13

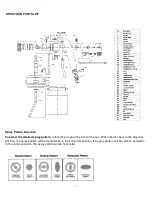

CHANGING THE NEEDLE, NOZZLE AND AIR CAP

Select the needle, nozzle and air cap combination based on the coating being sprayed, the application speed and

finish required. Select the combination that performs best with the trigger fully engaged.

Needles and nozzles are sized together – when changing the needle, the nozzle must be changed as well. Air caps

are sized separately and can be changed without changing the needle and nozzle:

1. To Change The Needle:

Completely unscrew the material flow adjustment screw at the back of the gun and

remove the spring and needle – if necessary, squeeze the trigger to help remove the needle.

2. To Change The Nozzle:

Completely unscrew the air cap ring on the barrel of the gun and remove the air

cap, spring plate, and spring. Using a needlenose pliers, remove the nozzle.

3.

To Change The Air Cap:

Completely unscrew the air cap ring on the barrel of the gun and remove the air

cap.

4.

To re-install the Spring plate

To re-install the spring plate after changing the nozzle and/or air cap:

1. Place the spring in the barrel of the gun.

2. Place the spring plate on the spring with the recessed side inward, and the ball guide lined up with the groove

in the housing.

3. Press the spring plate into the housing, making sure that the ball guide is sliding into the groove in the

housing, and hold it in place.

4. Slide the air cap over the spring plate, and hold it in place.

5. Place the air cap ring on your index finger. Use the tip of the same index finger to hold the air cap on the

spring plate and screw the air cap ring in place.

REPLACING THE CUP TOP GASKET

The cup top gasket on the underside of the cup top should be replaced periodically as part of preventive

maintenance. A worn cup top gasket can be the cause of material leaking from the paint cup and/or bubbling under

the paint cup top when the gun is in use.

To Replace The Cup Top Gasket:

1. Remove the paint cup from the gun.

2. Remove the cup top gasket using a pointed object or screwdriver.

3. Replace with a new gasket, making sure it is placed flat and properly pressed in place.

REPLACING THE GLAND SEAL

The gland seal is located behind the gland nut directly in front of the gun trigger and should be replaced periodically

as part of preventive maintenance. A worn gland seal can be the cause of leaking between the gland nut and the

needle directly in front of the trigger. If leaking occurs, try tightening the gland nut before changing the gland seal.