OPERATING INSTRUCTIONS

11/26/2019

8

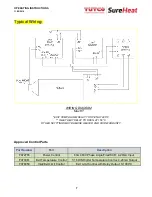

Operation (with Heater)

START-UP

1. Reference the Performance Curves section

(see page 9)

for operational parameters before attempting to

operate heater(s).

2. Connect air source to heater.

3. Turn on air and set pressure or flow to desired operating level.

4. Energize MAIN POWER line; usually via disconnect switch or circuit breaker on control cabinet.

5. During operation, with constant airflow, the exit temperature will vary only a few degrees from set point.

The heater should never be operated without airflow as excessive heat will damage either the element(s)

and/or the plastic housing on the inlet side. The minimum airflow for the SureHeat® Max-HT is 18 SCFM.

Recommendation for first time Start-up: A low temperature test run is suggested to verify the closed

loop control (PID) settings are properly set. Overshoot and oscillating process temperature should be

avoided to ensure long heater element life. (Contact the factory for assistance if needed).

6. If using a closed loop system, turn on power to the temperature and power controller, then set the desired

temperature on the temperature controller. It is recommended to use a ramp rate to set point. The

approved TUTCO SureHeat temperature controllers have a ramp rate function. (Typical recommendation

is 3 to 5 minutes). If using an open loop system, increase power to the heater through the power

controller until the desired temperature is attained.

SHUT-DOWN

1. Turn off MAIN POWER line via disconnect switch or circuit breaker.

2. Allow air to continue to flow for a minimum of 1 minute or until exit air temperature is 300°F (150°C) or

less for safety. Continue airflow longer as necessary to prevent burn hazard to personnel.

3. Turn off air to the system.