CALIBRATION DISCLAIMER

© Trynex International 2009 L1302

1 — 39

R

It is the responsibilty of the person using this equipment to make sure that every type of

material is properly calibrated to perform as expected. This process should take place on a solid

flat surface away from drains and livestock areas in order to achieve a safe and accurate reading

for proper material distribution. Failure to do so may cause an over/under application that could

damage turf areas or give an ineffective pest control treatment. Any calibration charts contained in

this manual are given as a refernce point only and should not be used as an absolute condition.

Spending a few extra minutes to properly calibrate will not only save on wasted materials and time

but also protect turf and other vegitation. Below are several points to be aware of before operating

your spreader in the field.

. Flow rates of chemicals can change for many reasons

1. Formualtions vary within the same brand or even between brannds

2. Formulations vary between batches or dates of manufacture

3. Humidy can cause the material to clump and flow poorly

4. Poor spreader maintenance can cause flow changes

5. Slide stop has moved or calibrated to another type of material

6. Human error can cause rate miscalculation

. Items needed for calibriation

1. A way to catch the material for weighing

2. A device to measure distance

3. A scale to weigh your product

4. A stop watch or other means to time

. Conversion

1. To convert pounds per 1000 square feet to pounds per acre, multiply your rate by 43.6

. Other important information

1. 1 acre is equal to 43,600 Squre Feet

2. Ground speed is very important to keep in mind when doing calculations, you will want

to convert mph to feet per minute

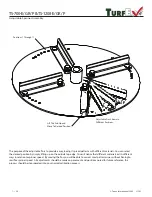

Set the spreader stop at mid point on it’s travel length as a starting point. Fill the hopper with enough

material to cover a known area of 1000 square feet. Open the gate and make note of the start/stop

time, this is very important. Next weigh the material on a scale, divide the weight by the known area

to establish an application rate. You may have to adjust the gate stop for more or less material

depending on your results.

Summary of Contents for TS-1200-E

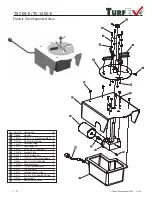

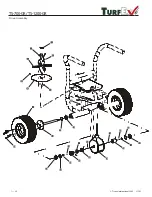

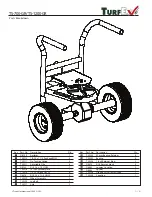

Page 8: ... Trynex International 2009 L1302 1 8 TS 300 Main Assembly Views R ...

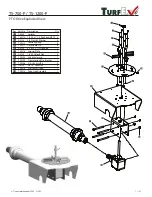

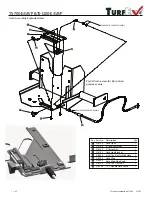

Page 14: ... Trynex International 2009 L1302 1 14 TS 300 EG Electric Gate Control System ...

Page 16: ... Trynex International 2009 L1302 1 16 TS 300 EG Gate Assembly Views R ...

Page 17: ... Trynex International 2009 L1302 1 17 TS 300 EG Front Rear Assembly Views R ...

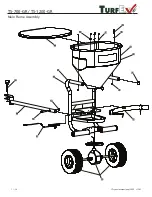

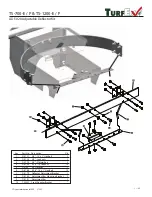

Page 28: ...TS 700 GR TS 1200 GR Main Frame Assembly Trynex International 2009 L1302 1 28 R ...

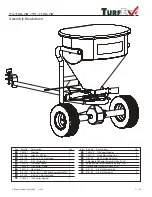

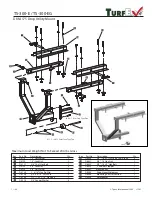

Page 30: ... Trynex International 2009 L1302 1 30 R TS 700 GR TS 1200 GR Drive Assembly ...

Page 34: ... Trynex International 2009 L1302 1 34 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 35: ... Trynex International 2009 L1302 1 35 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 40: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 40 THIS PAGE INTENTIONALY LEFT BLANK ...

Page 41: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 41 THIS PAGE INTENTIONALY LEFT BLANK ...