5

INSTALLATION INSTRUCTION

STEP 1

: (Selecting Site) Before installing your new lift, check the following:

1.

LIFT LOCATION: Always use architects plans when available. Check layout dimension against floor

plan requirements making sure that adequate space is available.

2.

OVERHEAD OBSTRUCTIONS: The area where the lift

is to be

located should be free of

overhead

obstructions such as heaters, building supports, electrical lines etc.

3.

DEFECTIVE CONCRETE: Visually inspect the site where the lift is to be installed and check for

cracked or defective concrete.

4.

FLOOR REQUIREMNETS: The lift should be installed on a 3000 PSI concrete with little gradients.

STEP 2

: (Unloading and Unpacking)

1.

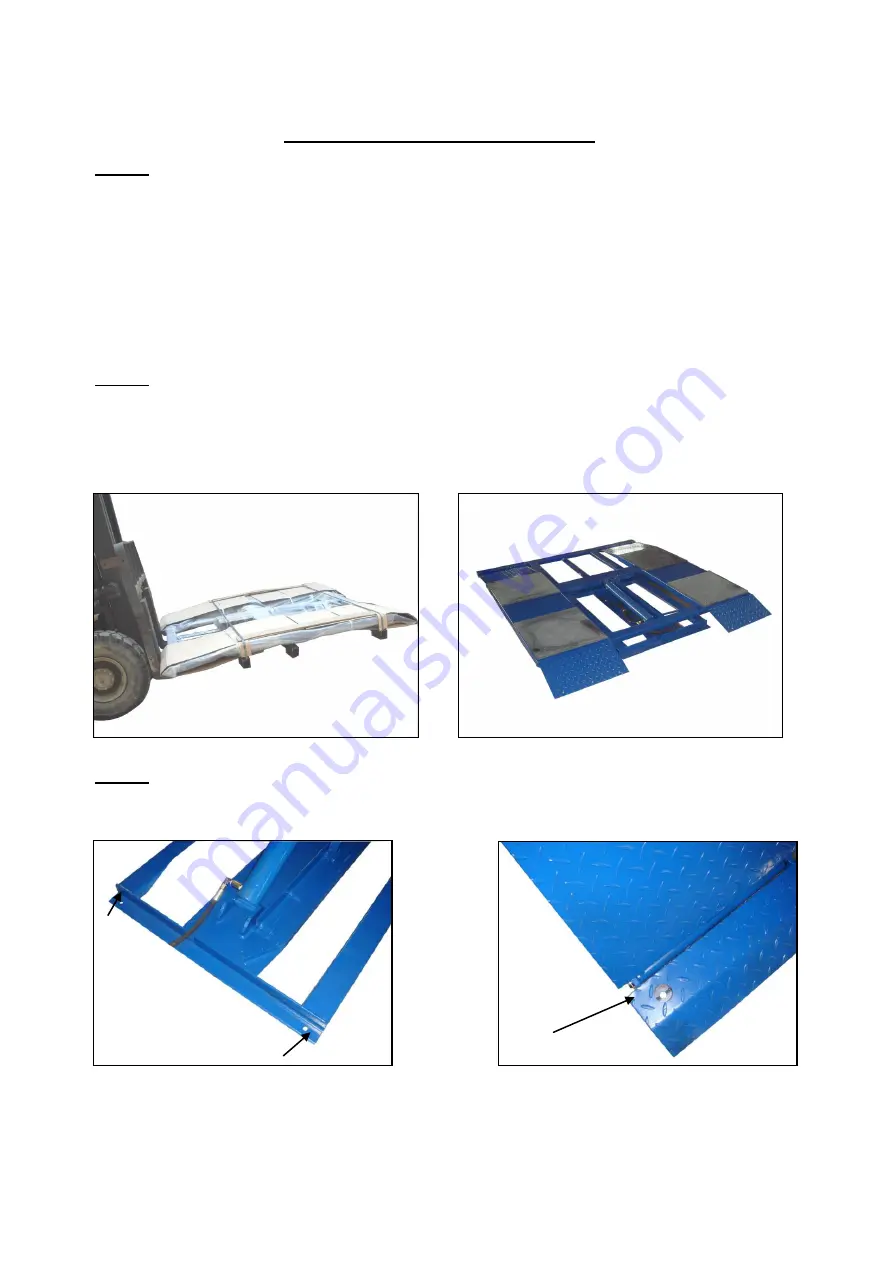

The lift package can be lifted with a fork lift in both directions. (Fig1)

2.

After unloading the lift, place it near the intended installation location.

3.

Remove the shipping bands and packing materials from the unit. ( Fig 2)

4.

Take out the rubber pads from the package. If any

thing is

missing, please contact your dealer.

Fig 1

Fig2

STEP 3

: (Anchoring)

1.

Drill each anchor hole in the concrete approximately 5

1

/

2

” deep using a rotary hammer drill and

3

/

4

”

concrete drill-bit. (Fig 3 & Fig. 4)

Fig 3

Fig 4

2.

Assemble the washers and nuts on the anchors then tap into each hole with a block of wood or

rubber hammer until the washer rests against the base plate.

REV A-090413

Summary of Contents for LR-26-PAD

Page 3: ......

Page 10: ...9 LIFT PARTS DRAWING AND PARTS CODE LIST 161106 Fig 1 0100 FRAME Fig 18 REV A 090413 ...

Page 12: ......