22

23

7 - MAINTENANCE OF THE MACHINE

7.1 - TO BE PERFORMED BY THE OPERATOR

Here below you can find the essential information

on how to perform the maintenance of the machine.

More detailed information in connection to the diesel

engine are then indicated in the use and maintenace

booklet, which has to be carefully read, together with the

present manual, by the operator of the machine, before

he can start working with the machine.

Operarations to be performed daily

At start

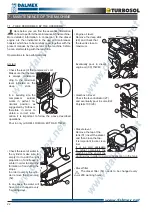

• Check the level of the compressor’s oil:

Make sure that the level

is always correspon-

ding to the maximum

level inticated on the

deep stick.

In a building site the

compressor

seldom

works in perfect ho-

rizontal position as

suggested by Turbosol,

therefore in order to

obtain a correct lubri-

cation it is important to follow the above described

operations.

Pour in only oil SHELL RIMULA EXTRA D 15W40.

• Check the level of water in

the cylinder, make sure to

empty it or to add the right

proportion of antifreeze in

winter in order to avoid the

formation of ice during the

stops.

In order to empty the cylin-

der remove the drain plug

(52).

In any case, the water will

have to be changed every

5 working days.

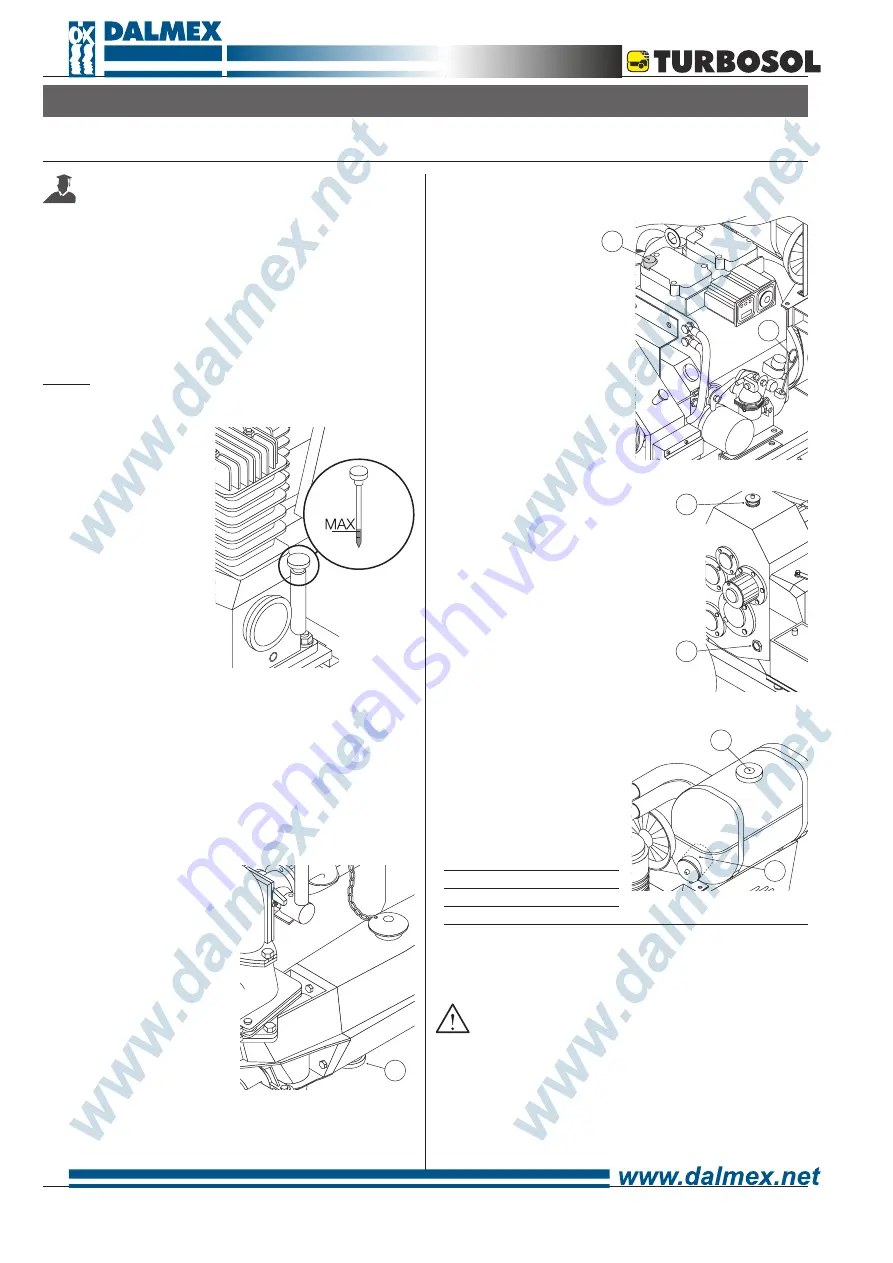

• Engine oil level:

Remove the deep stick

(29) and check that

the level is close to

maximum.

Eventually pour in diesel

engine oil (30) 15W40

• Gearbox oil level:

Check the level indicator (27)

and eventually pour in some ELF

Polytelis 100 (28).

• Diesele lever:

Remove the tap of the

tank (31) insert the diesel

and then close the tap.

It is important to use clean

fuel.

It is as well advisable

to refuel completely the

machine at the end of the

working day in order to avoid condensation in the tank.

• Diesel filter

The diesel filter (53) needs to be changed every

200 working hours.

28

27

29

30

31

52

53

Summary of Contents for UNI 30 D

Page 4: ...4 ...