7

4. When installing a tool to the robot, be sure to turn OFF the power supply on

the control cabinet and the installed tool and lock the power switch, and

hang a warning sign. If the power is turned on during installation, it may

cause electric shock or abnormal movement of the robot, which may cause

injury.

5. Before operating the robot, press the emergency stop button on the front

door of the electric control cabinet and the upper right of the teaching

programmer to check whether the "Servo Ready" indicator is off, and

confirm that the power is turned off.

1.3.5 Gearbox danger

Overview: When lubricating the reducer, it may cause injury to people and equipment,

so before refueling, the following safety information must be waited for.

Warnings and measures:

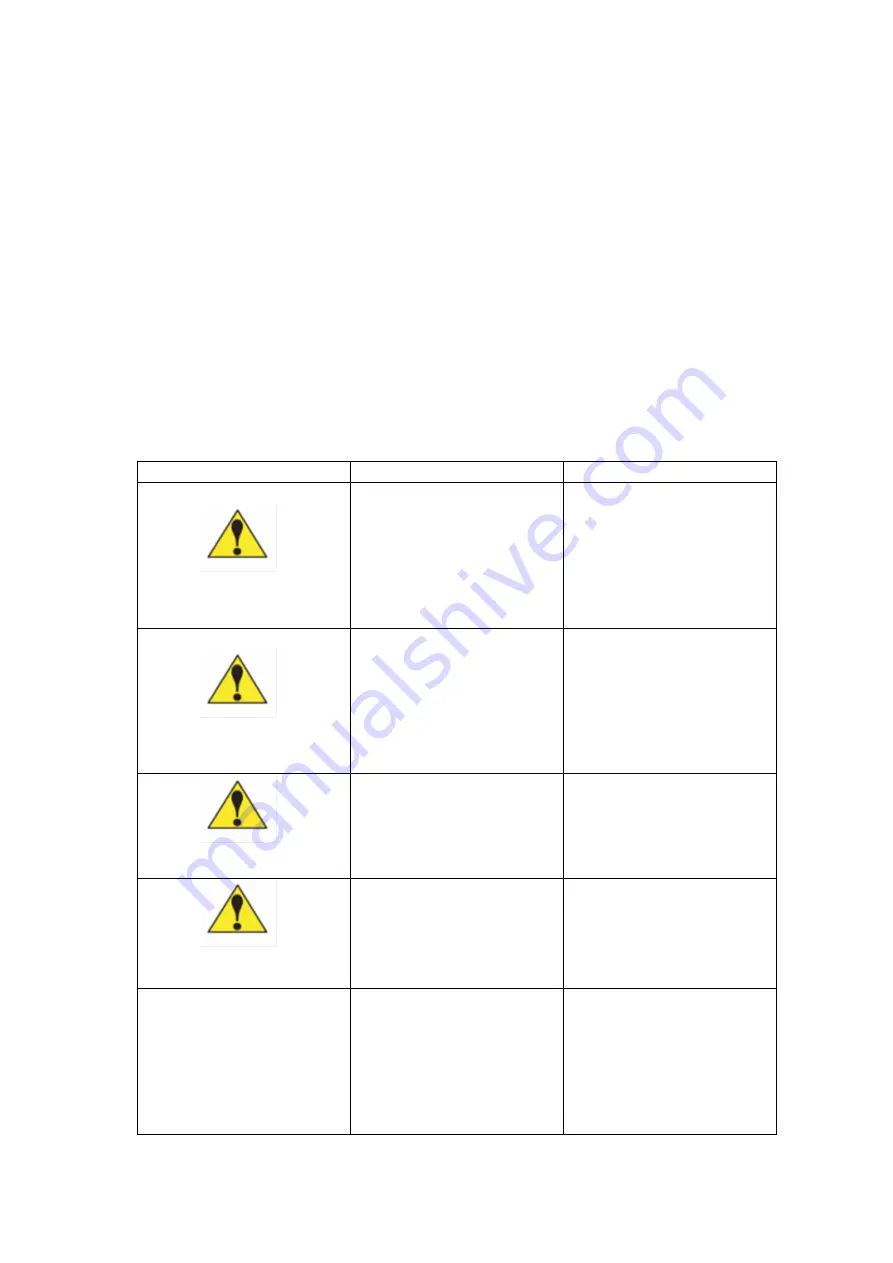

Warning

Description

Measure

High temperature oil or

reducer

When refueling or draining

oil,

sometimes

it

is

necessary to operate the oil

or reducer at a high

temperature of 90 degrees,

and the operator may be

allergic to the oil.

Therefore, wear protective

measures (gloves) to carry

out this work.

Beware of sputtering

When opening the oil

chamber, there may be

pressure in the oil chamber

to cause sputtering

So be careful

when

opening the oil chamber

cover, and stay away from

the opening, do not fill too

much

when

refueling,

according to the amount of

oil.

No top up

Adding too much oil in the

reducer can easily cause

high pressure in the

reducer and damage the

reducer.

When refueling, follow the

instructions or follow the

instructions, and check

after completion.

Prohibition

of

mixing

lubricants

Different types of oil

cannot be added to the

same reducer.

Always use the same type

of oil, if you want to

change to clean up the

previous oil.

Suggest

Hot oil has a lower density

than cold oil and flows

faster.

Before draining the oil in

the reducer, you can run

the robot to heat the oil for

a period of time. It is

easier to drain the oil, or

you can blow it with an air

gun.