6

MAINTENANCE

Tulsa Winch worm gear driven winches require regular maintenance to ensure safe

and reliable operation. Regular oil changes with the correct oil for the ambient

temperature conditions and an annual inspection of the wear components are strongly

recommended.

Maintenance Scheduling

The owner is to ensure proper inspection intervals, in compliance with the API RP

2D Section 4, ANSI B30.5, 5-2.3, or ANSI B30.7, 7-2.1, and will review winch usage

categories on a periodic basis. A qualified inspector should perform all maintenance

and inspections.

Oil Maintenance

The oil in the gear section and the brake section should be changed every

1000 hrs

or

6 months

of normal usage. If your winch is mounted with a drum brake, do not fill

brake with oil.

•

Tulsa Winch recommends that the oil level in the gearbox be checked and

adjusted as part of the pre-use inspection. If the oil level drops frequently or oil

leakage is detected during an inspection, maintenance should be performed to

correct any problems.

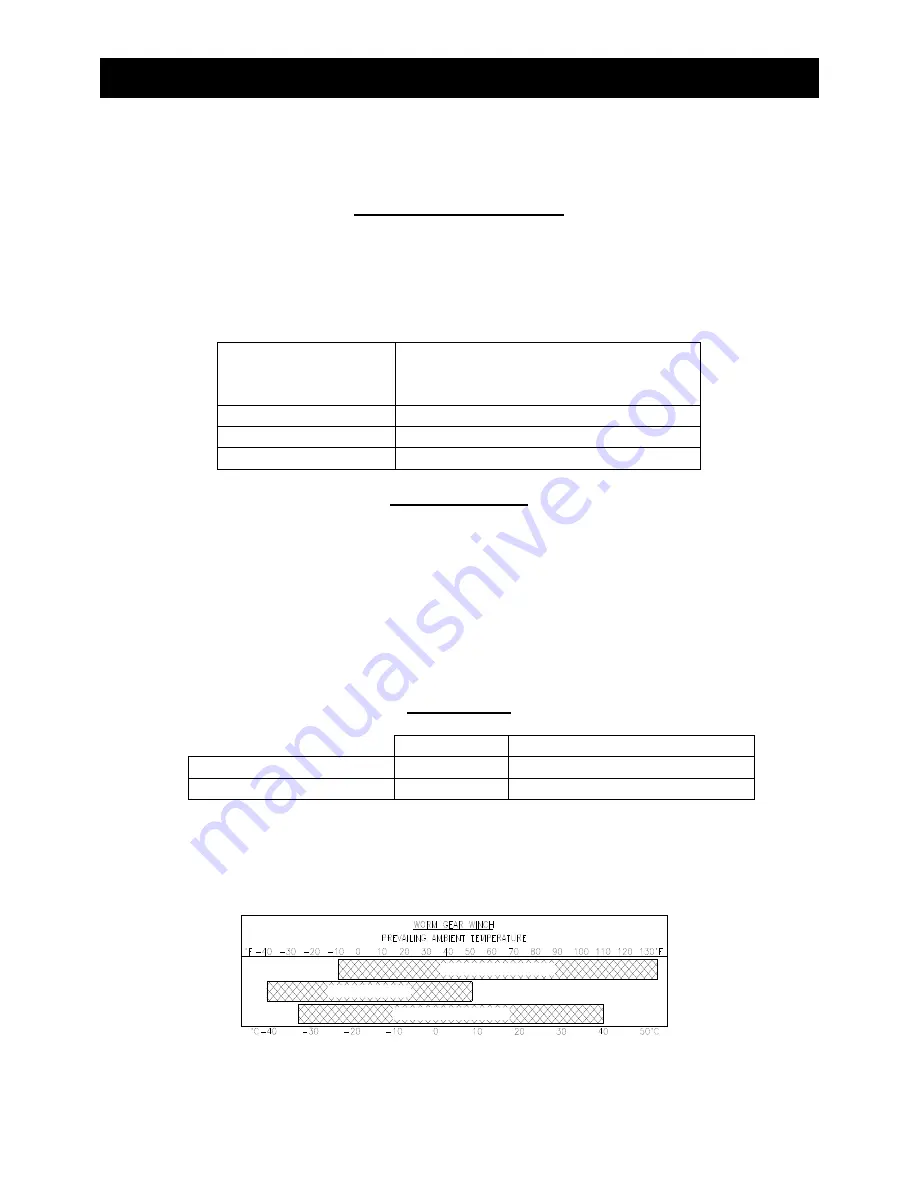

Oil Capacity

AMOUNT

OIL

TYPE

GEARBOX SECTION

5.00 QTS SEE CHART BELOW

BRAKE SECTION

TO LEVEL LIGHTWEIGHT NON-EP*

•

Gearbox oil level inspection is achieved by removing the oil level inspection plug

and visually inspecting the oil level. Minimum oil level is to the bottom of the

threads of the inspection hole. Refer to the chart below for the recommended oil

type and grade for your application.

All oils must meet MIL-PRF2105E standards. Substitution from a reputable

manufacturer is allowed as long as type and grade are maintained.

USE

(HRS PER

MONTH)

API RP 2D RECOMMENDED

INSPECTION SCHEDULE

0-10 PRE-USE,

ANNUAL

11-50 PRE-USE,

QUARTERLY

51+ PRE-USE,

MONTHLY

MOBIL SHC 626

MOBILUBE HD80W140

SAE 140W AGMA 7 EP

*SAE 20W, AUTOMATIC TRANSMISSION FLUID, OR MOST HYDRAULIC OILS.