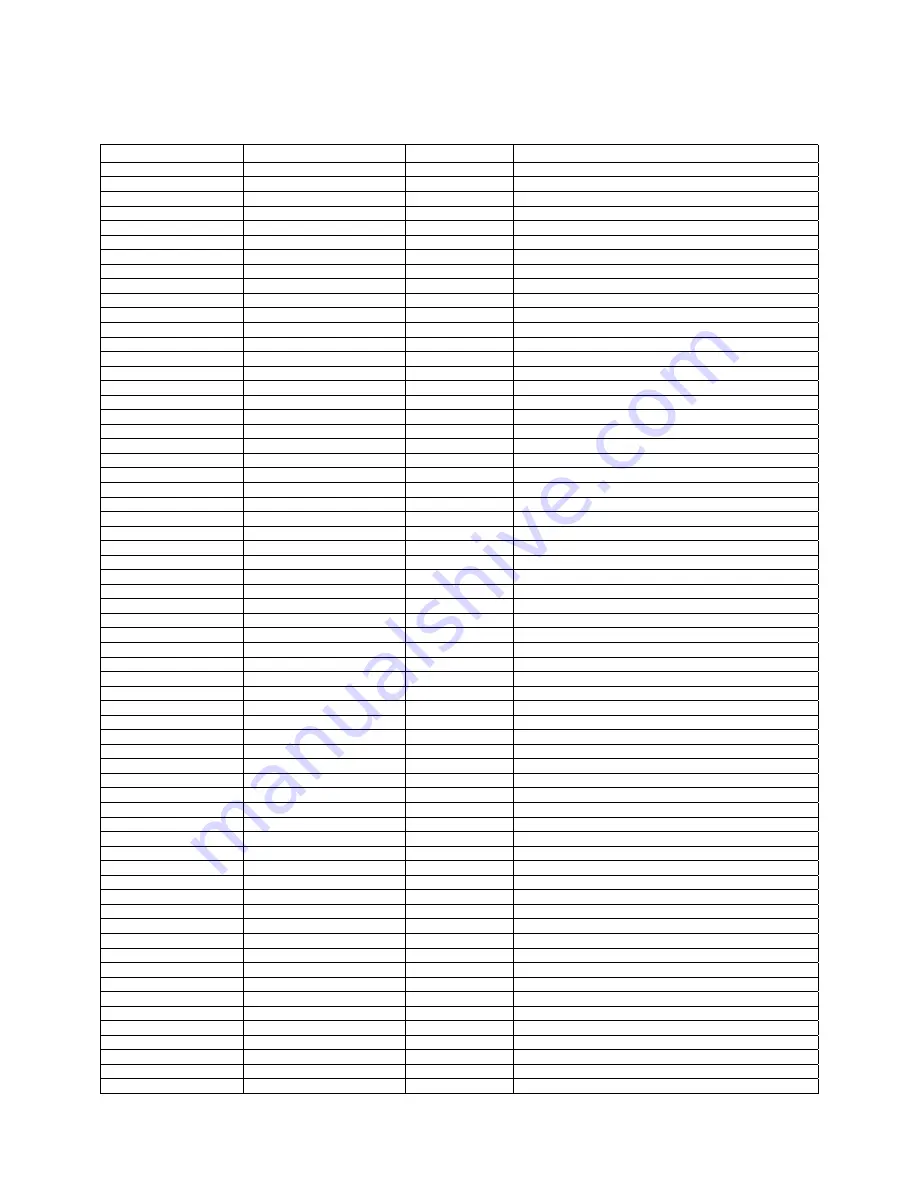

3 5 4 1 RL BI LL OF M AT ERI AL

ITEM NO.

PART NO.

QTY.

DESCRIPTION

1 42814

1

DRUM

2

42812

1 SHAFT

3

42827

6 PIN

4 30567

1

RETAINING

RING

5 30385

1

BEARING,

BALL

6 42828

1

SEAL,

OIL

7 42839

2

RACE

8

4217

1

INPUT GEAR SET

9 41722

2

RACE

10 42203

1

CARRIER

BEARING

11 939452

1

O-RING

12 29967

1

BALL

BEARING

13 42202

1

OIL

SEAL

14 42661

1

BRAKE

HOUSING

15

42803

1

OUTPUT SUN GEAR

16 42663

1

SIDE

PLATE

17 42924

1

AIR

PISTON

18 42201

1

O-RING

19 31455

1

O-RING

20 34003

1

O-RING

21 42943

1

AIR

PISTON

22 42842

1

FRAME,

L.H.

23 42843

1

FRAME,

R.H.

24 30600

1

RETAINING

RING

25 42148

8

STATOR

PLATE

26 32765

7

FRICTION

DISC

27 42220

1

SLIDING

CLUTCH

28 42593

1

BRAKE

COVER

29 42229

1

BRAKE

PISTON

30 42230

12

BRAKE

SPRING

31 13050

1

BREATHER

32 21684

1

PLUG

33 43117

1

MOTOR,

HYDRAULIC

34 42206

1

INPUT

DRIVER

35 32566

1

O-RING

36 33094

1

O-RING

37 26980

2

RETAINING

RING

38 41723

2

RACE

39 41743

2

BUSHING

40 41759

1

CLUTCH

41 41740

1

BRAKE

DRIVER

42 29043

1

RETAINING

RING

43 42217

1

OIL

SEAL

44

42238

1

INPUT SUN GEAR

45 41719

1

PLUG,

O-RING

46 42239

10

CAPSCREW

47 42241

1

SPRING,

CLUTCH

48 33260

1

THRUST

WASHER

49 28060

12

CAPSCREW

50 41000

4

LOCKWASHER

51 41721

2

OIL

SEAL

52

32868

1

ADAPTER, 90 DEG.

53 41838

1

ADAPTER,

STRAIGHT

54 42594

1

MOUNTING

BRACKET

55 42595

1

TUBING

56 41603

1 COUNTERBALANCE

VALVE

57 42596

1

TUBING

58

42597

1

ADAPTER, 90 DEG.

59 42534

1

CABLE

THIMBLE

60

4215

1

OUTPUT GEAR SET

61 42820

1

COVER

62 23521

1

PLUG

63 20522

12

CAPSCREW

64 4218

1

CABLE

PACKER

14

Summary of Contents for Rufnek Intelliguard 3541RL

Page 16: ...16 VISCOSITY CHART...

Page 18: ......