1

2

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

IMPORTANT NOTES ON YOUR ANTI-LAG VALVE

-

Turbosmart accepts no responsibility whatsoever for incorrect installation of this product which is potentially hazardous and can cause serious

engine damage or personal injury.

-

Antilag produces excessive heat in the exhaust system and may shorten the life of your exhaust manifold and turbo.

-

Consult your local specialist before setting your setting your antilag valve, setting antilag levels beyond your engines capability may result in

engine or turbo damage.

-

Use only high-quality fittings ensuring maximum sealing reliability. Optional Turbosmart fitting kit available.

-

Turbosmart’s ALV valve is recommended for race applications only.

-

It is important during the setup of the eGate, that some precautions are taken to ensure that the unit does not malfunction. Firstly, the output

from the ECU should be limited to 15%. As well as an inline fuse (5A-10A) or breaker to protect the eGate. Once correct operation has been

verified the fuse and limits can be removed.

RECOMMENDATIONS

-

Always disconnect motor wires before removing the top cap of the actuator

-

Allow for adequate cool airflow around electronic actuator.

-

DO NOT Mount the antilag valve so that the electronic actuator is less than 100mm from a heat source.

-

DO NOT wrap the body of the antilag valve with exhaust wrap.

-

Fitting your Gen V antilag valve may require fabrication or modification to your exhaust manifold. Turbosmart recommends that your

antilag valve is fitted by an appropriately qualified technician

.

-

Fitting the ALV to your turbocharger system introduces fresh air into the exhaust system post engine and therefore air fuel ratios will show as

lean.

-

Turbosmart recommends that antilag settings are set using a dynamometer and not on public roads.

-

Turbosmart recommends that a boost gauge be permanently fitted to the vehicle.

------------------------------------------------------------------------------------------------------------------------

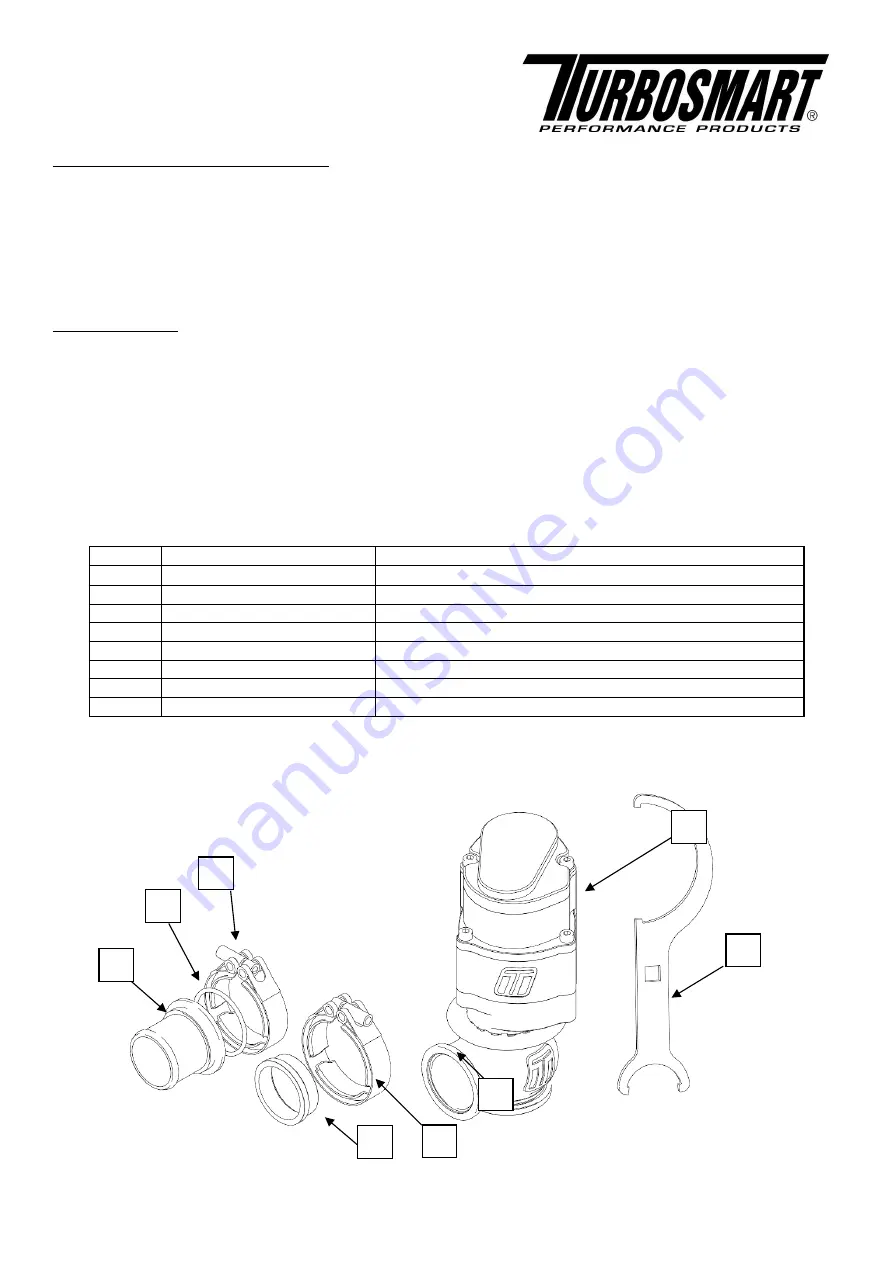

KIT CONTENTS

Please check that the following items have been provided in your Gen V Anti lag valve kit.

Part

Description

Use

1

Turbosmart Gen V Anti lag valve

Main unit

2

Valve Seat

Valve seat

3

Inlet V-Band clamp

Inlet V-band clamp

4

Inlet Hose Adaptor

Inlet Hose Adaptor

5

Outlet V-Band clamp

Outlet V-band clamp

6

Collar tool

Adjusting actuator location

7

Turbosmart Sticker

Turbosmart sticker

8

Inlet O ring

O-ring seal for inlet

Figure 1 - Kit Contents

1

3

4

5

6

Product Name:

Gen V eALV40 Electronic Anti-Lag Valve

Product Description:

Gen V eALV40

Product Number:

TS-0552-16XX

Document Version:

V1.00 Rev A

2

6

8

Important Note: The outlet weld

flange is sold separately, purchase

accordingly, see page 6