OPERATING INSTRUCTIONS

11/26/2019

6

Installation

Securely mount the heater before wiring.

▪

WARNING

: THE INLET AIR/GAS SIDE OF THE HEATER IS THE PLASTIC HOUSING END WHERE THE

POWER TERMINALS AND THERMOCOUPLE TERMINAL BLOCK IS LOCATED. INSTALLING THE

HEATER IN THE WRONG ORIENTATION WILL DAMAGE THE HEATER AND CAN CREATE

ADDITIONAL HAZARDS AS A RESULT. POWER CONNECTION WIRE SIZES ARE RECOMMENDED IN

THE PRODUCT TABLE ABOVE. THESE ARE RECOMMENDATIONS ONLY, AND ALL LOCAL AND

REGIONAL ELECTRICAL CODES SHOULD BE CONSULTED.

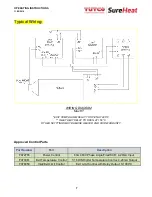

The following is a typical and recommended setup for the Max

HT Heater. The Type “K” thermocouple sensors

mounted outside the Max HT provide flexibility and safety for use with various control systems.

➢

Wire heater according to WIRING DIAGRAM shown. Follow applicable electrical codes when mounting and

wiring system.

➢

The configuration shown is recommended by TUTCO SureHeat for safe and optimum performance.

1. Note THREE (3) control devices are required for proper and safe heater operation, and should be mounted in an

appropriate control cabinet:

i.

MAIN TEMPERATURE CONTROL

•

Controls the heater process temperature

•

Can be 4-

20mA output, or “Pulsed DC” output (0-10V, 3-32V, etc.)

•

Output type will depend on type of POWER CONTROL chosen.

•

Set to

1652

o

F (900°C) MAXIMUM

to prevent overshooting and element failure.

•

A low temperature test run is suggested to verify the closed loop control (PID) settings are

properly set. Overshoot and oscillating process temperature should be avoided to ensure long

heater element life. (Contact the factory for assistance if needed)

ii.

INLET PRESSURE/FLOW SWITCH CONTROL

•

Shuts the MAIN TEMP CONTROL output signal off is the heater is not supplied enough airflow.

•

The MINIMUM airflow needed to avoid damaging the heater is 18 SCFM (510 SLPM)

iii.

POWER CONTROL

•

Regulates the AC voltage to the heater.

•

Select according to heater maximum voltage, and amperage.

•

Suitable POWER CONTROL types:

1.

“Zero-Cross Solid State Relay (SSR), (Pulsed DC Input) - or –

2.

“Phase-Angle” Fired Silicon Controlled Rectifier (SCR) (4-20mA Input)

2. NOTE ON SENSOR CONNECTION

i.

Type “K” thermocouple connects to EXIT TEMPERATURE CONTROL using Type “K” thermocouple wire.

ii. Note that YELLOW is POSITIVE and RED is NEGATIVE for these Thermocouple connections.

3. NOTE ON POWER CONNECTIONS (L1, L2, L3, H1, H2, H3)

Power connection wire sizes are recommended in the Heater Models and Parts List located on page 3. These are

recommendations only, and all local and regional electrical codes should be consulted.

i. LINE TO POWER CONTROL Fuses must be appropriately sized for maximum heater current.

4. NOTE ON TEMPERATURE CONTROLS

i. The AC power source should be taken from the incoming line power (transformed as appropriate).

ii. The AC power source to the Temperature Controls should be energized simultaneously with power to the

Power Control. This is usually done via circuit breaker or power disconnect switch on main control

cabinet.