4

CLEANING

CAUTION

1. CLEANING THE INTERIOR AND EXTERIOR

- The interior and exterior of the unit can be cleaned using warm water with soap.

- Do not use an abrasive cleaner because it will scratch the surface.

2. CLEANING THE CONDENSER FINS

- To maintain proper refrigeration performance, the Condenser coil must be free of

- The pressure switch is installed in the product to protect the compressor. Please

clean the condenser every 90 days or the pressure switch will cut out the unit,

to protect the compressor from high pressure.

dust, dirt, and grease.

This will require periodic cleaning. Condenser fins should be cleaned at least every

three months (90 days) or as needed.

3. CLEAN THE GASKET

- The door gasket should be cleaned frequently to maintain proper sealing.

4. CHECK AFTER CLEANING

- Check the unit again for safety.

- Check that the unit is operating properly.

1. POWER CORD

- Be sure that the power cord is connected to the proper voltage.

- A protected circuit of the correct voltage and amperage must be run for

connection of the line cord.

- Turn ʻoffʼ the power switch before disconnecting the power cord, whenever

performing maintenance functions or cleaning the refrigerated cabinet.

- Compressor warranties are void if compressor

burns out due to low voltage.

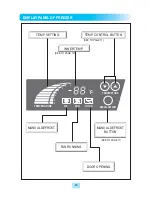

- Dual voltage freezer (PRO-77F, PRO-77-6F) requires

receptacle as shown the right sides.

2. RE-STARTING

- If disconnected, wait for 5 minutes before re-starting.