6

FITTING YOUR GEN V WASTEGATE

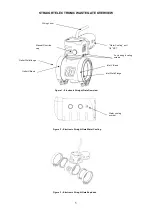

Mounting your new Turbosmart Electronic Straight

Wastegate

Water cooling is highly recommended for sustained heat

exposure.

The weld flanges should be welded to your exhaust system. The

weld flanges are compatible with Stainless Steel and Mild steel

welding rod material.

The Straight Gate utilises WG60 Outlet Flanges, this allows for a

straight swap over for engines running WG60 Valves. A new

exhaust side will need to fabricated for cars running the poppet

valve.

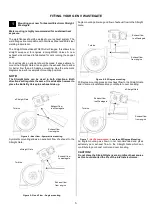

For best results, an attempt should be made, if space allows, to

mount the Straight Gate at an angle to the exhaust flow to allow

for better flow than a 90-degree mounting. See the schematic

diagrams below for examples of mounting positions.

NOTE!

The Straight Gate can be used in both directions. Both

directions will regulate the same. It is advisable however to

place the Butterfly Valve pins exhaust side up.

Figure 4 - Best flow - Symmetric mounting

Symmetric mounting allows an excellent flow of exhaust to the

Straight Gate.

Figure 5 - Good Flow - Angle mounting

Angle mounting allows a good flow of exhaust flow to the Straight

Gate.

Figure 6 - 90 Degree mounting

90 Degree mounting gives poor exhaust flow to the Straight Gate

and in some circumstances may contribute to over boosting.

Figure 7 -

Not Recommended

- Less than 90 Degree Mounting.

An angle mounting as shown in not recommended and gives

extremely poor exhaust flow to the Straight Gate which can

contribute to poor boost control and over boosting.

CAUTION!

Do not place the Straight Gate near a significant heat source

as this could shorten the life of the internal electronics.

1

Turbine

eStraight Gate

Exhaust flow

to eWastegate

Exhaust flow

from engine

Turbine

eStraight Gate

Exhaust flow

to wastegate

Turbine

Exhaust flow

to eWastegate

Exhaust flow

from engine

eStraight Gate

Turbine

Exhaust flow

from engine

Exhaust flow

to eWastegate

Exhaust flow

from engine