Operation

C.

Return the wand back to its holder.

Important:

Contact an Authorized Service

Dealer if the spreader-sprayer fails to operate

properly.

Cleaning the Sprayer

Clean the spray system after

each

spraying session.

Important:

Always empty and clean the sprayer

immediately after each use. Failure to do so may

cause the chemicals to dry or thicken in the lines,

clogging the pump and other components.

To properly clean the spray system:

•

Use three separate rinses.

•

Use a minimum of 5 gallons (19 L) for each rinse.

•

Use the cleaners and neutralizers as recommended

by the chemical manufacturers.

•

Use pure clean water (no cleaners or neutralizers)

for the

last

rinse.

WARNING

Do Not clean spray nozzles by mouth or blowing

through them. Swallowing or inhaling chemicals

could cause serious injury or death.

Replace all worn and damaged nozzles.

Make sure nozzles are installed correctly.

1.

Drive the machine to a designated cleaning area.

2.

Stop the spreader-sprayer on a level surface, leave

the motion control lever in the neutral position,

and turn off the engine. Engage the parking brake.

3.

Fill the tank with clean fresh water and close the

cover.

4.

Start the engine.

5.

With the motion control lever in neutral position,

engage the pump, and set the engine throttle to

“FAST”.

6.

Set the three spray valves to “ON”.

7.

Allow the water in the tank to spray out through

the nozzles.

8.

Check the nozzles to ensure that they are all

spraying correctly.

9.

Remove the wand from its holder and point it in a

safe direction.

10.

Squeeze the spray wand trigger to release the

pressure.

11.

Return the wand to its holder.

12.

Set the spray control levers to the “OFF” position,

disengage the pump, and stop the engine.

13.

Clean the strainer located in front of the right

tank. Close the tank supply valve. When removing

the canister, drain any unused chemical from the

line and dispose of it according to local codes and

the chemical manufacturer's instructions.

Important:

If you used wetable powder

chemicals, clean the strainer after each tank

rinse.

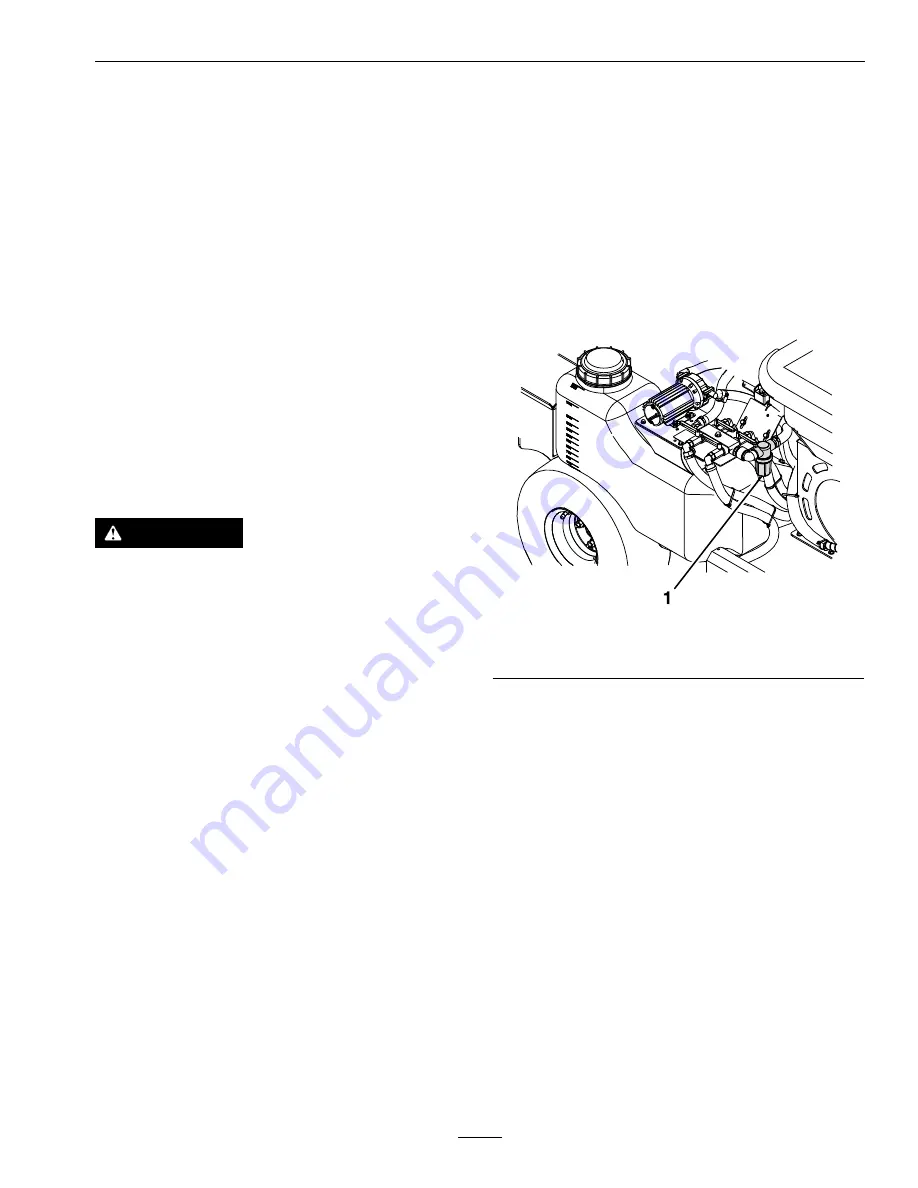

g314218

Figure 26

1.

Strainer

14.

15.

Using a garden hose, spray off the outside of the

sprayer tank with clean water.

Note:

Do Not use a power washer to clean the

machine. The high pressure water may force

residual corrosive materials into spreader-spreader

components.

16.

Remove the nozzles and clean them by hand.

Replace damaged or worn nozzles.

17.

Allow the spreader-sprayer to completely dry

before the next use.

Calibrating the Sprayer Flow

Note:

Before using the sprayer for the first time,

change nozzles, or as needed–calibrate the sprayer

flow and speed.

Note:

Refer to the chemical product label for

application rate recommendations.

31