6

USER MANUAL

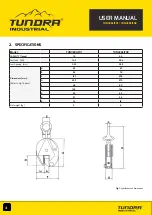

TUNVERLIF01

•

TUNVERLIF02

3.1 ATTACHING THE PLATE

•

Turn the function lever clockwise to disengage the jaws.

•

Then put the plate to the end of the mouth of clamp.

•

Move the function lever counter- clockwise lo grip and lock the plate.

3.2 LIFTING SAFETY

•

Do not lift or transport loads while other personnel are in the work/lift area.

•

Do not stand or place hands or feet under the raised plate.

•

Raised loads are not to be left unattended for a longer period of time.

•

The operator may only start to move the load when he is sure the load will not overturn and that all personnel have

•

left the work area.

3.3 TO LOOSEN LOAD

•

Move the function lever clockwise to disengage the jaws.

4. MAINTENANCE

To maintain continuous and satisfactory operation, a regular inspection procedure must be initiated so that worn or damaged parts

can be replaced before they become unsafe.

If faults are detected the clamp must be put out of service immediately. The intervals of inspection must be determined by the

individual application and are based upon the type of service to which the clamp is subjected.

The components of the clamp are to be inspected for damage, wear, corrosion or other irregularities. Repairs may only be carried

out by trained professionals using Tundra Industrial approved parts. Contact your nearest dealer for advice.

5. PARTS LIST & DIAGRAM

Item

Description

Quantity

Item

Description

Quantity

1

Pivoting Shackle

1

11

Connecting Block Pin

1

2

Rollpin

1

12

Pivoting Shackle Pin

1

3

Connecting Block

1

13

Rollpin

1

4

Body

1

14

Function Block

1

5

Locknut

1

15

Pulling Spring

1

6

Lockwasher

1

16

Rollpin

1

7

Round Jaw

1

17

Connecting Plate

1

8

Screw

1

18

Clamping Jaw

1

9

Roll pin

1

19

Rollpin

1

10

Function Lever

1

20

Jaw Pin

1

21

Shim Washer

1