6

Thorough Cleaning (refer to exploded view)

Thorough Cleaning (refer to exploded view)

Thorough Cleaning (refer to exploded view)

Thorough Cleaning (refer to exploded view)

Thorough Cleaning (refer to exploded view)

If meter is plugged due to hardened chemical or debris, do

the following:

1. Drain all fluid from meter.

2. Unscrew meter cap (item 1). Use a strap type oil filter

wrench or large 5" jaw pipe wrench if necessary.

3. Insert a flat-head screwdriver in the lower slot (see Figure 7)

and turn to pry up meter cover (item 6).

3. Remove old batteries and insert new batteries, making sure

battery polarity is correct, or meter damage could occur.

4. As noted in Figure 5, reinstall o-ring on electronics module.

Align sensor receptacle in proper location. Press module

gently down into meter cover.

Figure 6

1/8" GAP

CAP

RIDGE ON

OUTLET PORT

5. Thread on meter cap until hand tight. To check tightness,

there should be 1/8" gap between cap and ridge on outlet

port. (See Figure 6).

O-Ring

Figure 5

REPAIR

If any meter components are damaged, they should be re-

placed. See meter drawing and parts list for correct replace-

ment part number before ordering.

Meter should be flushed between uses with water to prevent

chemicals from drying and plugging meter.

MAINTENANCE

Follow fluid manufacturer's recommended procedures

for handling and disposing of metered fluids.

CAUTION

Figure 7

Lower Pry Slot

4. The meter chamber (item 8) can now be removed.

5. Rinse all meter components with flushing fluid. Do NOT

submerge display assembly. Be careful not to get any fluid

or dirt in the electronics module.

6. Reassemble meter.

CALIBRATION NOTE: Over time, the chamber inside the 825

meter will wear, requiring the meter to be recalibrated with

water. When this should be done depends on the

amount and type of fluid dispensed. In most crop protection

fluid uses (less than 1000 gallons of a clean fluid per year), the

825 meter will remain accurate for many years without

recalibration. On the other hand, dispensing an abrasive

fluid may require more frequent recalibration.

The 825 meter is designed to be calibrated with clean water

for safe handling. See "Water Calibration" section in Appen-

dix-B.

NOTE

: Low battery icon will flash when batteries begin to

lose power. Meter still functions properly for several days after

the icon begins to flash. Neither calibration, current total or

totalizer quantities will be lost when replacing batteries.

To Replace Batteries

To Replace Batteries

To Replace Batteries

To Replace Batteries

To Replace Batteries (refer to exploded view)

1. Unscrew meter cap (item 1). Use a strap type oil filter wrench

or large 5" jaw pipe wrench if needed.

2. Insert a flat-head screw driver into the top slot (see Figure

4) and gently pry up electronics module.

CAUTION: Be careful not to get fluid or dirt in electronics area.

Figure 4

Upper Pry Slot

CHANGING THE CAL FACTOR

CHANGING THE CAL FACTOR

CHANGING THE CAL FACTOR

CHANGING THE CAL FACTOR

CHANGING THE CAL FACTOR

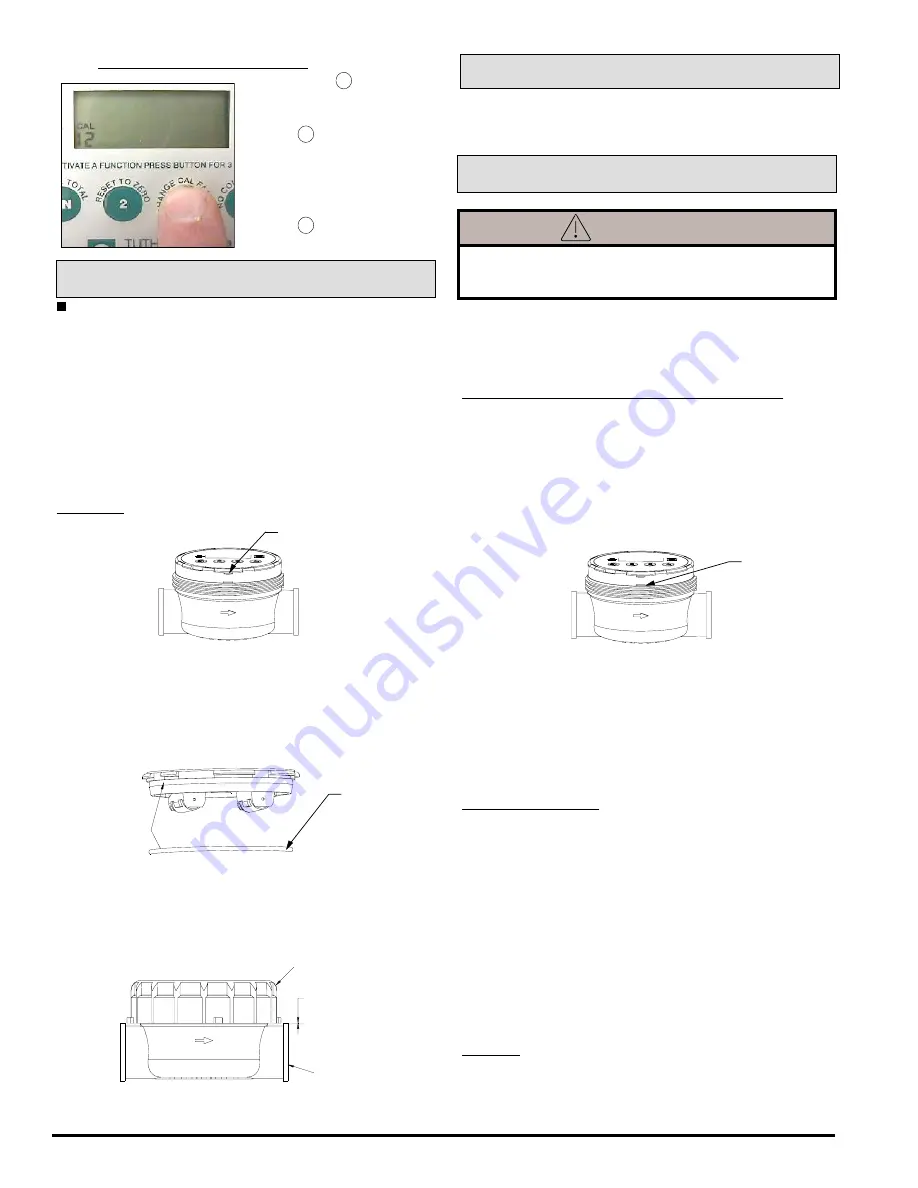

• Hold button 3 until the

display only shows CAL and

number.

• Press 3 repeatedly until

you reach the desired

number. Note – number will

increment up to 19, then

back to zero.

• Press 2 to return to

normal operating mode.

Storage

Storage

Storage

Storage

Storage

Store in a cool, dry place. Drain out all fluid that could freeze

in the meter.

BATTERIES