23

TP9KACX / TP9KSCX

Jan 2017

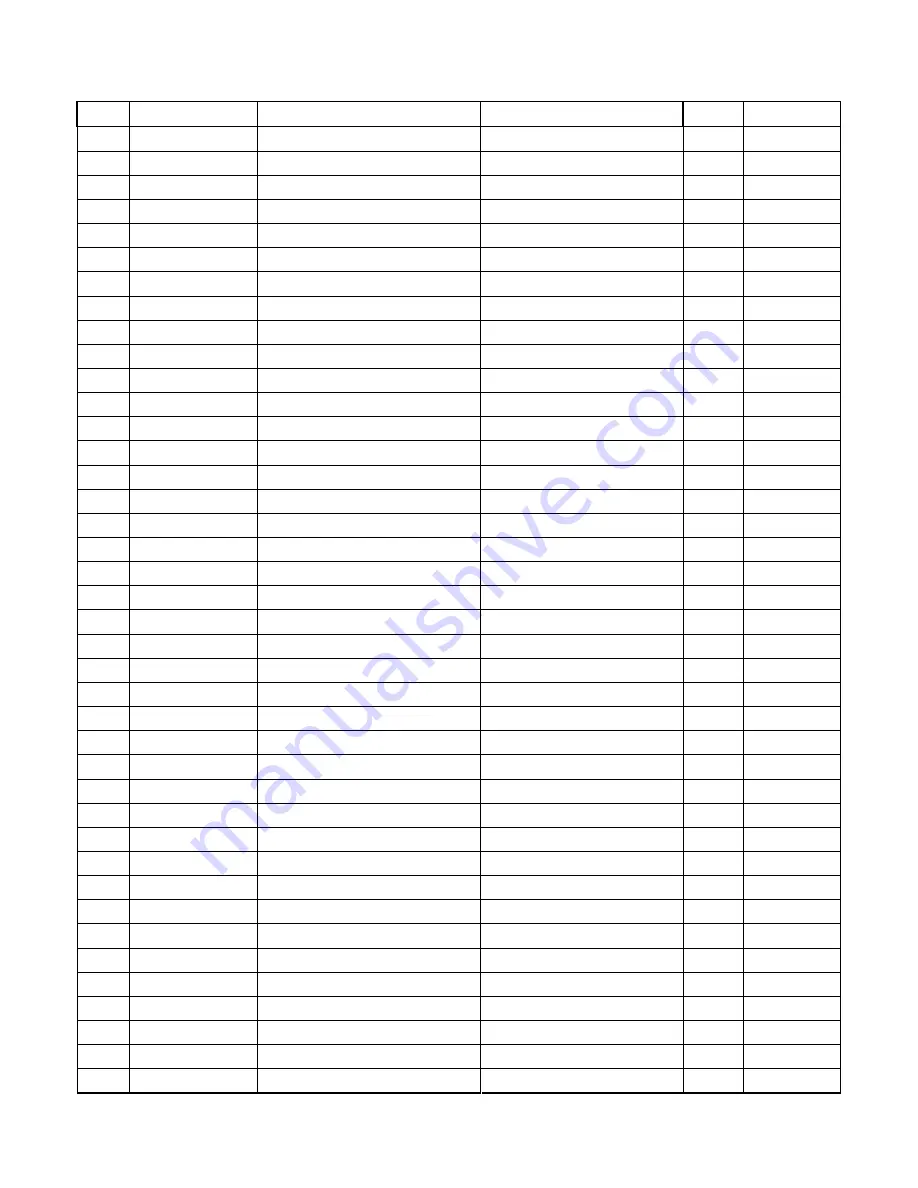

PARTS LIST

ITEM

Tux P/N

M-Ref P/N

DESCRIPTION

QTY

NOTES

1

TP9KACX-001

TT-6835-100-00AKY

Mainside Column

1

2

TP9KACX-002

TT-6835-100-00BKY

Offside Column

1

3

TP9KACX-003

TT-6934-400-10-00KY

High Adaptor 4”

4

4

TP9KACX-004

TT-6934-400-09-00KY

Low Adaptor 1-3/8”

