26

27

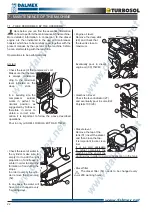

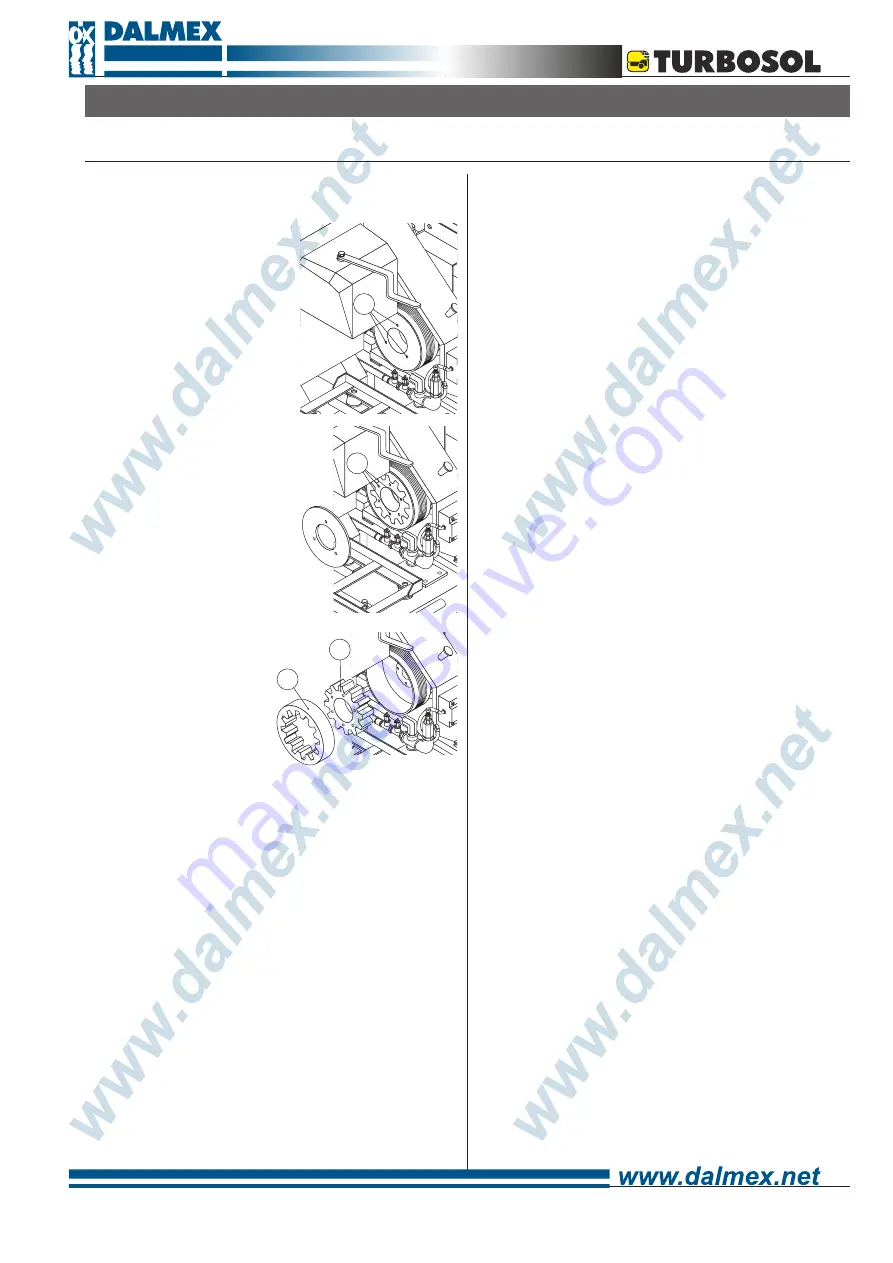

Change of the teethed wheel and the rubber ring of the

centrifugal joint

• Remove the accumulator.

• Remove the cover of the cen-

trifugal joint removing the 3

hexagon head screws (76).

• Remove the teethed wheel

and the rubber ring remo-

ving the three hexagon head

screws (77).

• Remove the teethed wheel

(79), the rubber ring (78) and

replace them.

• Fix the teethed wheel

and the rubber ring with

the three hexagon head

screws (77).

• Mount back the rubber clutch protecion lid of the cen-

trifugal joint fixing the three hexagon head screws (76)

and place back the accumulator.

Operations to be performed every year or every 100

hours

• Change the compressor oil.

Operations to be performed every 200 hours

• Change the diesel filter.

Operations to be performed every 6 months or 500

hours

Check:

• Check the air hoses.

• Check and eventually change the belts.

• Check the piston, the ball valves, the seals, the

pressure gauge, the by-pass, and generally that no

anomalies are present.

• Change the compressor oil

• Change the gearbox oil.

• Change the gearbox mixer oil.

• Follow the instructions indicated on the diesel engine

use and maintenance booklet.

7.3 - TO BE PERFORMED BY THE QUALIFIED

PERSONNEL

76

77

79

78

Summary of Contents for UNI 30 D

Page 4: ...4 ...