© Trynex International 2009 L1302

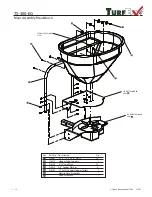

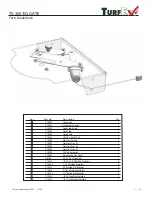

Assembly Instructions (refer to digram on page 1-9)

Step 1:

Attach hopper tube support (D 6712) to complete drive assembly using (4) 5/16"-18 x 1-3/4" hex bolt (D 6462)

and (4)

5/16" lock nut (D 6138)

. Use (2) holes at bottom end of tube.

Step 2:

Place spreader gate deck (D 6706) upside down on table.

Step 3:

Assemble gate indicator/stop (D 6703)

on stop slide with gate knob (D6302) . Gate stop must be on the inside of deck where

it will stop the track.

Step 4:

Insert (1) 5/16 bolt with hole (D 6308) through gate slide (D 6705) . Finger tighten (1) 5/16" locknut (D 6138) on bolt.

Step 5:

Take bulkhead cable fitting (D 6305)

and screw it onto T-handle cable - 10' (D 6304)

rubber coating.

Step 6:

Place assembly through tab on gate deck. Tighten down with supplied washer and nuts.

NOTE: There should be a nut on either

side of tab.

Step 7:

Lower gate assembly over spinner shaft. Spinner shaft must go through 5/8" hole on deck. Shaft to be centered in hole.

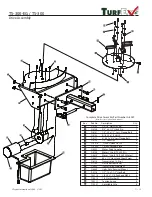

Step 8:

Fasten deck to hopper tube using (4) 5/16" hex bolts (D 6462) and (4) 5/16" locknuts (D 6138)

NOTE: You must first

tighten bottom bolts, pull front of deck up, then tighten top set of bolts.

Step 9:

Place hopper (D 6709)

on deck. 5/8" hole must be used for spinner shaft.

Step 10:

Finger tighten (2) 5/16 x 1" bolts (D 6166) through bottom of hopper.

Step 11:

Place (4) flat washers (D 4318) over hex bolts (D 6462). Place bolts through hopper back and in through tube support.

Tighten with (4) 5/16" locknuts.

Step 12:

Tighten bolts in bottom of hopper.

Step 13:

Place agitator (D 6405) on spinner shaft. Tighen to middle of flat with short allen key.

Step 14:

Attach receiver mount (D 6485) to transmission weldment (D 6480) using (4) 1/2" hex bolts (D 4116) and (4) 1/2" lock

nuts (D 4 120).

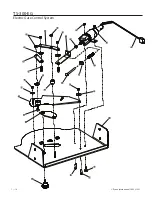

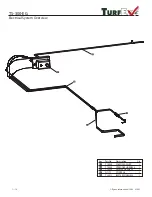

CABLE INSTALLATION

Step 1:

Place unit on vehicle where it will be permanently used. Place hitch pin in hitch so unit does not move.

Step 2:

Route T-handle to desired operating location. There cannot be any bends or sharp corners.

Step 3:

Take T-handle out of sleeve. Take nuts and washer off of sleeve.

Step 4:

Drill holes to mount T-handle mounting bracket. Mount T-Handle to bracket.

Step 5:

Close gate slide all the way.

Step 6:

Re-insert cable handle and wire all the way. Aim through bolt with hole and tighten bolt.

1 — 10

TS-300

R

Summary of Contents for TS-1200-E

Page 8: ... Trynex International 2009 L1302 1 8 TS 300 Main Assembly Views R ...

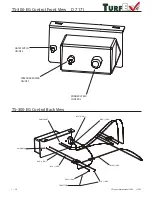

Page 14: ... Trynex International 2009 L1302 1 14 TS 300 EG Electric Gate Control System ...

Page 16: ... Trynex International 2009 L1302 1 16 TS 300 EG Gate Assembly Views R ...

Page 17: ... Trynex International 2009 L1302 1 17 TS 300 EG Front Rear Assembly Views R ...

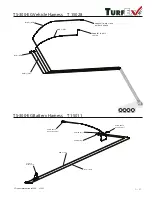

Page 28: ...TS 700 GR TS 1200 GR Main Frame Assembly Trynex International 2009 L1302 1 28 R ...

Page 30: ... Trynex International 2009 L1302 1 30 R TS 700 GR TS 1200 GR Drive Assembly ...

Page 34: ... Trynex International 2009 L1302 1 34 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 35: ... Trynex International 2009 L1302 1 35 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 40: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 40 THIS PAGE INTENTIONALY LEFT BLANK ...

Page 41: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 41 THIS PAGE INTENTIONALY LEFT BLANK ...