18

19

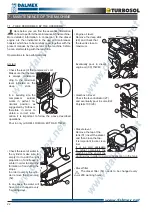

open the tie-rod, remove the inspec-

tion plugs of the delivery valve

(41), remove the rubber

ball valve (42), and pour

some slurry in the valve

body (43).

Then place back the ball

valve and the inspection

plug, finally close tight the

tie-rod and start again.

Put the by-pass lever (20)

in horizontal position: the

machine starts to pump

slurry into the hoses.

Before the slurry is over

pour some prepared

mortar from the mixer to

the vibrating sieve. (S version)

Version with fixed mixer (MF)

Activate the mixer using the control lever (36) and

prepare the mortar.

Load the mixer with sand, cement/

lime and water.

Discharge the mix

on the vibrating

sieve opening the

discharge door with the indicated

lever (44).

The slurry starts coming out of the

spraygun and soonafter the mortar will follow.

Now the machine is in working conditions and can be

stopped using the air cock on the spraygun (15).

Usually, when the machine is

on

stand-by,

the

operator

has to move the by-pass

lever

(20)

in

recycling

position

(vertical).

At the next start up the before mentioned lever has to be

placed in pumping position (horizontal).

In case of long stops, open the discharge cock (38) and

place the by-pass lever in vertical position so that

the mortar can be recycled into the hopper.

Make sure that the mortar in the hopper is always

at such a level to cover the agitator. If the level is not

sufficient the pumping piston (rubber) will suffer a very

fast wear and tear due to the lack of lubrication.

The operator on the spraygun does not have to point the

spraygun towards other people.

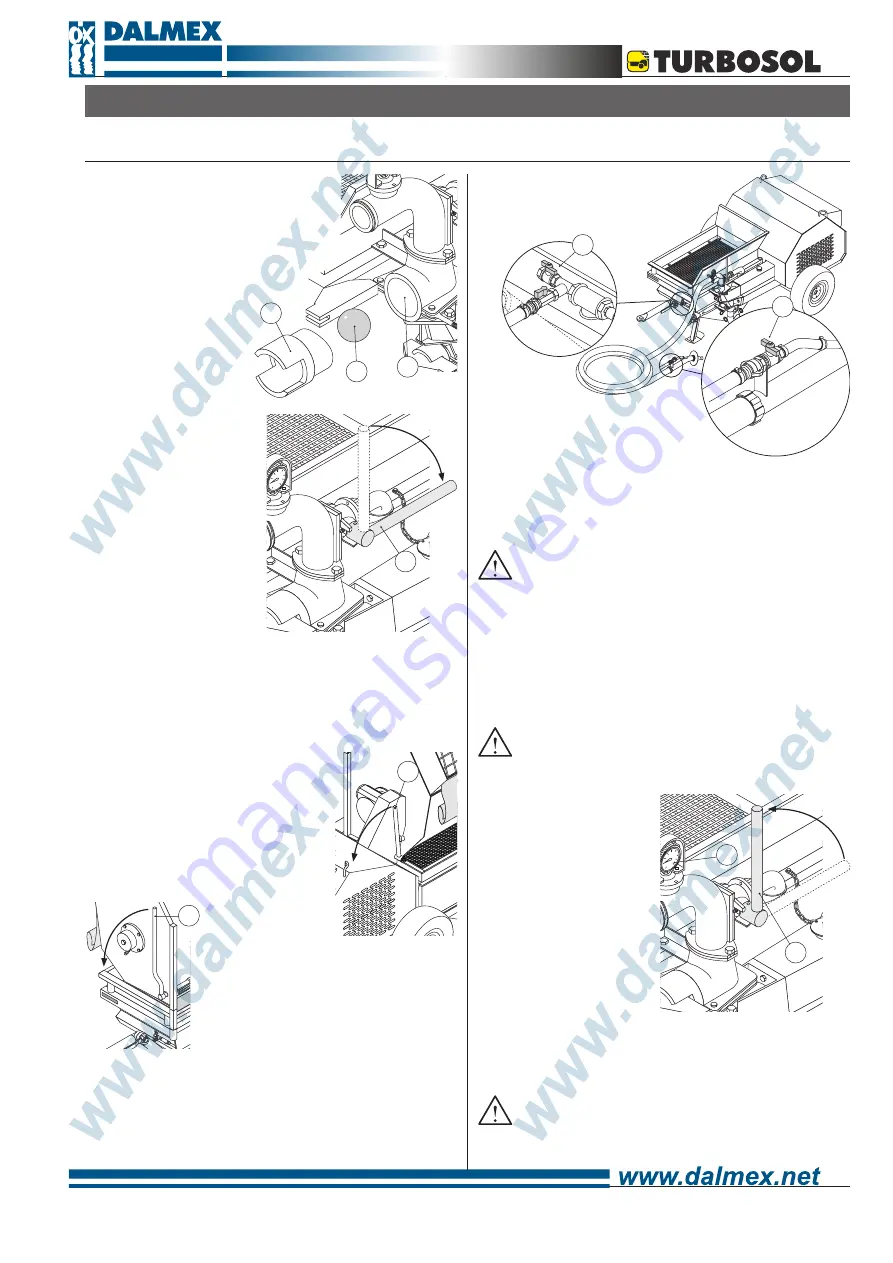

During pumping operations the operator at the machine

should check that the

pressure gauge (45)

(positioned on top of the

pumping group) never

exceeds 20 ÷ 25 bar.

A higher pressure may

indicate a blockage in the

mortar hoses or in the

spraygun. If this happens,

stop the machine and

discharge the pressure in

the hoses turning the by-

pass lever (20) in vertical

position then remove the

blockage (page 28).

In case of blockage of the spraygun, for no reason

whatsoever you should look directly in the hole of

the deflector. The sudden exit of the blocked part

or of mortar under pressure may cause problems

to the sight.

20

36

44

20

38

15

45

42

41

43

Summary of Contents for UNI 30 D

Page 4: ...4 ...