8

BRAKE ADJUSTMENT

BRAKE ADJUSTMENT

BRAKE ADJUSTMENT

BRAKE ADJUSTMENT

In general, worm brakes on Tulsa winches should be set to hold the load you are

currently working with. Excessive brake torque will result in excessive heat generation

and brake wear. The best way to insure proper brake adjustment is to pull the cable

tight against the load and stop to ensure the brake holds. If it doesn’t, tighten the brake

slightly and try it again. If the brake doesn’t respond to adjustment the brake must be

serviced.

If the input to the winch is accessible and a torque wrench can be adapted to it, the

brake can be set with a torque wrench. The Model 34 brake is shipped from the factory

pre-set at 70 Ft.-Lbs.

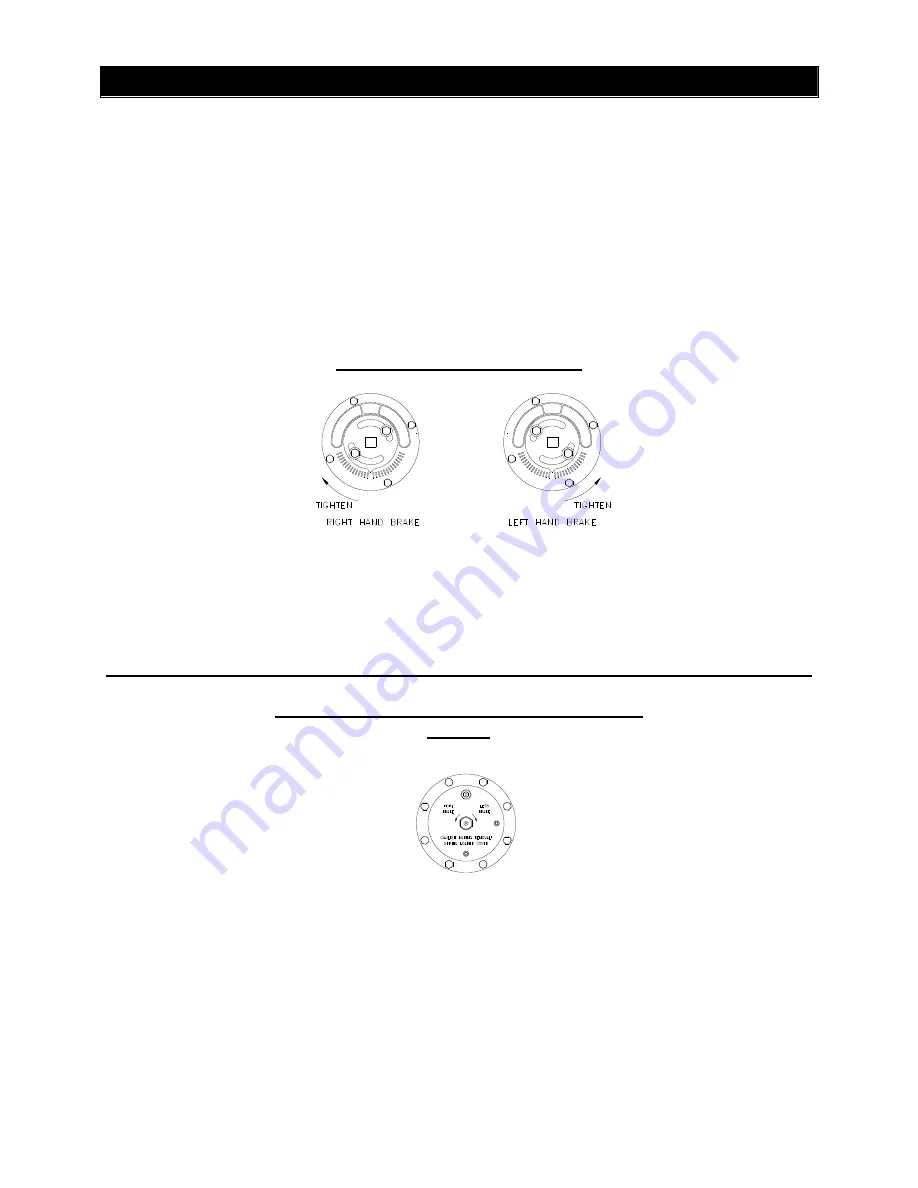

ADJUSTABLE SHOE BRAKE

To tighten the brake, loosen the two capscrews in the slotted holes and rotate the brake

in the direction shown. If the brake needs to be reversed, remove those same two

capscrews, rotate the cam 60 degrees and reinstall the capscrews in the other set of

holes which have just been revealed. After adjustment, be sure to re-tighten the cam

capscrews securely.

ADJUSTABLE MULTIPLE DISC OIL BRAKE

RN30W

This style of brake can be adjusted by turning the hex adjuster counter-clockwise to

increase brake and clockwise to decrease brake. The direction of braking for all multiple

disc brakes can be changed by removing the cam clutch, turning it over, and re-

installing it. For detailed service instructions, contact your Tulsa Winch distributor or the

factory.

If the input to the winch is accessible and a torque wrench can be adapted to it, the

brake can be set with a torque wrench. The RN30W brake is shipped from the factory

pre-set at 70 Ft.-Lbs.