4

5

TP9KACX-005

TT-6835-100-03

Cable Nut

1

6

TP9KACX-006

TT-6934-100-14KY

Adaptor Bracket

2

Q235

7

TP9KACX-007

GB818-85 M8X10

Bolt M8x10

4

8

TP9KACX-008

GB95-1985 D8

Flat Washer D8

4

9

TP9KACX-009

Anchor Bolt

10

10

TP9KACX-010

TT-6835-400-05K-00BMKY

Front / Short Asy. Arm-PS

1

Passenger

11

TP9KACX-011

TPF4-400-04-00

Saddle Pad weldment

2

12

TP9KACX-012

TPF4-400-01A

Rubber Pad, Saddle Pad

2

Rubber

13

TP9KACX-013

GB819-2000 M8X12

Screw M8x12

4

14

TP9KACX-014

TT-6934-046405772

Rubber Pad, Swivel Pad

4

Rubber

15

TP9KACX-015

TT-6934-048417190LKY

Swivel Pad weldment

4

16

TP9KACX-016

TT-6934-048417160KY

Swivel Pad, Screw Collar

4

45

17

TP9KACX-017

GB/T895.2-1986 D28

Circlip D28

4

18

TP9KACX-018

TT-6835-400-05K-00BMKY

Front / Short Asy. Arm-DS

1

Driver

19

TP9KACX-019

TT-6835-400-05-00MKY

Rear / Long Asy, Arm

2

Rear

19A

TP9KACX-019A

TT-6934-400-00MDKY

Sym. Arm (TP9KSCX)

4

TP9KFX/SX

20

TP9KACX-020

TPF4-400-06-00

Swing Arm Pin

4

21

TP9KACX-021

GB70.1-2000 M8X35

Screw

4

22

TP9KACX-022

DL38G-C116A

Rubber Door Guard

2

23

TP9KACX-023

DL38G-C109A

Sliding Rub Block

16

24

TP9KACX-024

TT-6934-200-01-00KY

TP9KX Carriage

2

25

TP9KACX-025

TT-6934-200-02

Plastic Cover, Carriage

4

ABS

26

TP9KACX-026

Pull Knob, Arm Restraint

4

Plastic

27

TP9KACX-027

GB97.2-85 D10

Washer D10

8

28

TP9KACX-028

GB93-87 D10

Washer D10

4

29

TP9KACX-029

GB6170-2000 M10

Nut M10

4

30

TP9KACX-030

TPF4A-200-11-04

改

Gear Bar, Arm Restraint

4

31

TP9KACX-031

TPF4-200-11-05

Plate, Arm Restraint

4

Q235-A

32

TP9KACX-032

qys-200-17

Spring

4

65Mn

33

TP9KACX-033

GB91 d2.5X14

Split Pin D2.5x14

4

34

TP9KACX-034

TPF4A-200-11-01

Rod, Arm Restraint

4

Q235-A

35

TP9KACX-035

TPF4-300-00

Lock Latch

2

36

TP9KACX-036

GB95-1985 D20

Flat Washer D20

2

37

TP9KACX-037

GB818-2000 M6×30

Screw M6x30

2

38

TP9KACX-038

TPF4-300-09

Spring

2

65Mn

39

TP9KACX-039

TPF4-100-12

Plastic Cover, Column

2

PVC 0.007

Summary of Contents for TP9KACX

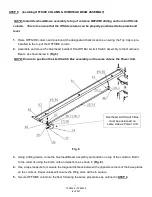

Page 4: ...4 TP9KACX TP9KSCX Jan 2017 ...

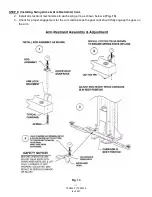

Page 6: ...6 TP9KACX TP9KSCX Jan 2017 Fig 2a TP9KACX Asymmetric Lift Fig 2b TP9KSCX Symmetric Lift ...

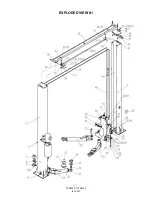

Page 21: ...21 TP9KACX TP9KSCX Jan 2017 EXPLODED VIEW 1 ...

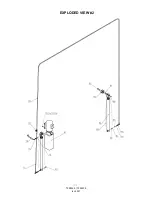

Page 22: ...22 TP9KACX TP9KSCX Jan 2017 EXPLODED VIEW 2 ...

Page 26: ...26 TP9KACX TP9KSCX Jan 2017 ...