12

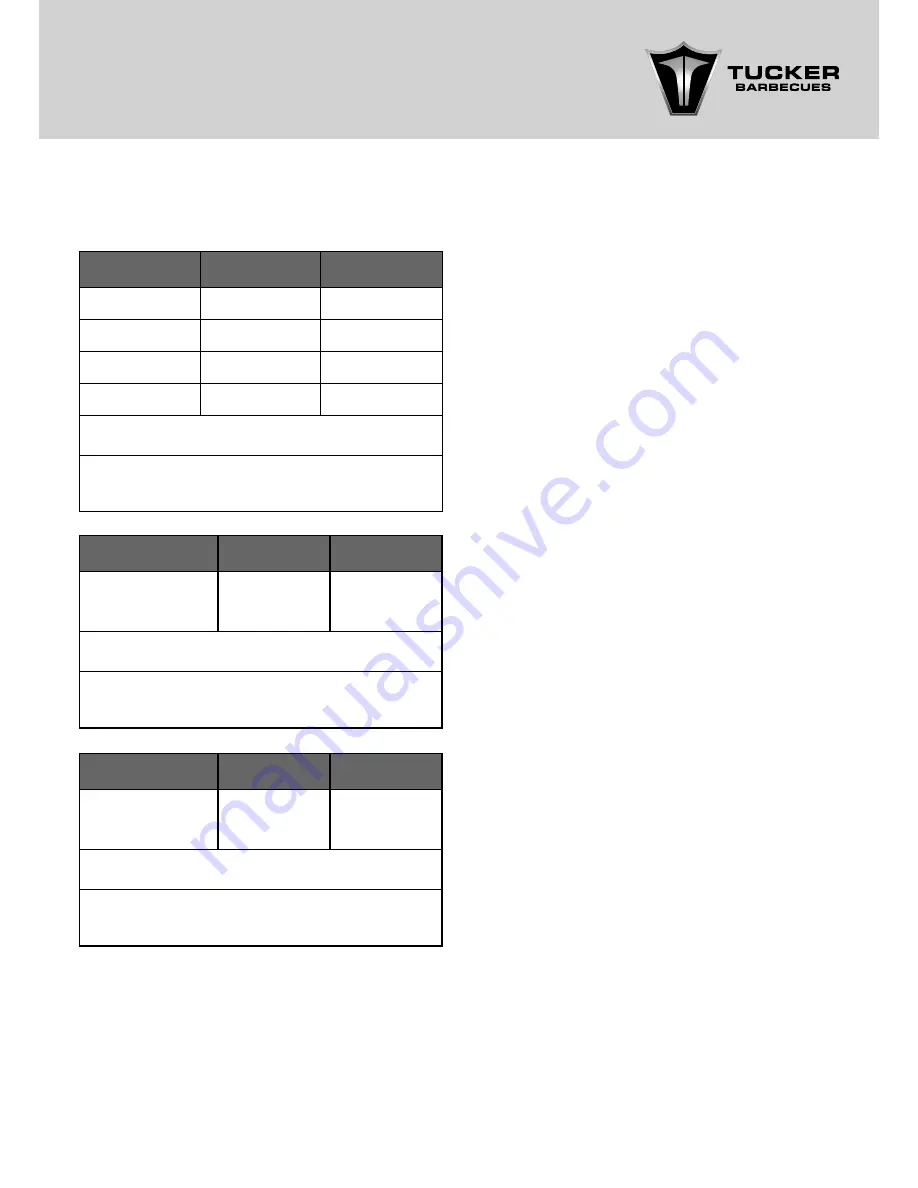

BARBECUE GAS CONSUMPTION

TUCKER GTR BARBECUES ARE MADE AND

APPROVED TO AUSTRALIAN STANDARDS

A.G.A. APPROVAL NO. AGA 8236-G

SPECIFICATIONS

(In Mega Joules Per Hour)

Model

Natural Gas

LPG:

GTR3

39mj

40.5mj

GTR4

52mj

54mj

GTR5

65mj

67.5mj

GTR6

78mj

81mj

Natural Gas injector size 1.7mm Pressure 1KPA

Propane Gas injector size 1 mm Pressure

2.75 KPA

Model

Natural Gas

LPG:

Integrated

S Wok/ST Wok

12.5mj

15mj

Natural Gas injector size 1.8mm Pressure 1KPA

Propane Gas injector size 1.1 mm Pressure

2.75 KPA

Model

Natural Gas

LPG:

Integrated SS

Wok

17mj

18mj

Natural Gas injector size 1.9mm Pressure 1KPA

Propane Gas injector size 1.1 mm Pressure

2.75 KPA

For LP Gas connections, an approved 2.75 KPA

regulator and hose assembly connection to the

appliance is fitted by the manufacturer.

The appliance inlet is 3/8 S.A.E. male and

is located in the base of the BBQ, on the

righthand side at the front.

The minimum capacity propane cylinder for this

barbecue is 4 KG.

Warning in freezing conditions the pressure of

Propane gas can be reduced in the Cylinder

Tank causing a lack of gas pressure, this may

affect the way the barbecue operates.

The intended use of this barbecue is to be

installed into a Tucker GTR Cabinet Trolley,

Pedestal Trolley, Chef Stand or into a Tucker

Zero Clearance Insulation Jacket.

Alternatively, it may be set into brickwork.

Be sensible about the location of your

barbecue.

The barbecue must be located on firm and

level ground.

Do not locate the barbecue near combustible

materials or surfaces, either above or around

the barbecue.

Do not obstruct any of the air ventilation

openings on the front of the barbecue.