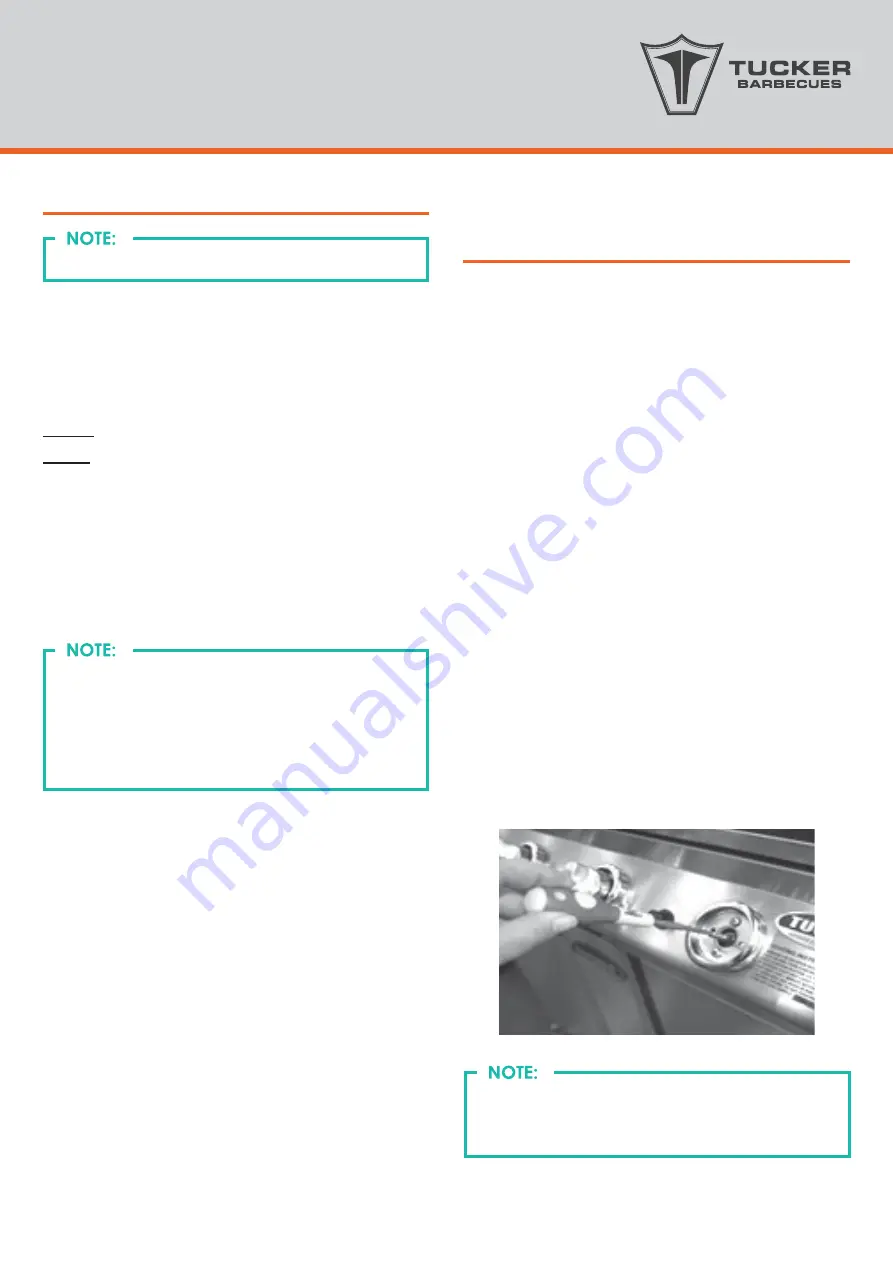

Now turn all the burners to the “LOW” setting and

check the flame pattern is steady, if necessary

you can adjust the low setting by removing the

gas control knobs and insert the 2.4mm slotted

screw driver supplied into the valve shaft, the

“low” setting can be adjusted up or down to suit

your gas pressure by turning the screw driver.

•

Turn the screw driver anti-clockwise to adjust

the flame height up or turn it clockwise to Turn it

down.

Check for leaks after each gas refill.

The installer must test the BBQ when the

installation is completed before leaving to

make sure the appliance operates correctly

and is safe for the operator to use. The gas inlet

connection must have a thread in

accordance with AS ISO 7.1 or AS 1722.2.

You want to achieve the lowest flame height at

“LOW” but you don’t want to adjust it too low as

it could blow out on its own or due to a breeze.